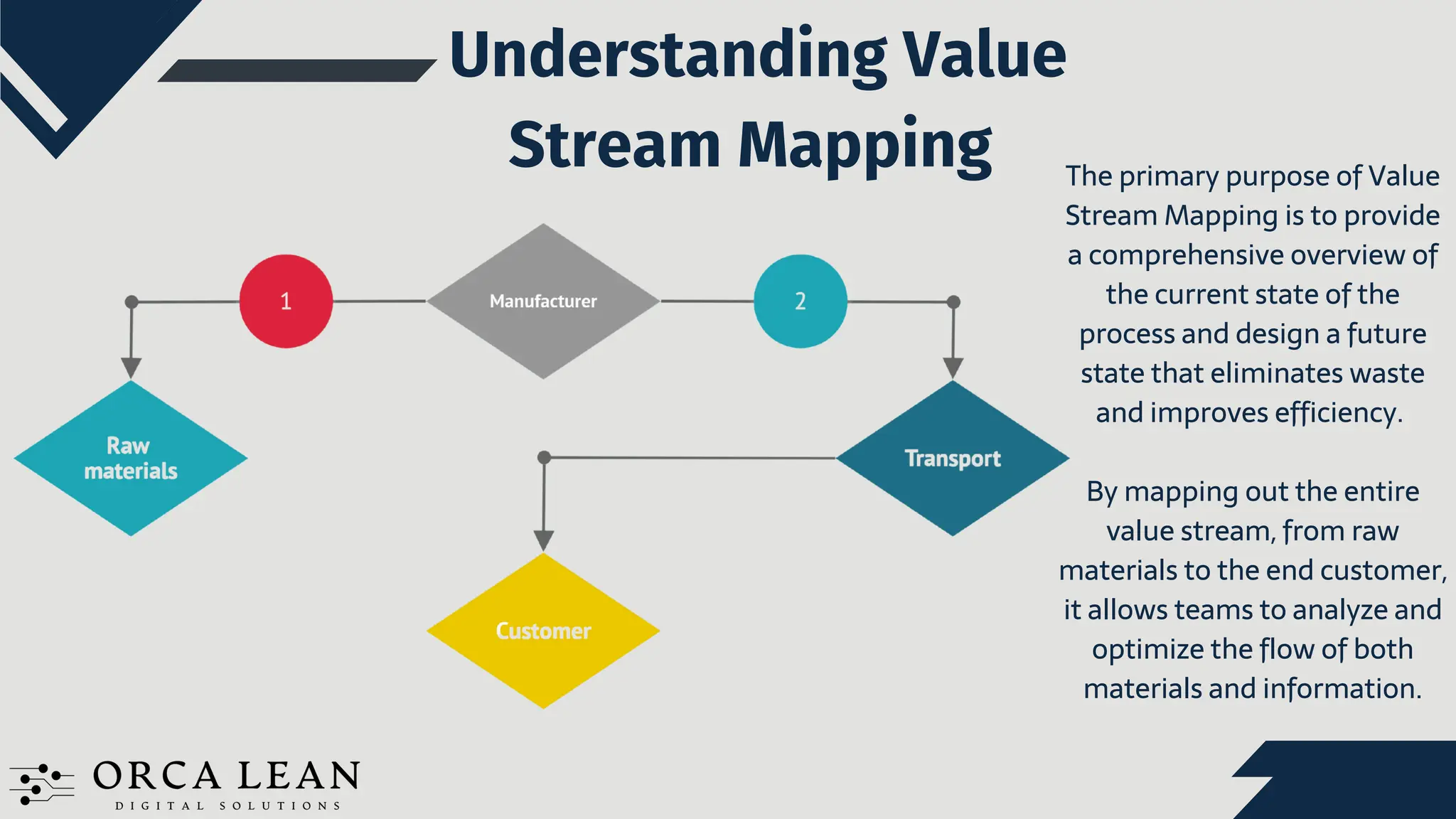

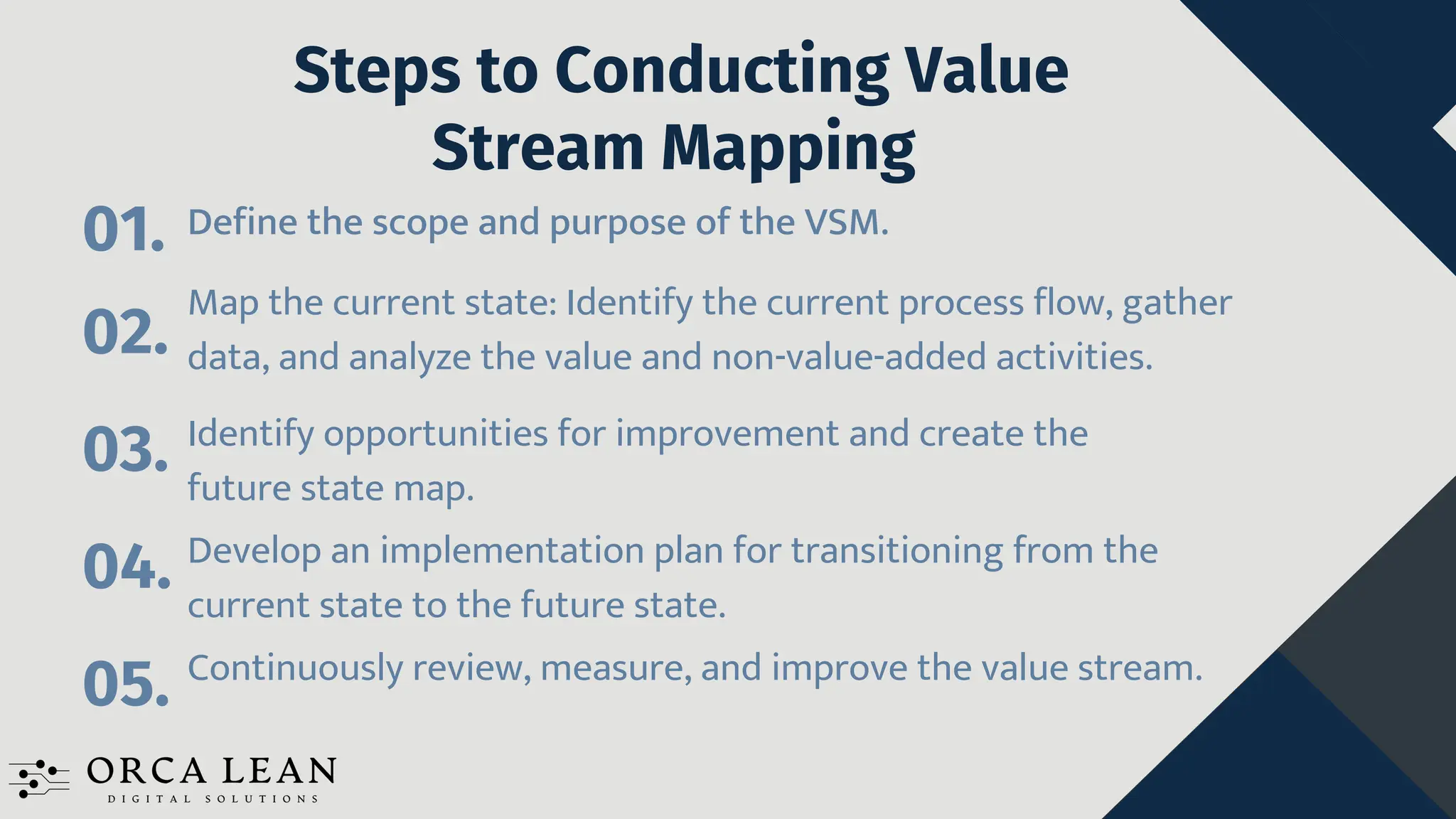

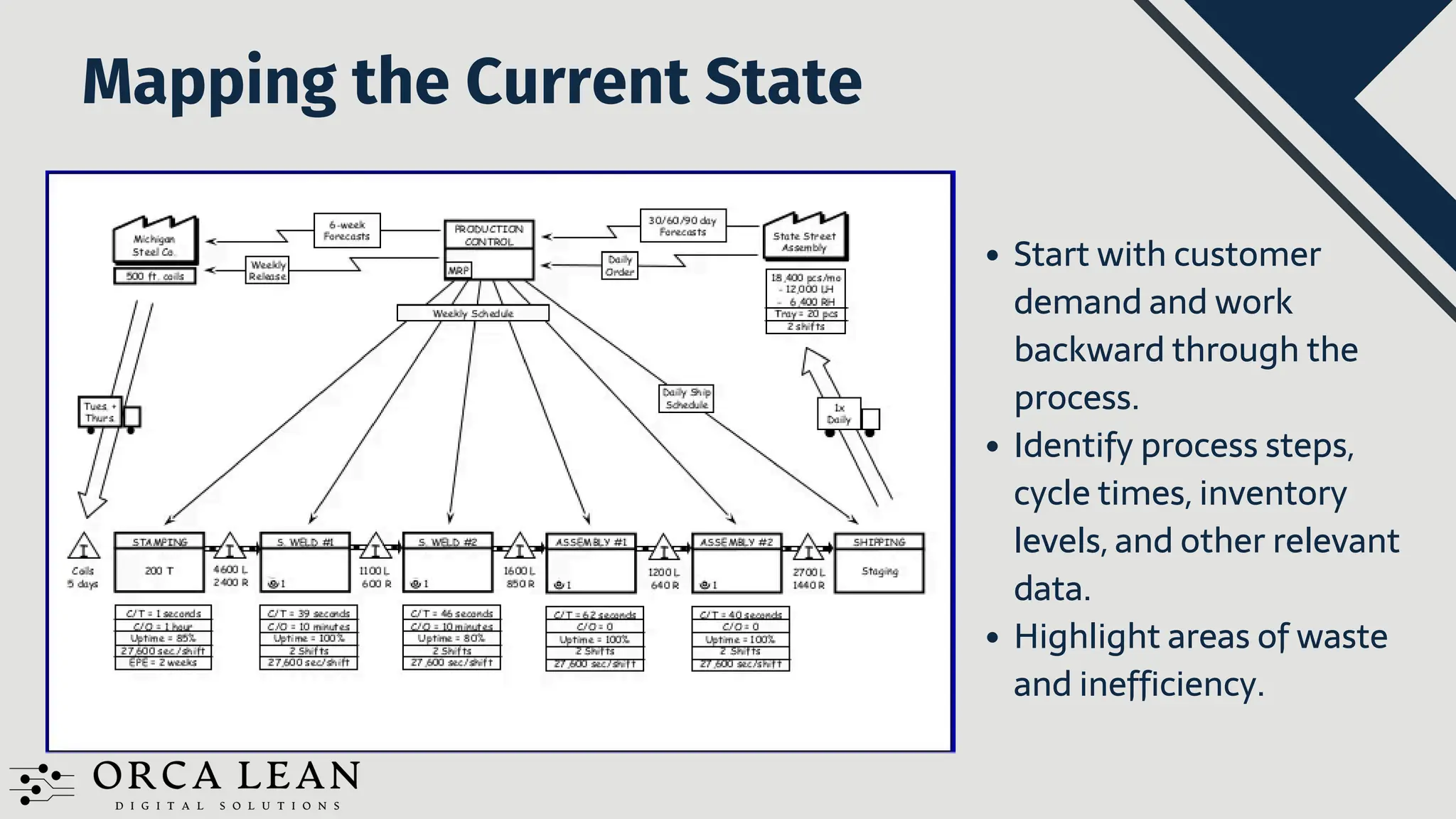

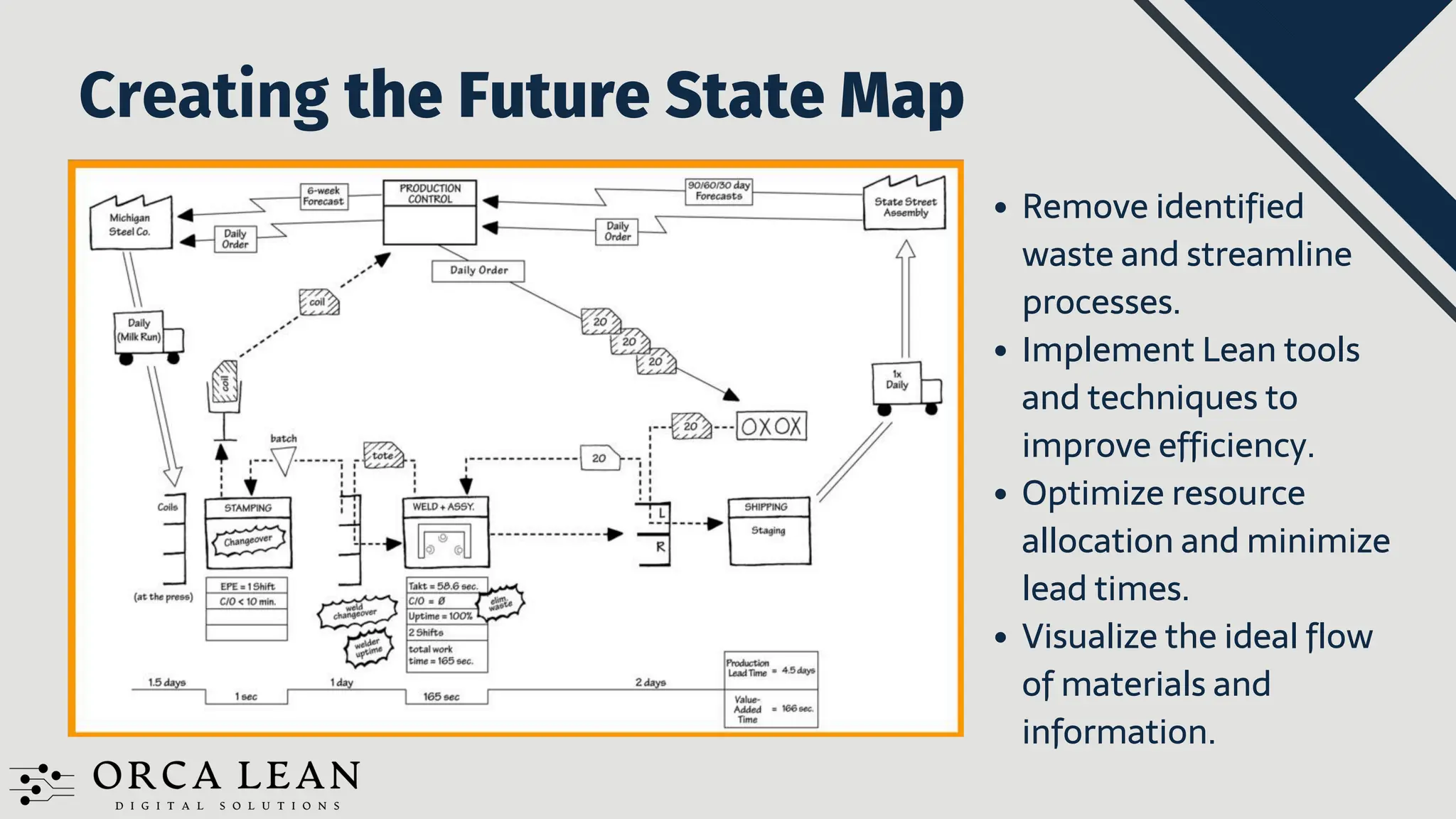

Lean manufacturing focuses on waste elimination to enhance productivity and quality, leveraging processes like value stream mapping. This process involves mapping current workflows to identify inefficiencies and develop future state maps that improve resource allocation and streamline operations. Successful examples, such as Toyota, demonstrate significant reductions in lead times, improved cash flow, and increased employee engagement through lean practices.