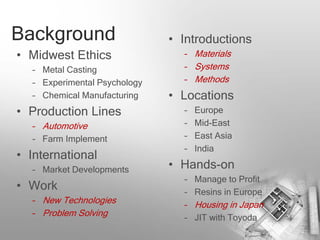

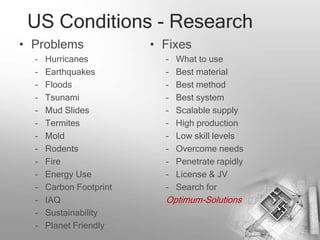

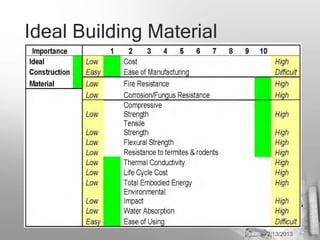

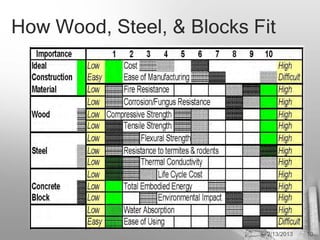

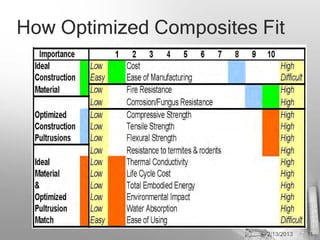

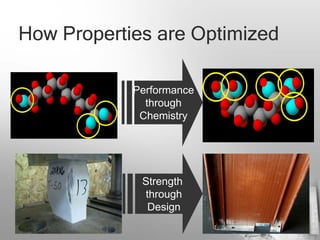

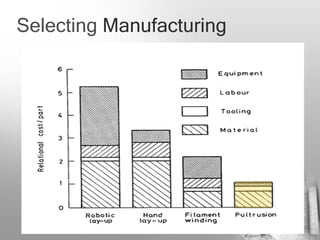

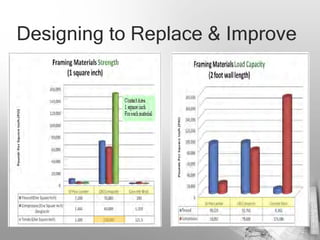

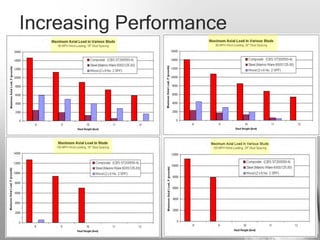

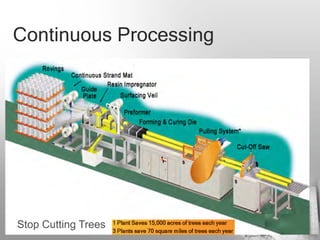

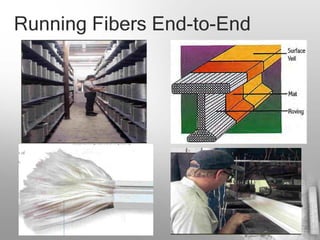

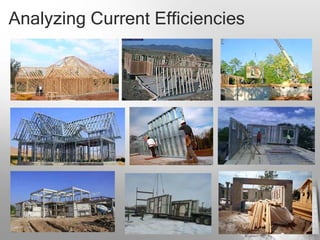

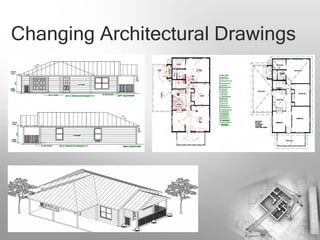

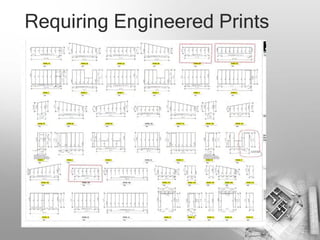

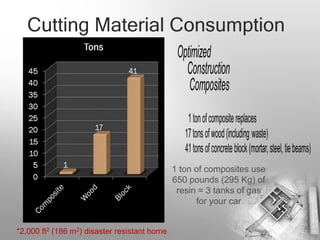

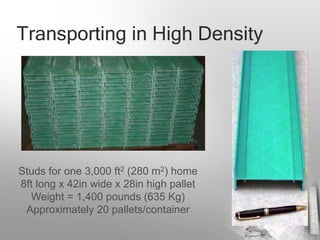

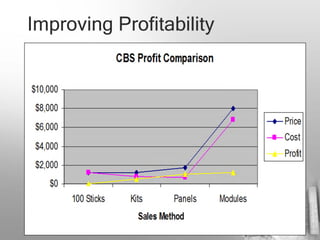

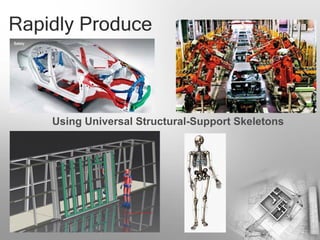

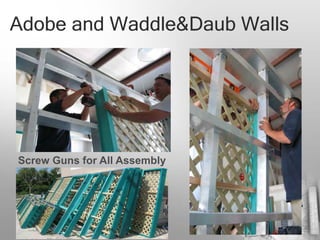

The document discusses the need for updating and improving the building industry through a holistic approach that integrates materials, methods, and systems, emphasizing the use of composites as a key technology. It identifies challenges such as inefficiencies, environmental concerns, and outdated practices that must be addressed for sustainable progress. The document advocates for continuous improvement and innovative building practices to enhance profitability and quality in construction.