The document describes an innovative opposed piston engine concept called the Paul Engine that could achieve unprecedented levels of fuel efficiency and power density. Key aspects include using opposed pistons without a cylinder head to improve efficiency, utilizing high compression ratios and supercharging, and incorporating heat recovery from the exhaust and cooling systems. Experimental prototypes demonstrated efficiencies over 50% and power densities up to 600 kW/L. Further developments aim to adapt the concept for automotive and other applications through modifications like a four-stroke cycle and integrating heat recovery into a compact design. The innovations have the potential to revolutionize engine technology by substantially reducing fuel consumption, emissions, weight, and cost.

![3

It comprises two opposing pistons per module, with two lateral crankshafts, each cylinder having two pistons moving in opposite directions. This innovative design configuration eliminates the cylinder- head and valve-train components of conventional engines, offering an efficient engine structure. In conjunction with the thermal efficiency advantage inherent to opposed-piston engines, this concept realizes significant reductions in fuel consumption over conventional four-stroke compression ignition engines. The disadvantages are: -The scavenging of the cylinder is made by an external compressor, electrically acted, which present an important cost. - It has a complex construction. - Not four-stroke solution proposed.

PAUL ENGINE – THE MOST EFFICIENT ENGINE EVER BUILT

The engine concept is based fundamentally on thermodynamic laws, which provide an undeniable solid basis for this development. The main thrust of this new engine concept is to produce the highest pressure thermal cycle possible. The pressure achieved are well above those obtained in current state-of-the-art of 120 to 180 daN/cm². The engine concept discussed here is pushing pressures to the new frontiers: 300 to 350 daN/cm². Consequently it employs real compression ratio between 30 to 60:1 (with high supercharging ratio) and ideal cycle efficiency of:

In the last time, few experimental works, done by some independent prestigous research entities, demonstrated in paralel this posibility for compression ignition engine [4]:](https://image.slidesharecdn.com/ultimateic-enginetechnology-141210051618-conversion-gate02/85/Ultimate-IC-engine-technology-3-320.jpg)

![4

And for spark ignition engines [5]:

These digrams from [4] and [5] don’t take into account the heat recovery from the exhaust gases and from the cooling system.

To attain these goals it is necessary to overcome basic conceptual design and structural barriers that have blocked further advances in engine technology for the past 100 years.

The main barriers that have been eliminated are: 1. The cylinder head, valves and valve mechanism ; 2. The side force between piston and cylinder liners; 3. The piston rings with high back pressure; 4. The truncated expansion stroke; 5. The heat losses.

The Paul concept is based on structural and fundamental principles which are: 1. Opposed piston engine – without cylinder head, gasket, valves, etc. 2. Ultra-high compression ratio and supercharger level; 2. Counter rotating mechanism, eliminating the side force and improving engine balance; 3. Piston rings without back pressure; 4. Extended expansion stroke using in the most efficient manner the combustion gas energy; 5. Symmetrical active force clamping the block and the opposed crankcases, pre-compressed by longitudinal bolts. By pre-loading the engine, the pre-compressed structure of the block and the crankcases are relaxed during combustion, creating an enormous capacity for high peak pressure and high power density.

This advanced engine technology was demonstrated by Engine Corporation of America, the project being sponsored by the U.S. Department of Defense through the Defense Advanced Research Project Agency (DARPA), implicating Sandia, Los Alamos and Lawrence Livermore National Laboratories and a group of U.S. Universities.](https://image.slidesharecdn.com/ultimateic-enginetechnology-141210051618-conversion-gate02/85/Ultimate-IC-engine-technology-4-320.jpg)

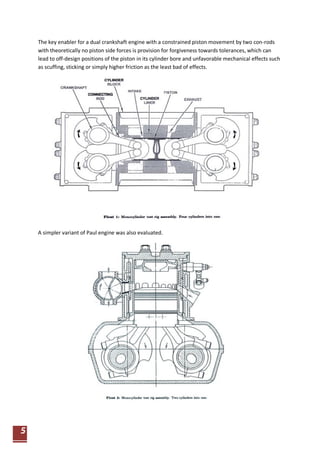

![6

The demonstrated engine advances that result from this research are: 1. Highest power density between 300 to 600 kW/l; 2. Reduced CO2 level; 3. Compensation of all rotating inertial forces; 4. Compensation of all 1st order oscillating forces (torque compensation); 5. No reaction due to torque impulses on the exterior of the engine are detectable; 6.Very low friction losses from the guidance of the piston by the connecting rods (the lateral guiding force of the piston is effected by the connected rods); 7. The use of large swept volumes with better thermodynamic efficiency; 8. Lowest fuel consumption between 95 and 125 g/kWh; 9. A dramatic reduction in cost of production and exploitation; 10. Universal use, i.e., military or commercial.

The recently demonstrated values have established new frontiers that are now opening the possibility of achieving enormous increases in power density and efficiency in future engines. An early operational prototype of Paul engine is shown below:

Almost 20 years ago (in 1996), this variant already obtained 52% Brake Mean Efficiency and a huge power density, without heat recovery,

Some versions of Paul Engine are successfully used to capture and to re-distribute the wind/solar renewable energies or even nuclear energy. One of these applications works in space from 20 years.

FIRST CIVIL EXPLOITATIONS OF PAUL MECHANISM

Due to their high efficiency, low weight and economic fuel consumption as well as their unbeatably low vibration, a German company NEANDER began to build multi-cylinder or mono-cylinder four- stroke Diesel engine using Paul mechanism, considered ideal for many leisure and commercial applications [3]. FEV North America, Inc. a leading developer of advanced powertrain and vehicle system technologies, which collaborated in the past with Dr. Paul, showcased a turbo-diesel outboard marine engine developed in cooperation with Neander Motors AG at the SAE World Congress 8-10 April at COBO Center in Detroit.](https://image.slidesharecdn.com/ultimateic-enginetechnology-141210051618-conversion-gate02/85/Ultimate-IC-engine-technology-6-320.jpg)