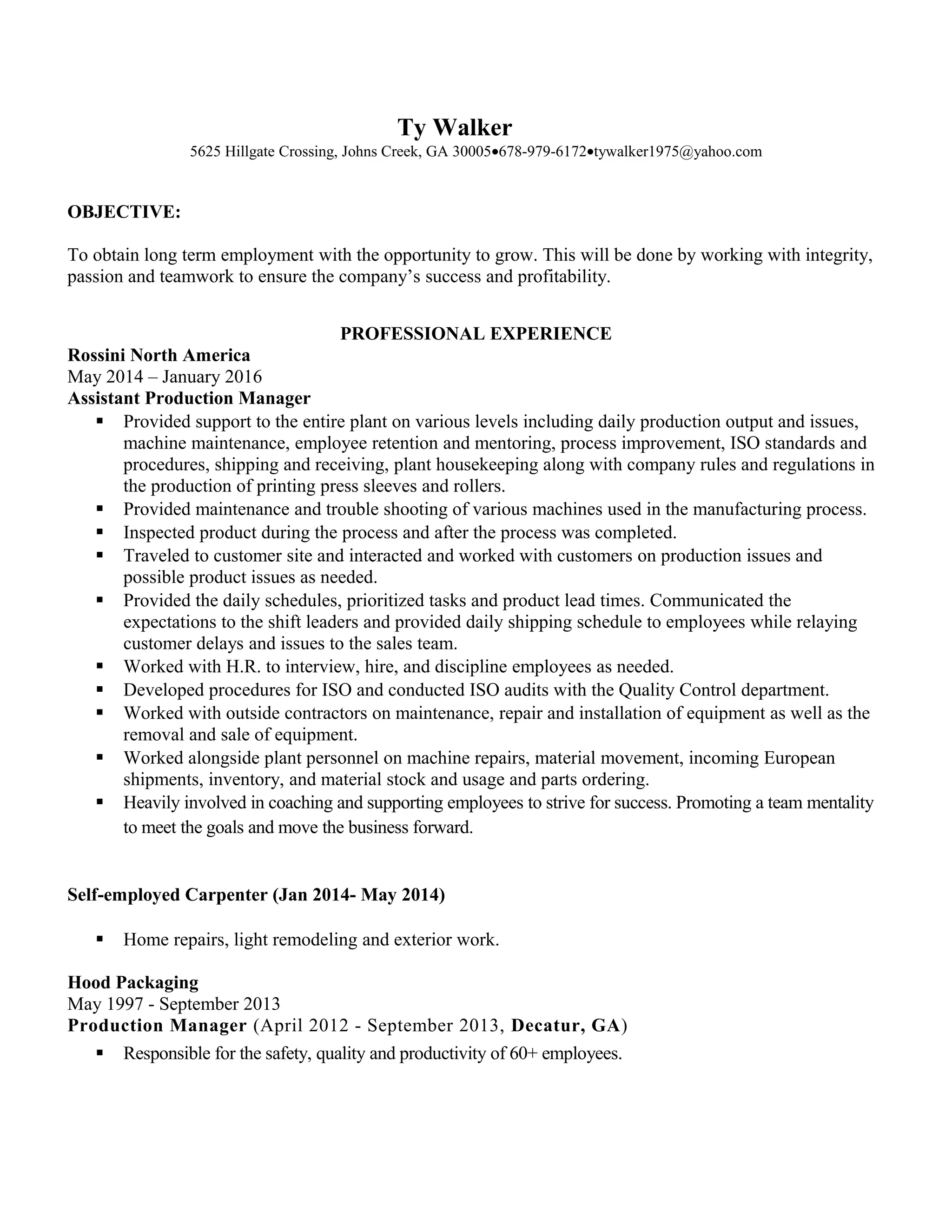

Ty Walker has over 20 years of experience in production management and operations in the printing and flexible packaging industries. He has a proven track record of improving safety, quality, and productivity while reducing waste. His experience includes overseeing production, training employees, implementing processes, conducting audits, and ensuring regulatory compliance. Walker seeks a long-term position where he can contribute to a company's success through integrity, passion, and teamwork.