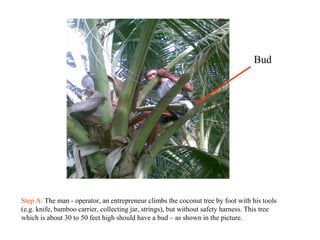

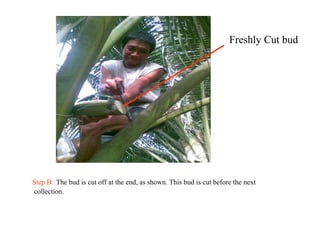

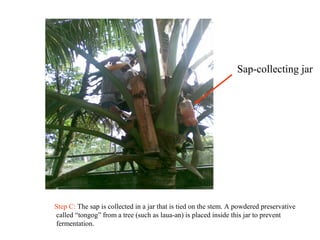

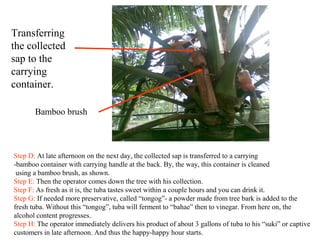

Tuba is a wine made from coconut sap in the Philippines. The process begins with a farmer climbing coconut trees to cut off young coconut buds. He collects the sap that flows from the buds in jars attached to the tree. The next day, he transfers the collected sap to bamboo containers for transport and delivery to customers. If not preserved, the sap will ferment over time, increasing in alcohol content and becoming vinegar. Within a couple hours of collection, the fresh tuba can be drunk as it is sweet, providing a product the farmer can sell to loyal customers each afternoon.