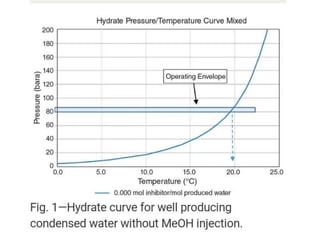

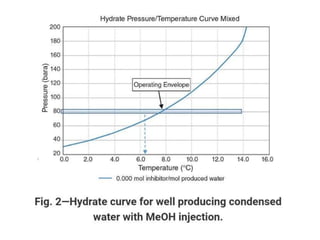

Transient modeling was used to address hydrate formation issues in pipelines connecting wells to processing facilities in Kuwait's North Kuwait Jurassic fields. The modeling aimed to optimize methanol injection to prevent hydrate plugging while accounting for different well fluid compositions and transient flow conditions. Wells were categorized based on their water salinity and modeled individually. The transient modeling provided hydrate and surge advisors to monitor temperature margins and predict slug flow issues better than steady-state models. The solution was expanded to additional wells to minimize production losses from hydrates and pipeline corrosion.