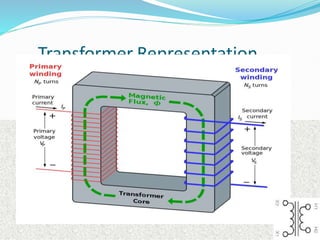

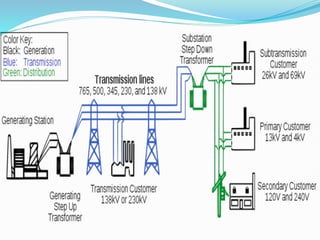

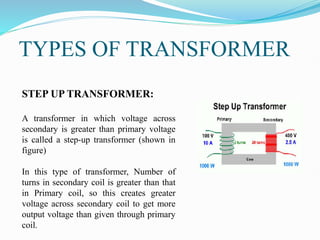

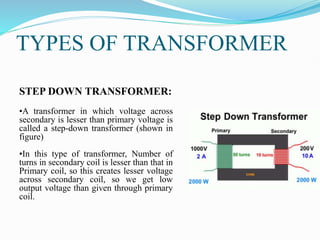

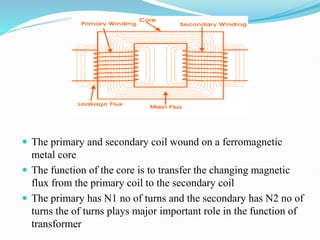

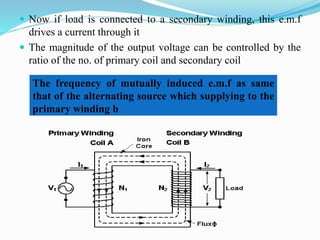

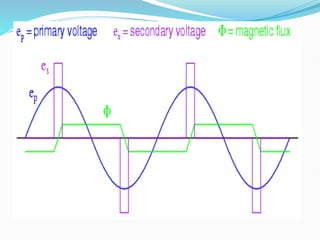

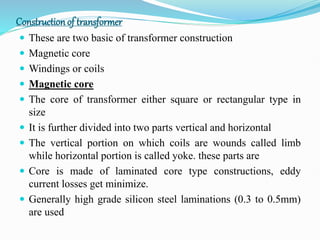

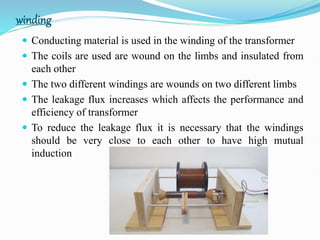

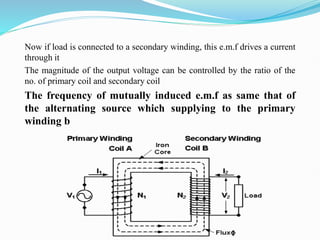

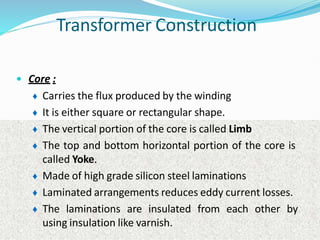

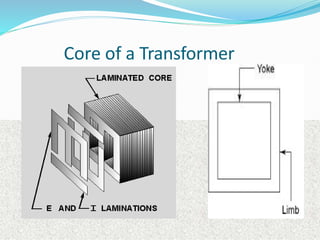

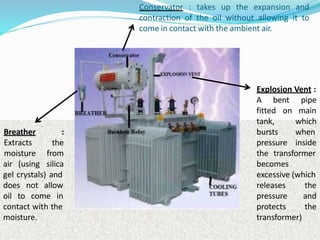

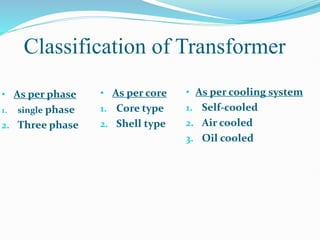

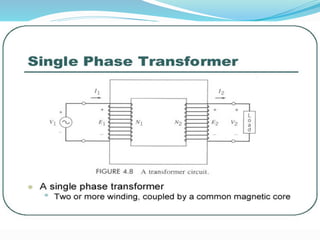

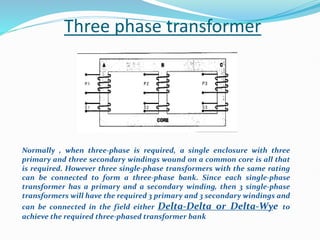

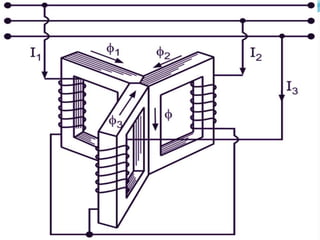

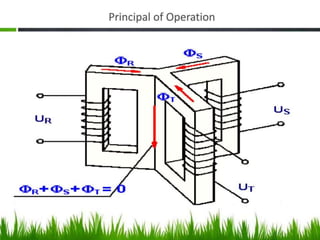

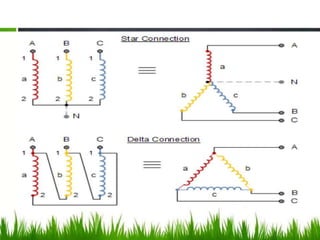

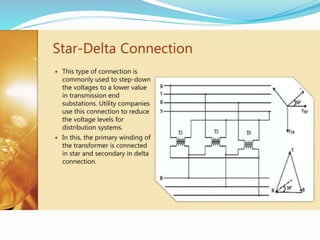

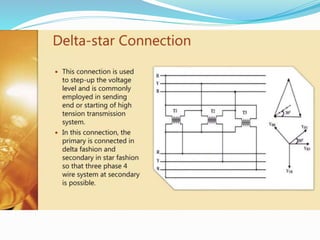

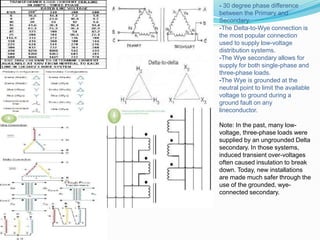

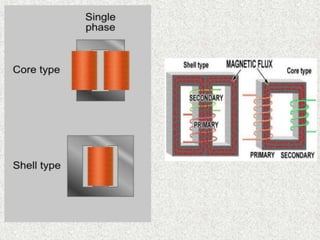

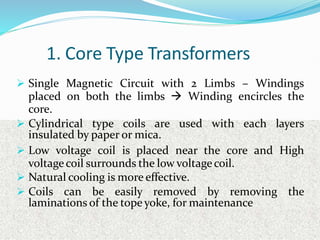

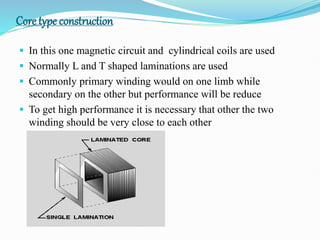

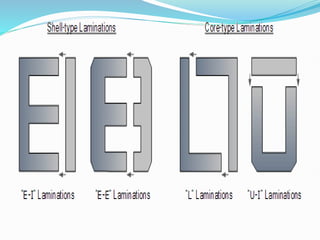

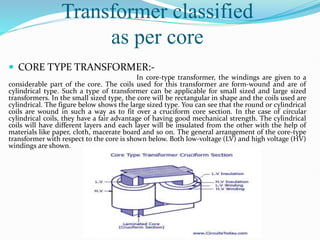

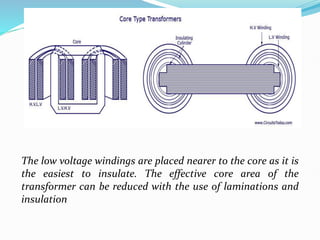

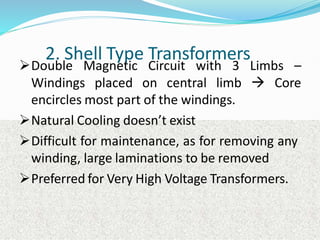

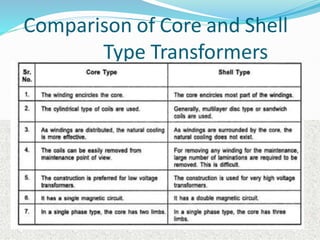

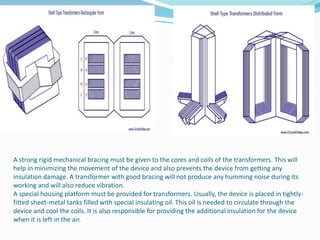

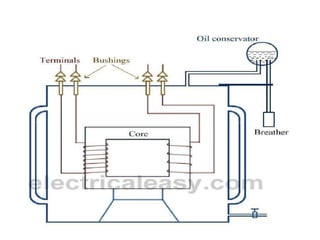

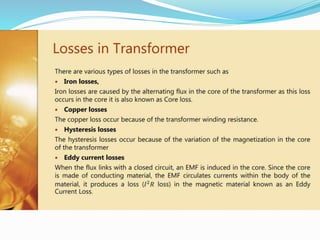

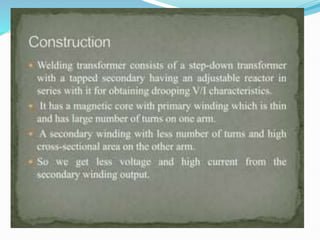

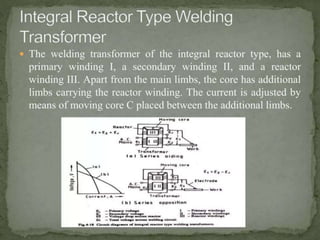

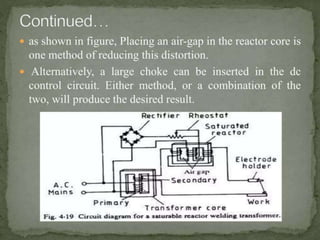

The document provides an extensive overview of transformers, detailing their definition, construction, working principles, types, and applications. It explains how transformers operate on the principle of mutual induction to change voltage and current levels without changing frequency, with descriptions of step-up and step-down transformers. Additionally, it covers various transformer classifications based on phase, core type, cooling systems, and specialized designs for maritime applications.