Embed presentation

Download as PDF, PPTX

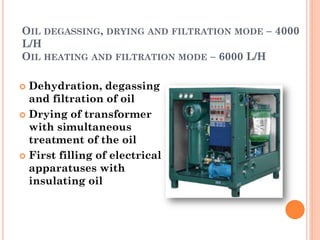

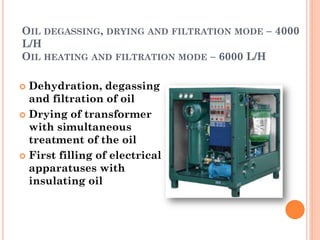

The document details various transformer oil purification systems with capacities ranging from 160 to 6000 liters per hour, highlighting their benefits such as degassing, dehydration, and particle removal, which extend oil life and reduce equipment downtime. It includes specific models and options for installation, like a roadworthy trailer. Contact information for sales inquiries is also provided.