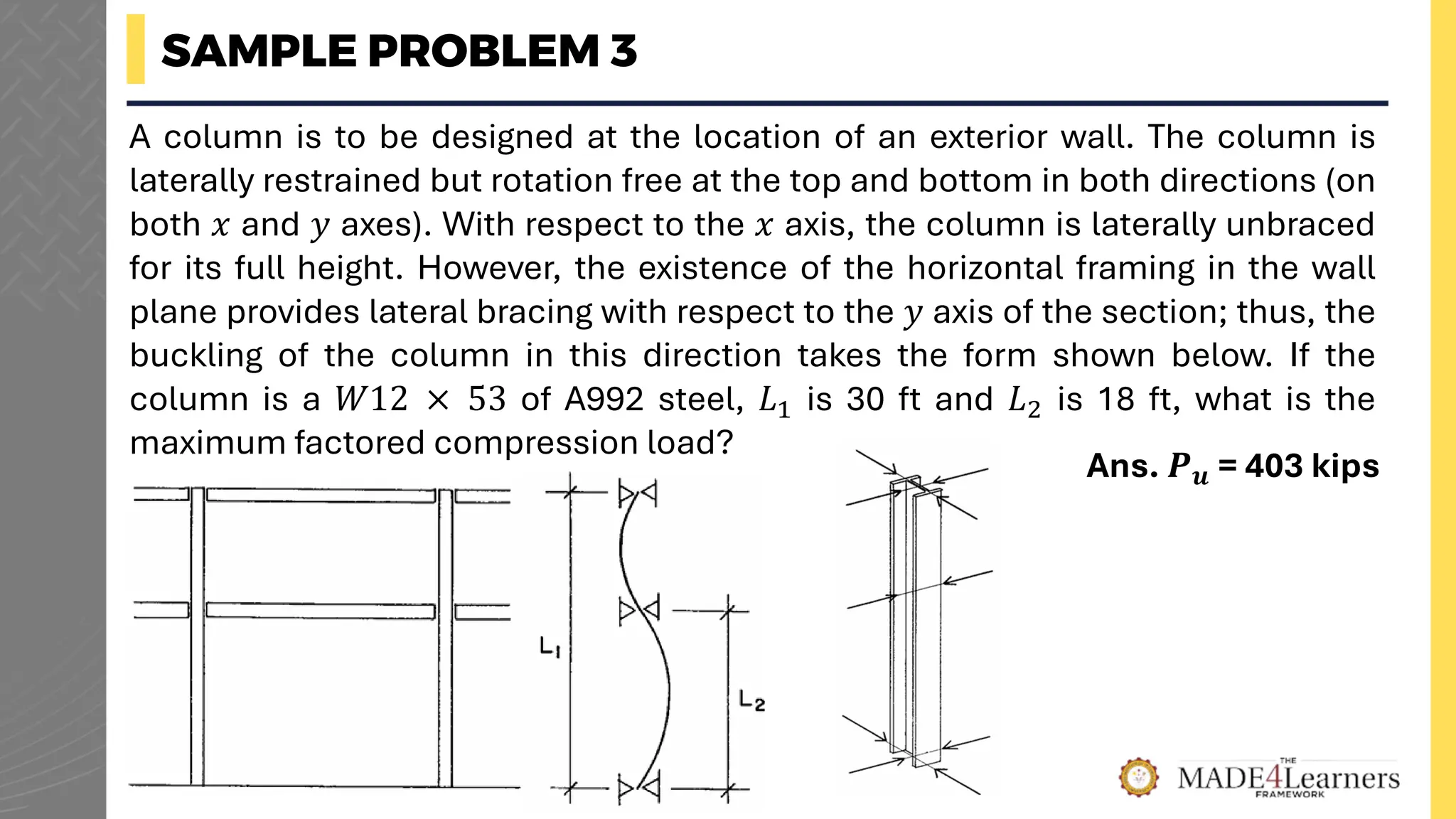

The document discusses compression members in structural engineering, particularly focusing on their behavior under axial loads and the resulting buckling phenomena. It details the critical buckling load derived from Euler's theory, including various calculations and assumptions necessary for the analysis. Additionally, it includes example problems illustrating the application of design standards and factors affecting the stability and strength of compression members in structures.