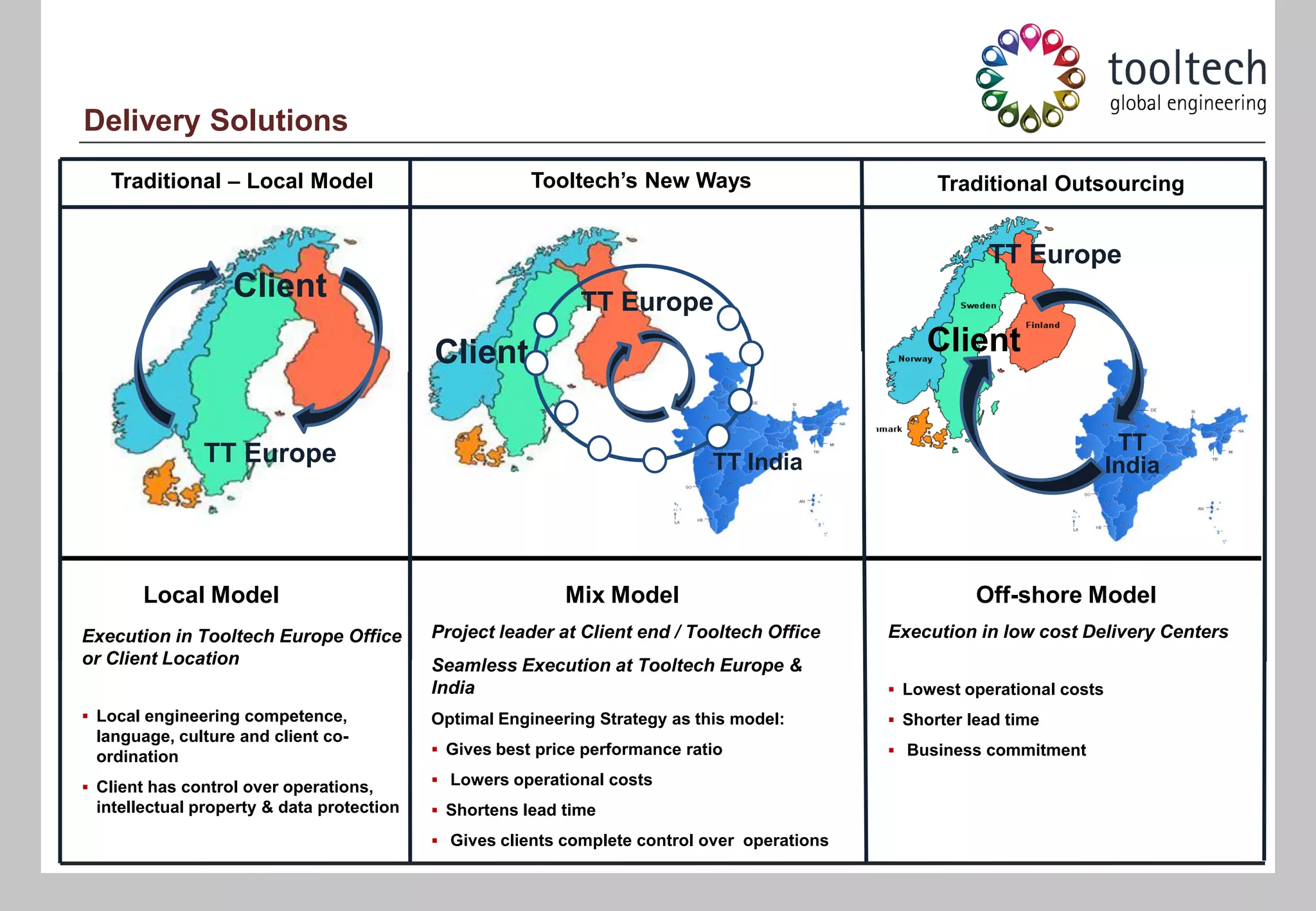

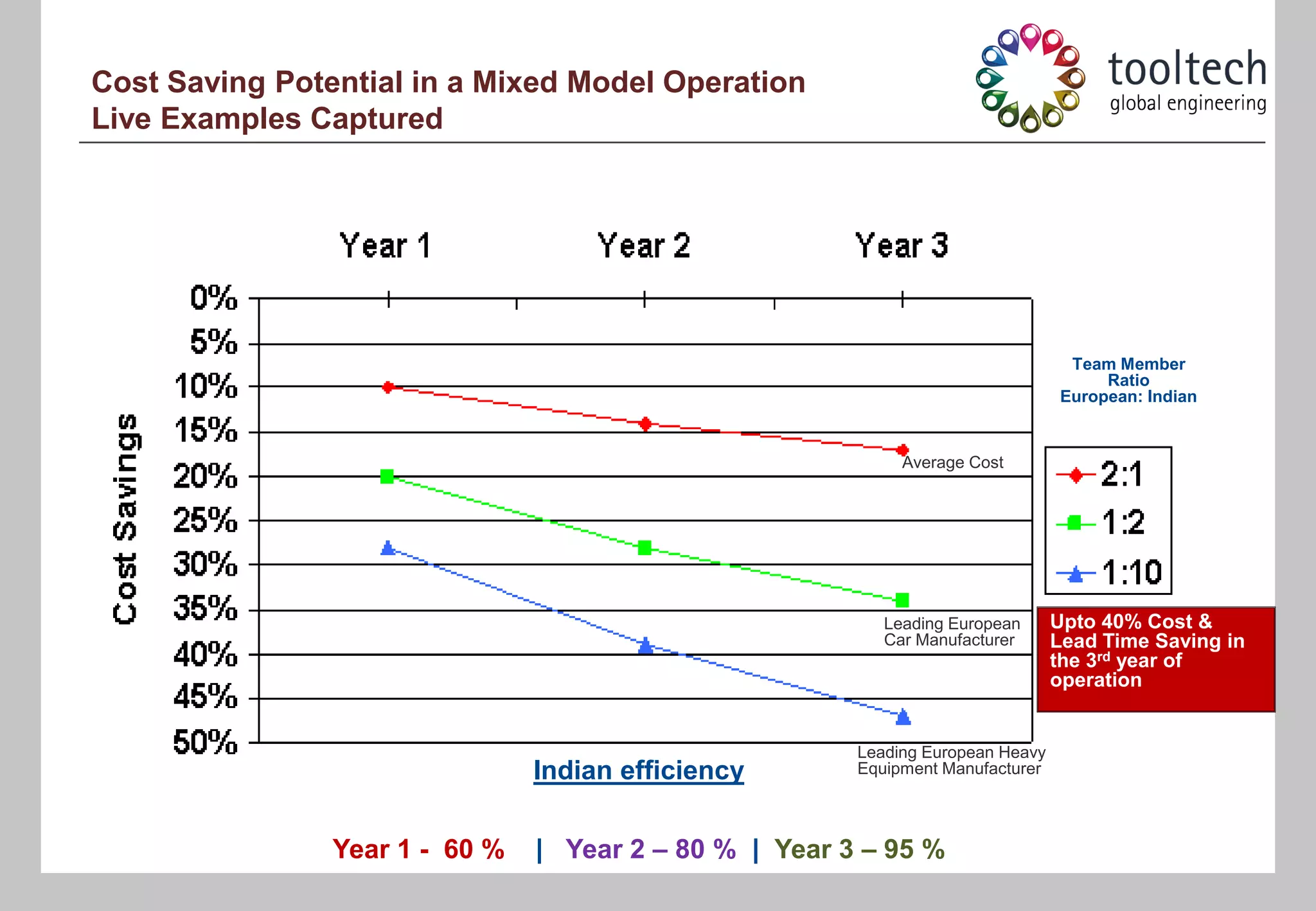

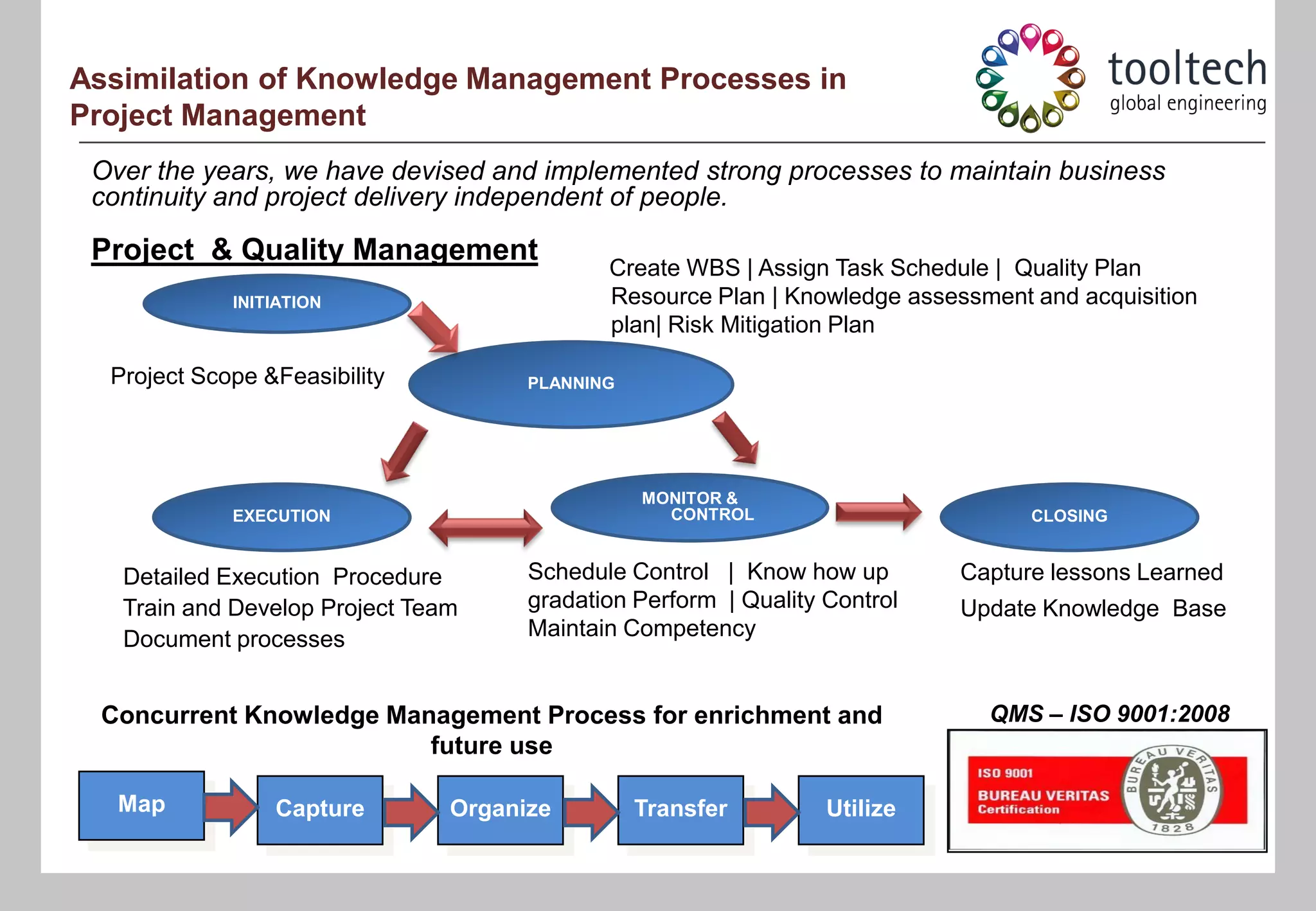

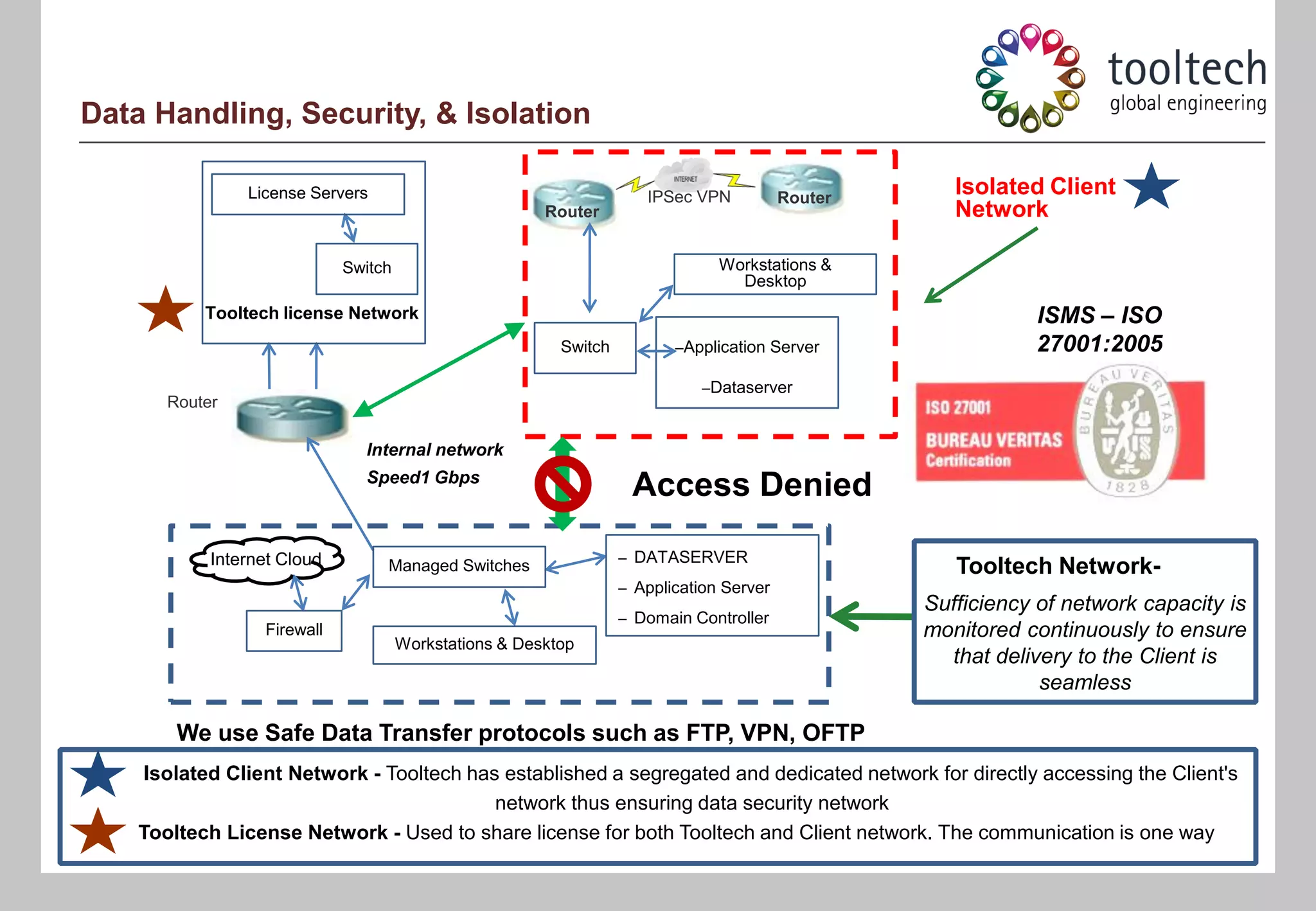

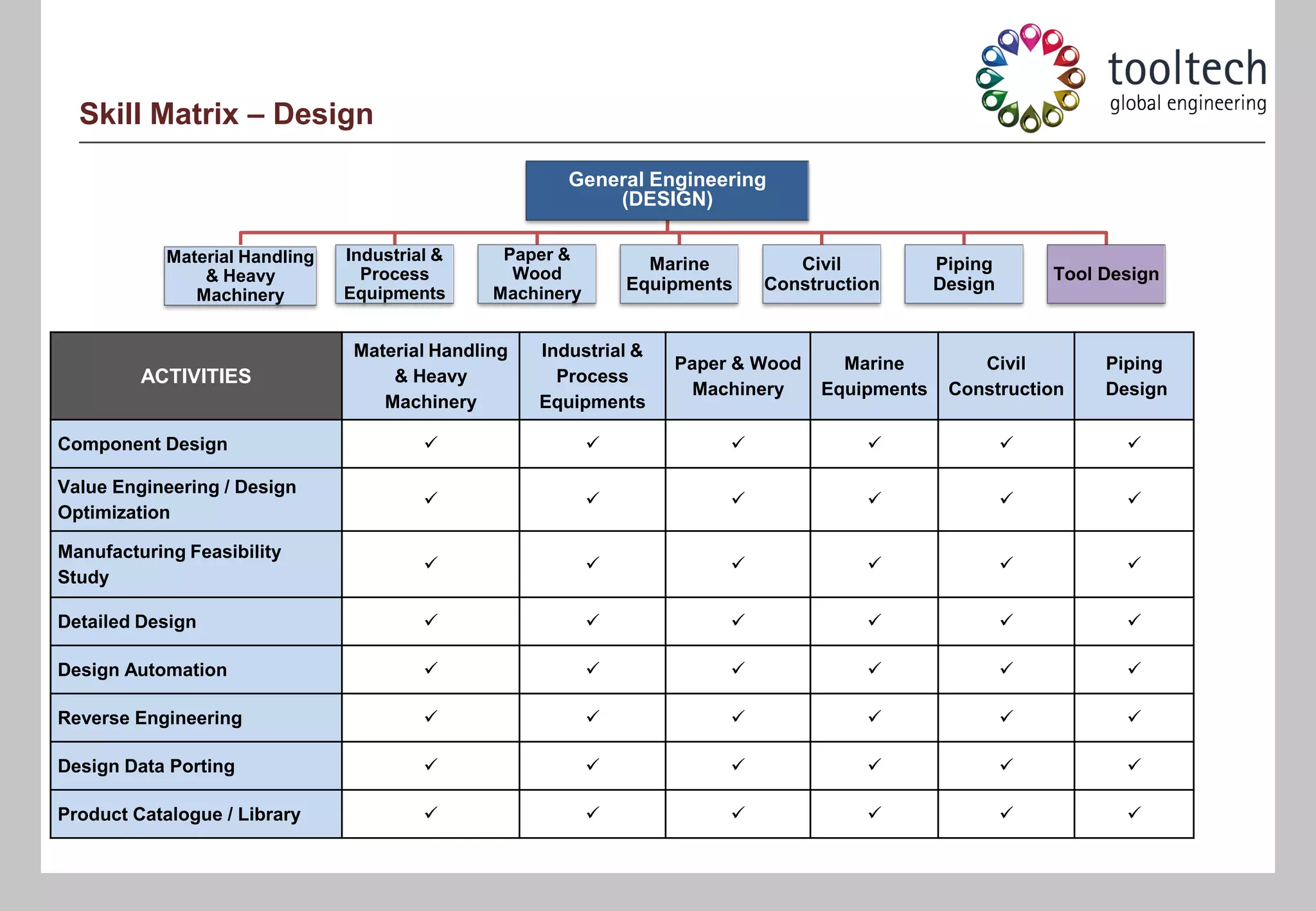

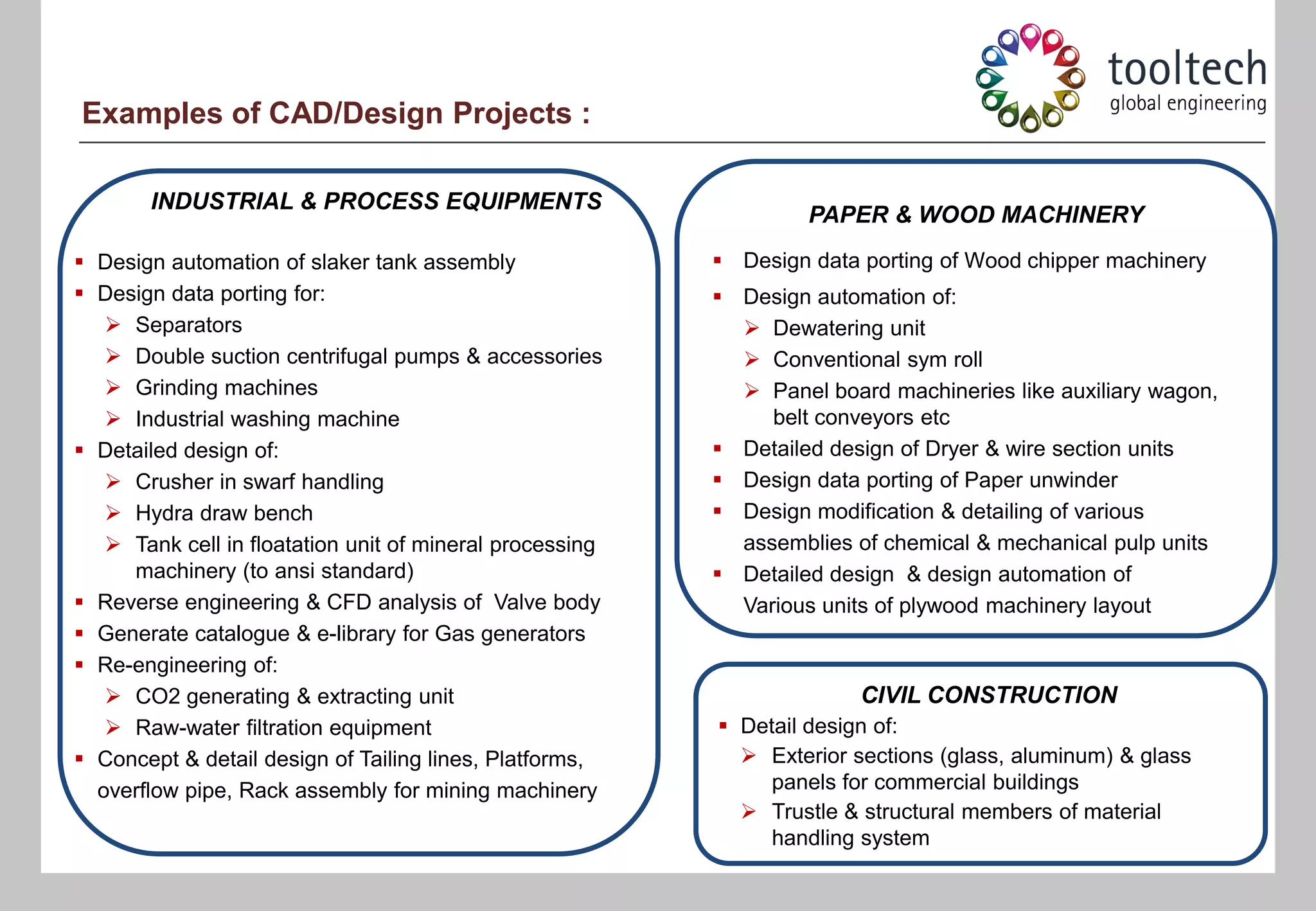

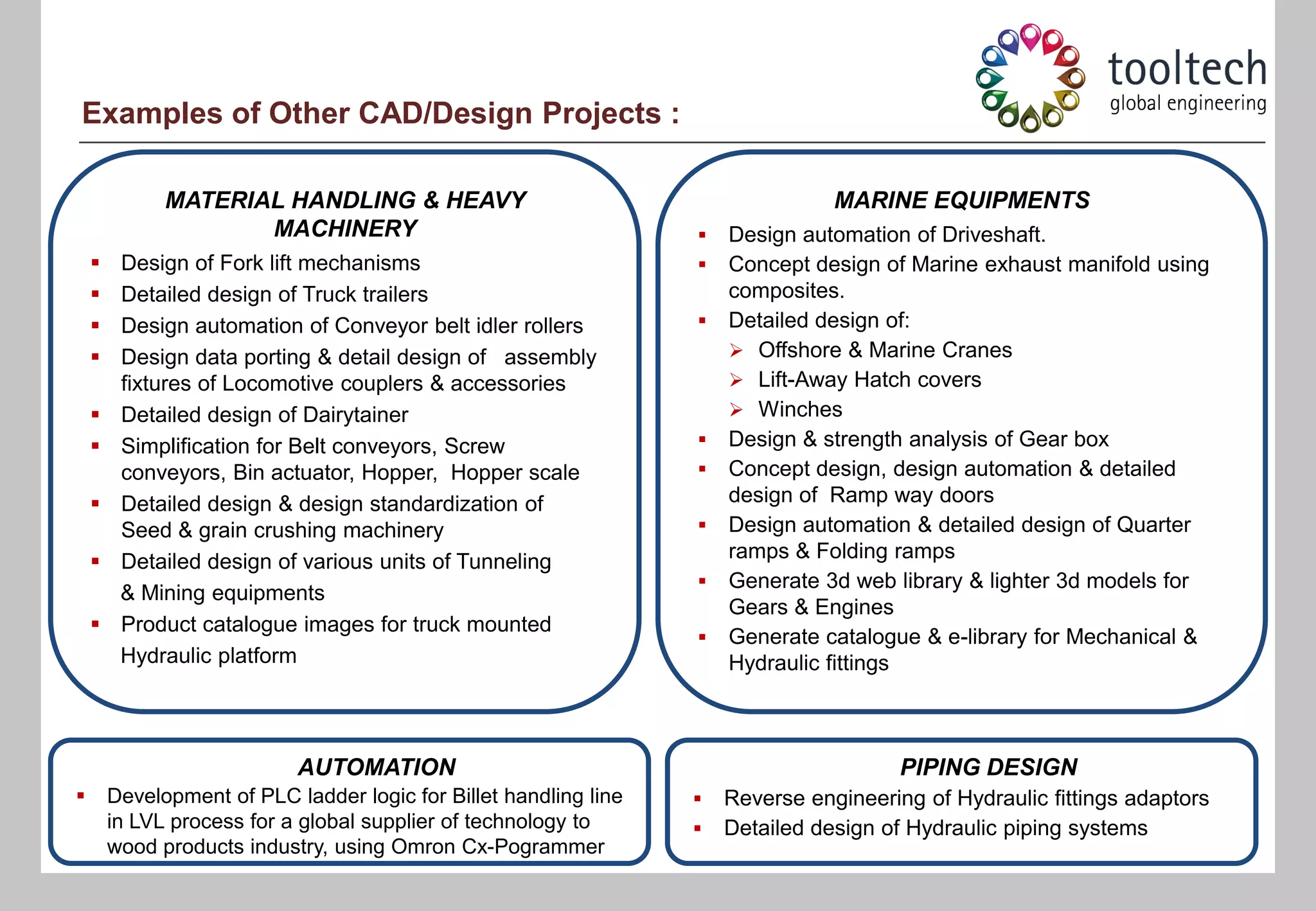

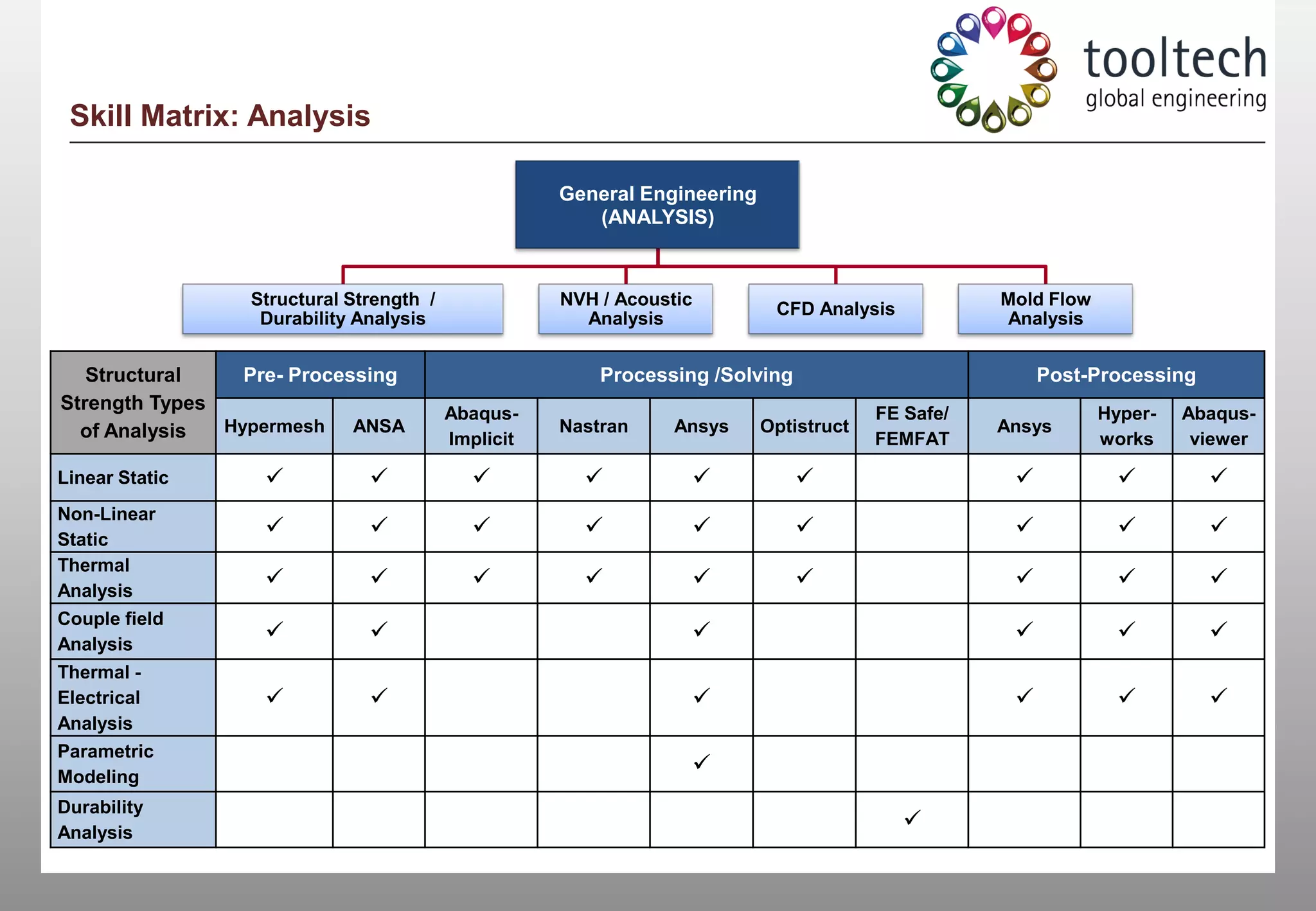

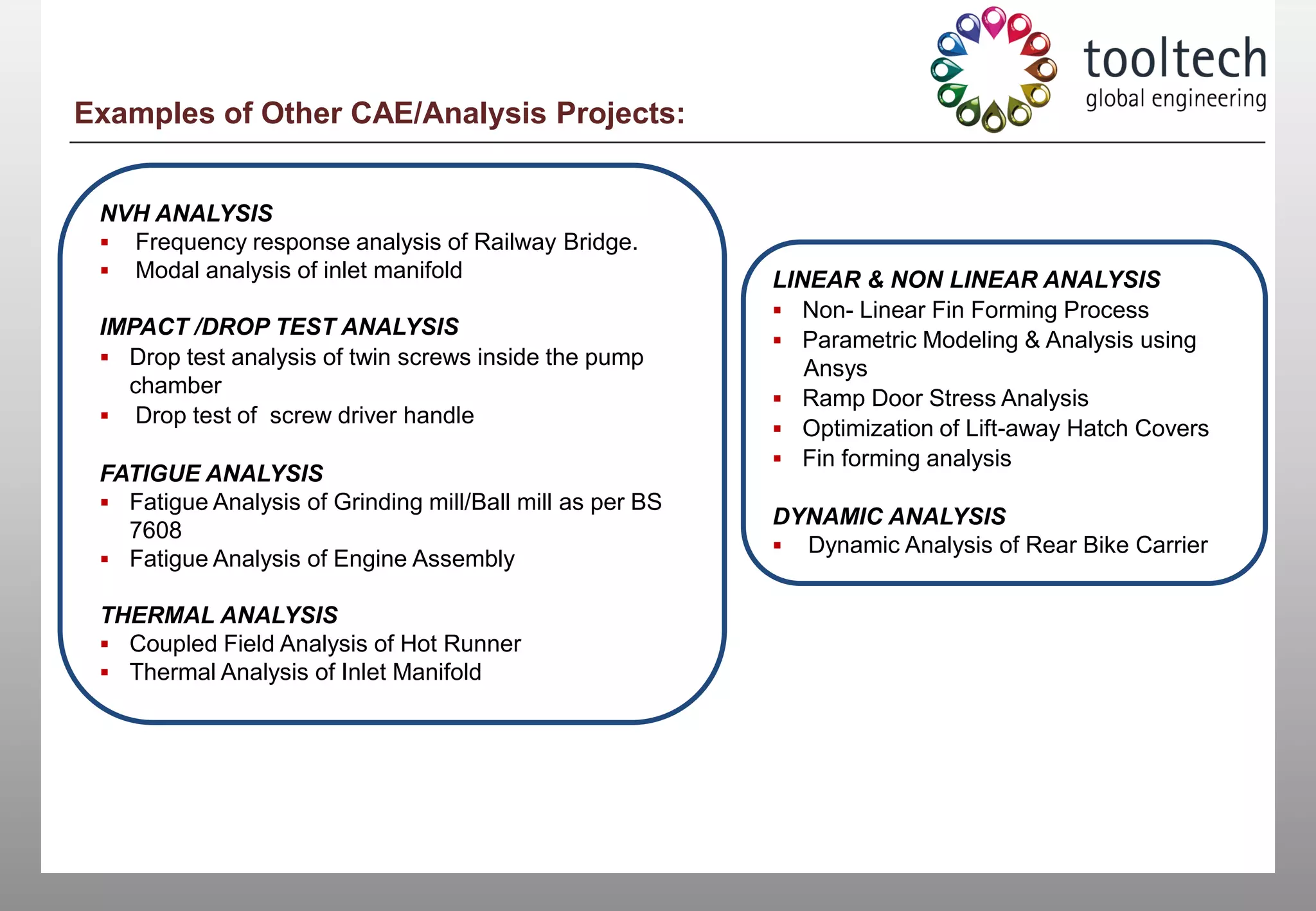

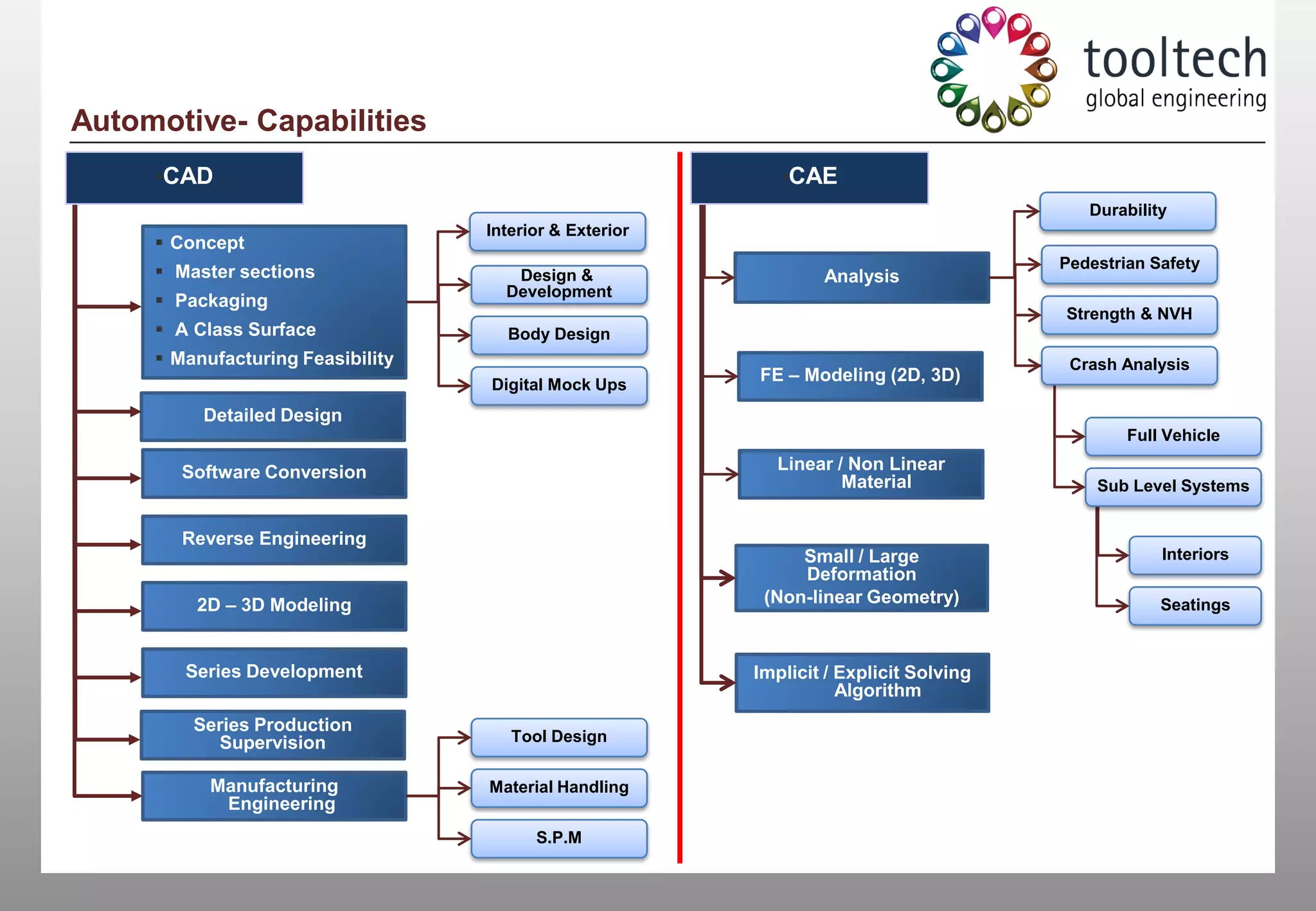

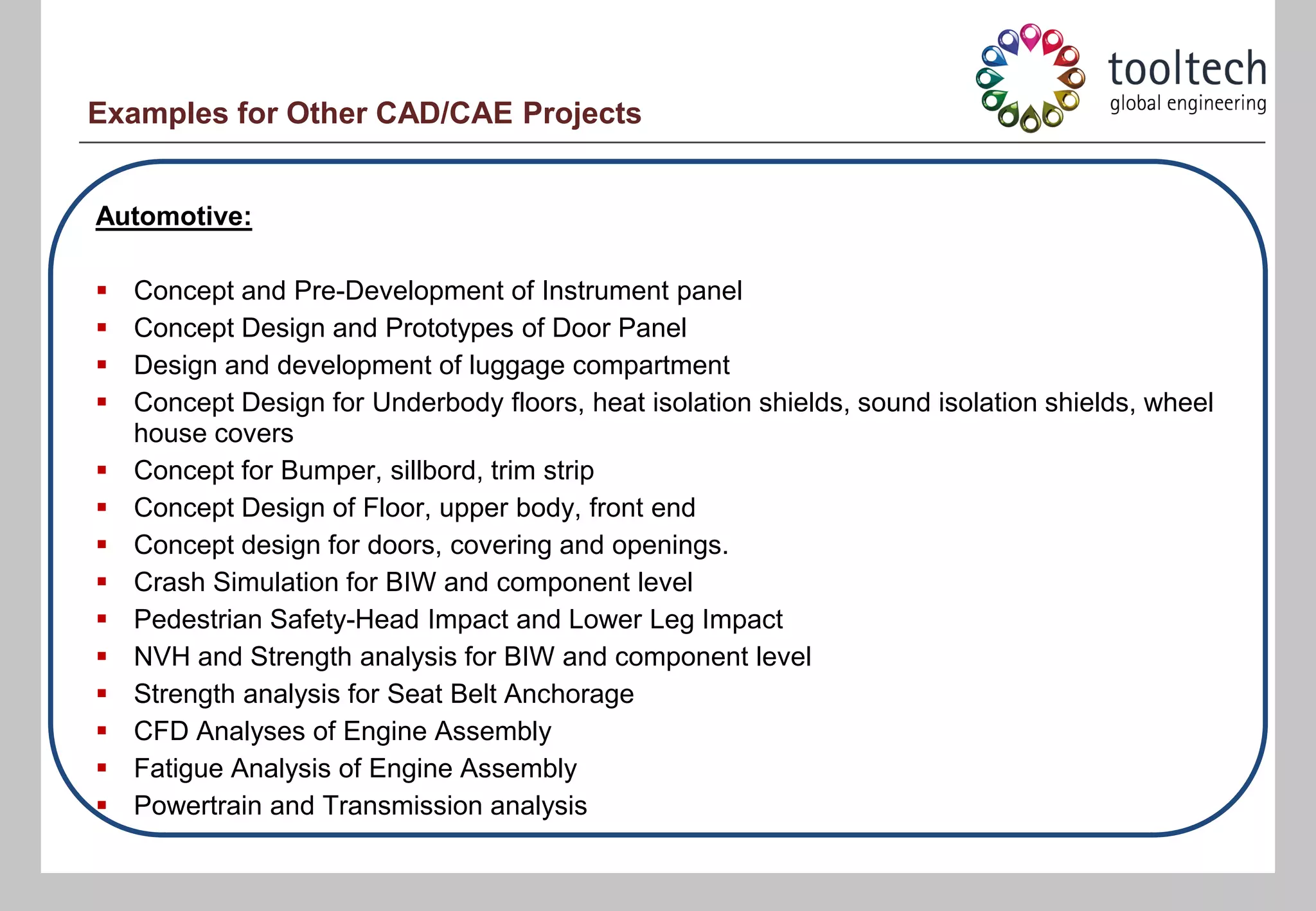

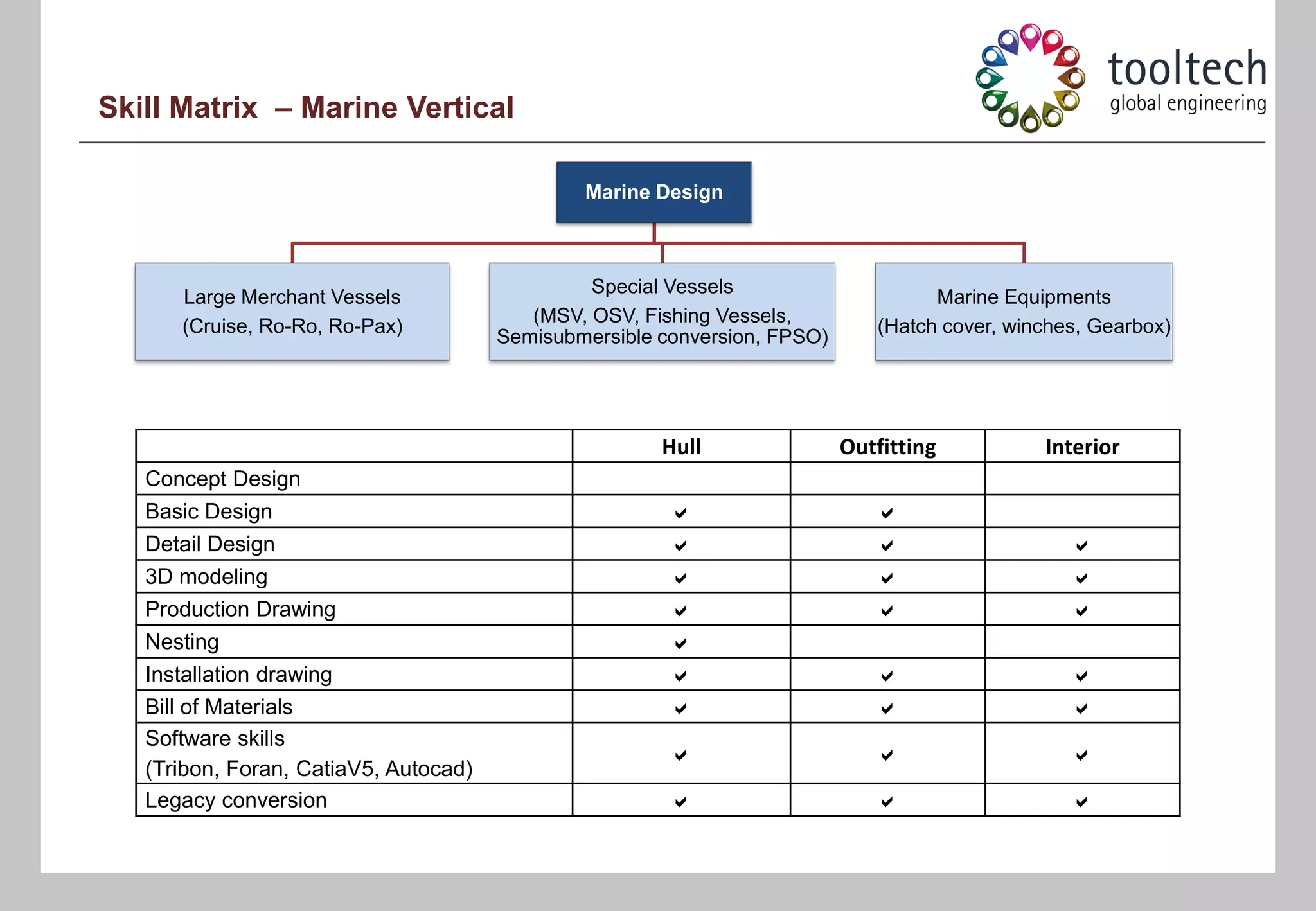

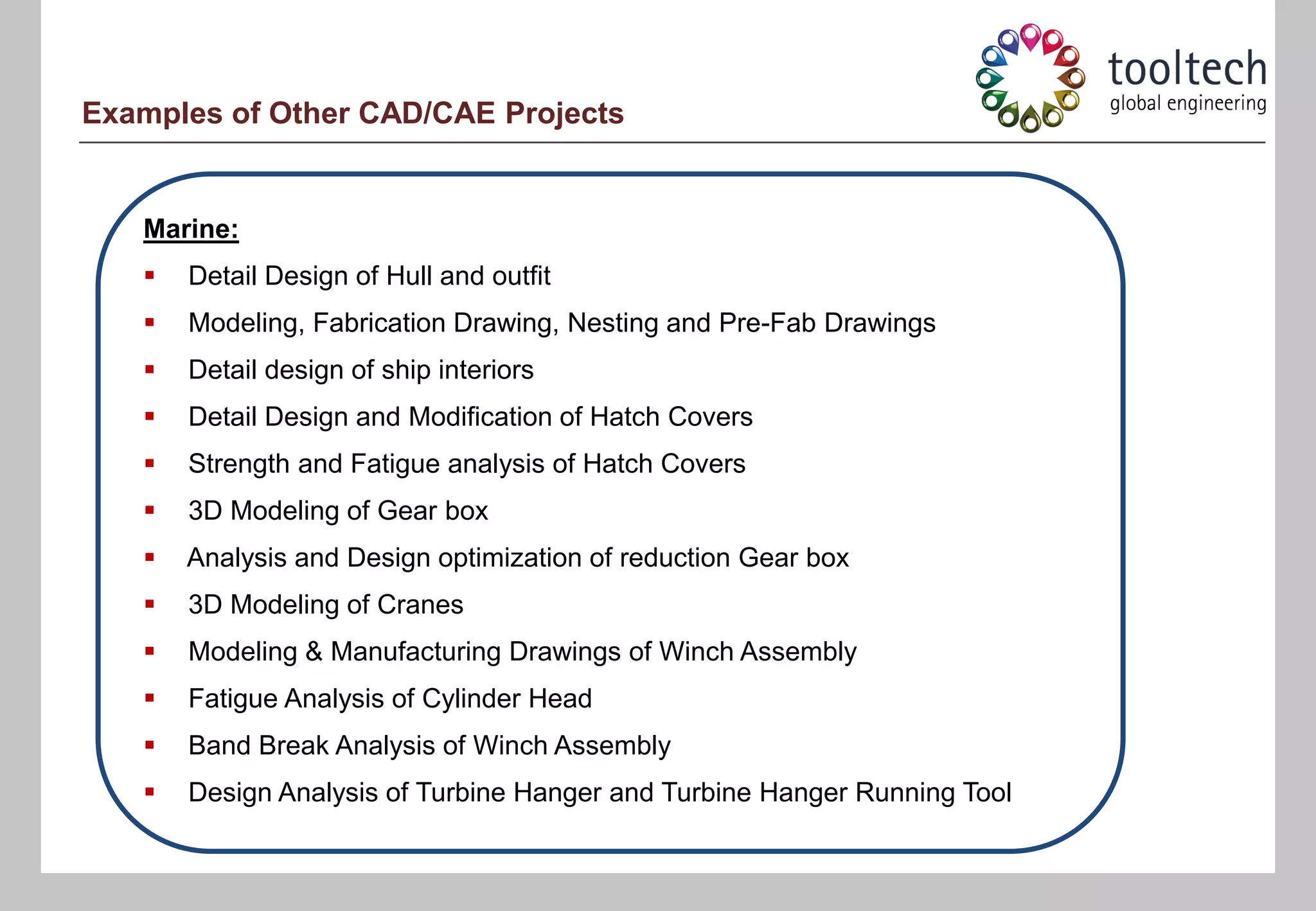

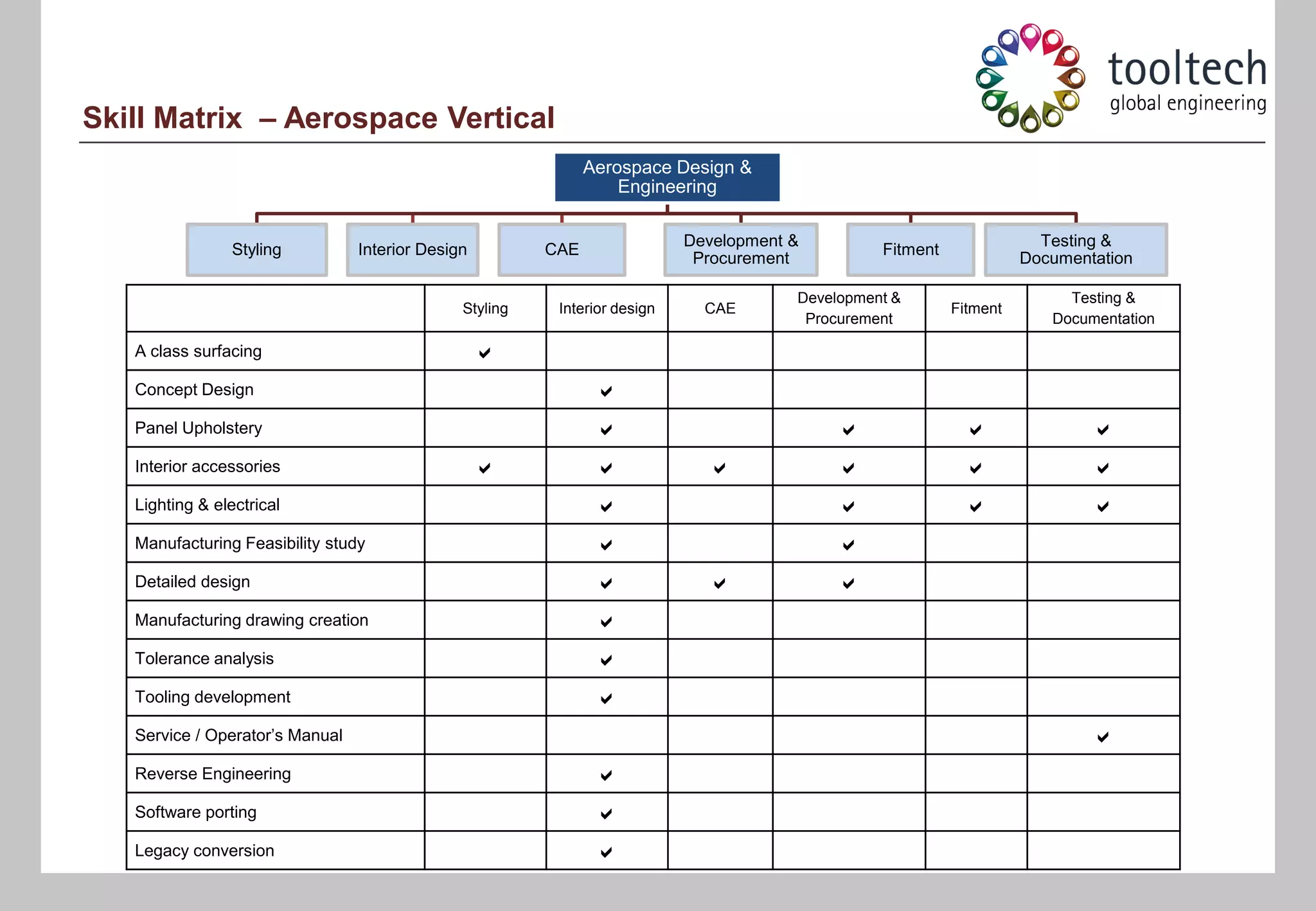

Tooltech is a provider of remote engineering design and simulation solutions across various sectors such as automotive, aerospace, and marine equipment. They utilize a pioneering mix model that combines European engineering expertise with Indian workforce efficiency, aiming to enhance competitiveness and reduce operational costs for clients. Tooltech offers comprehensive service capabilities including CAD and CAE solutions, while ensuring data security and quality management through adherence to ISO standards.