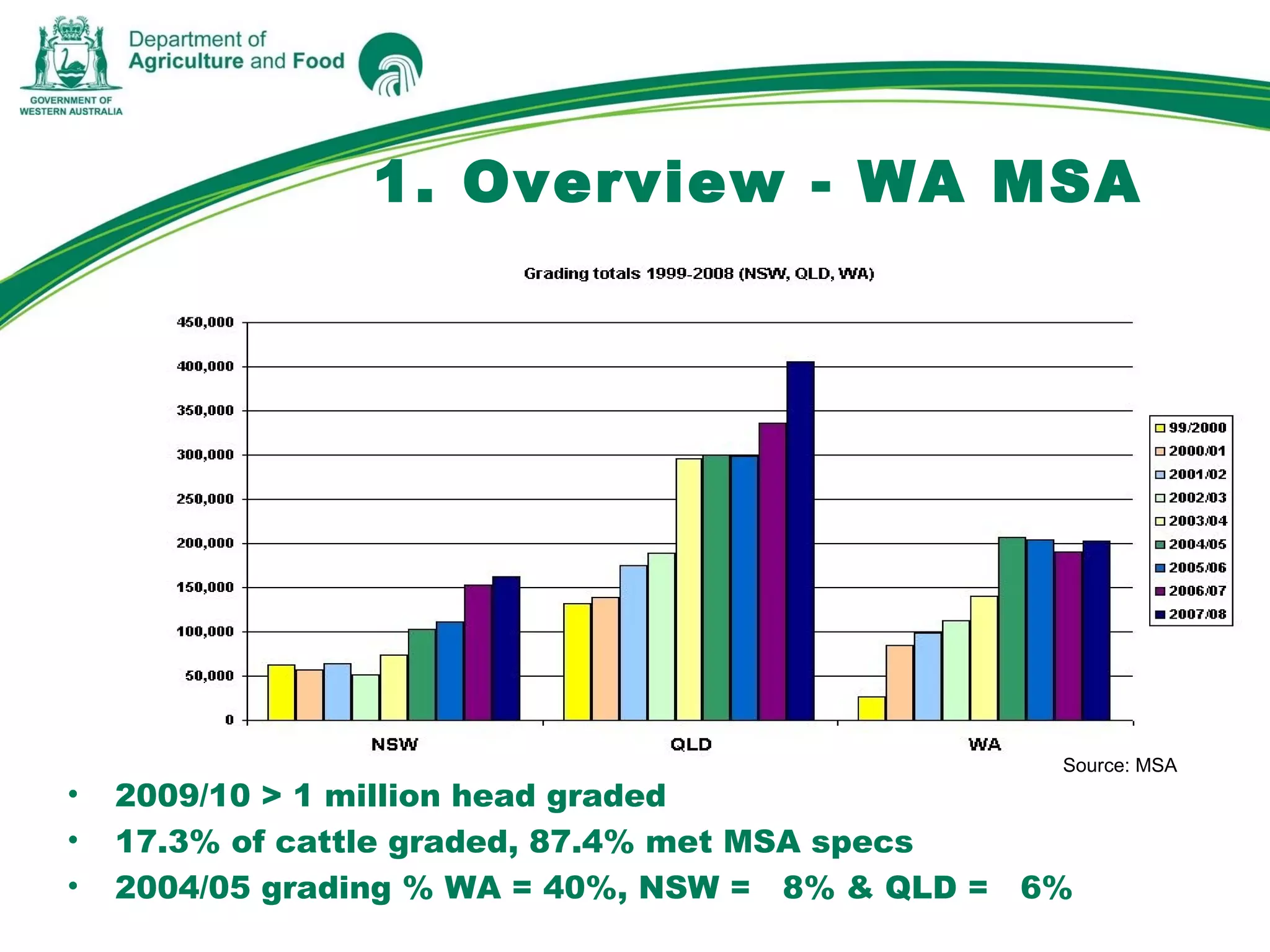

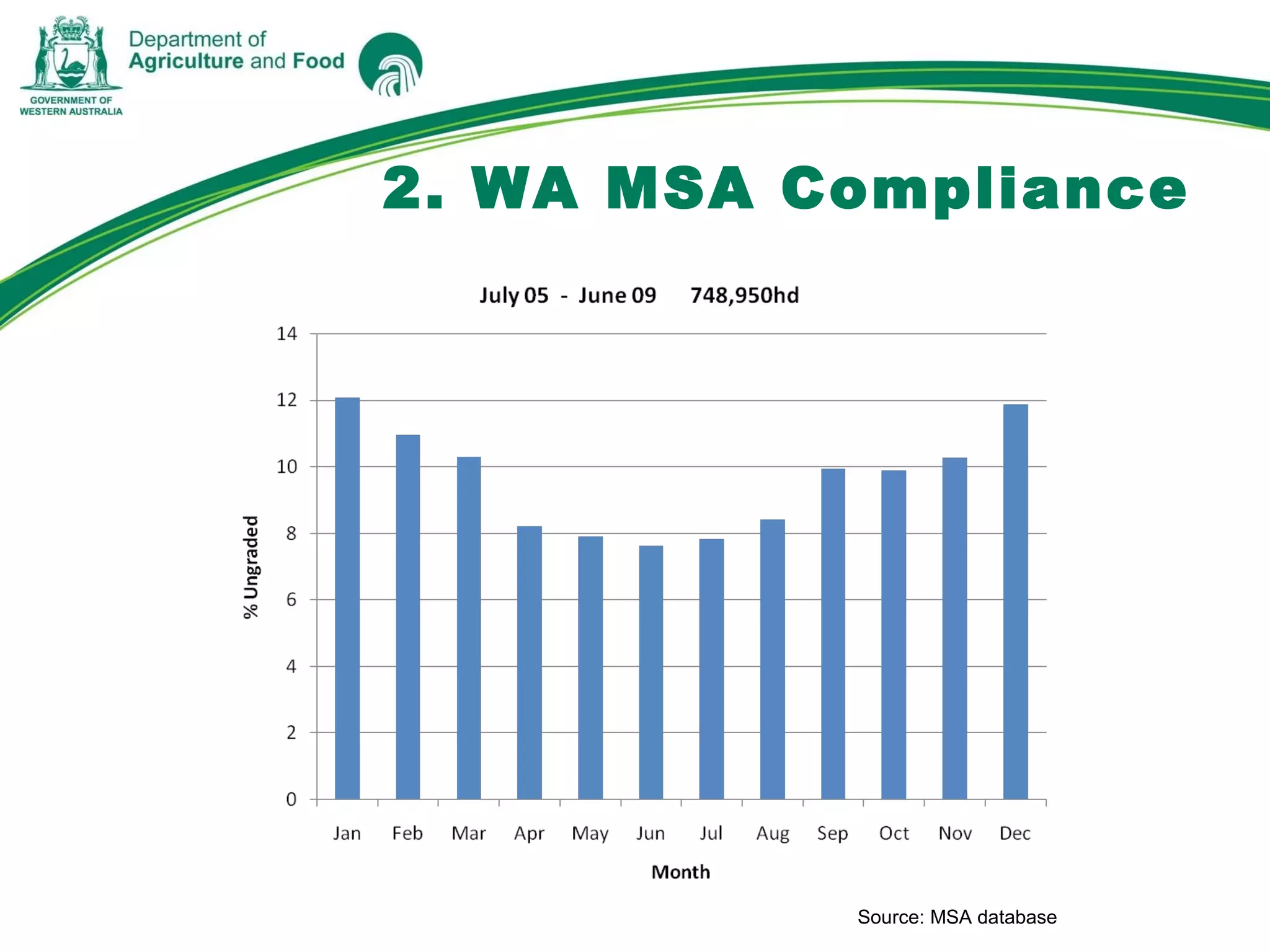

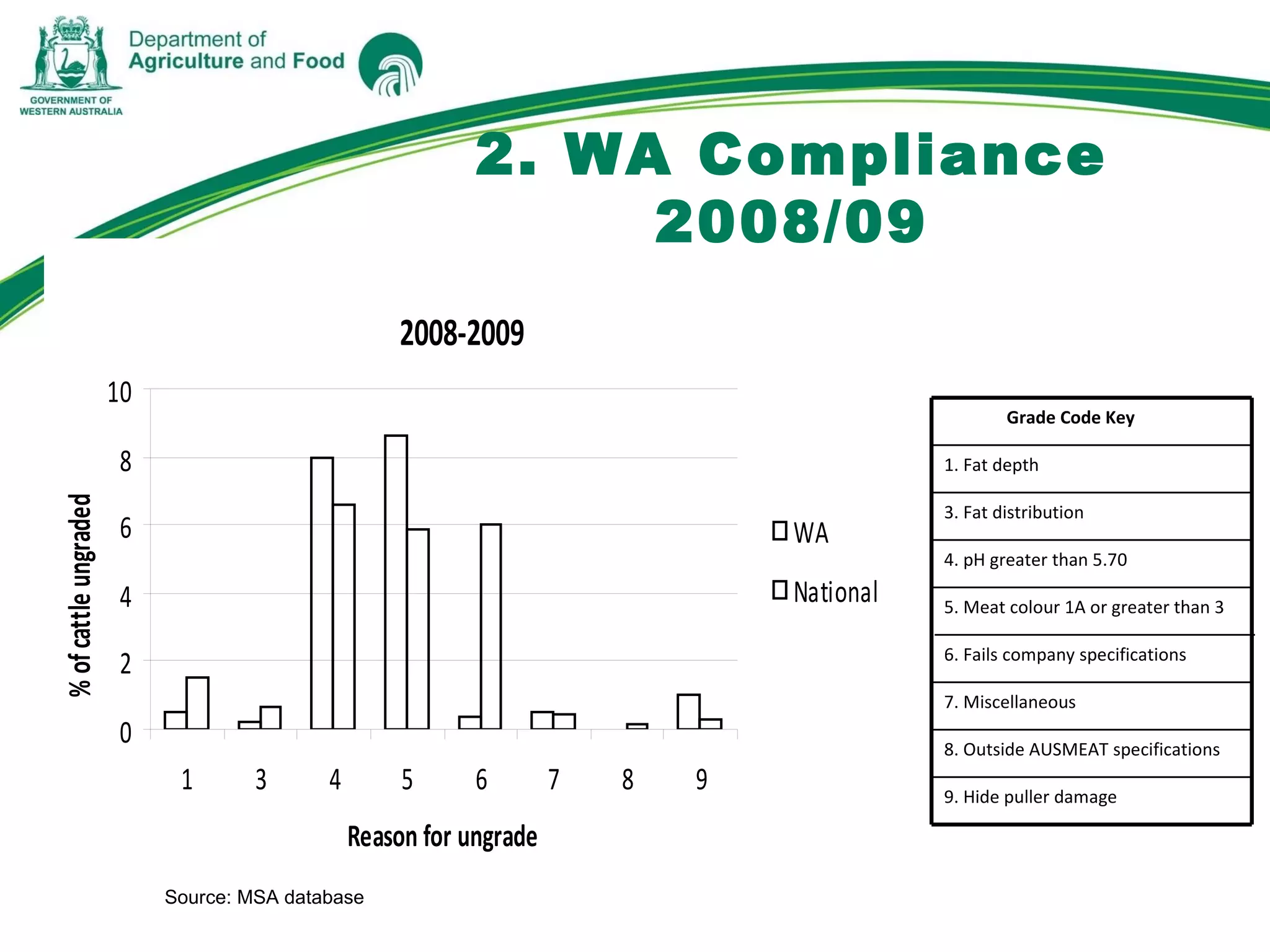

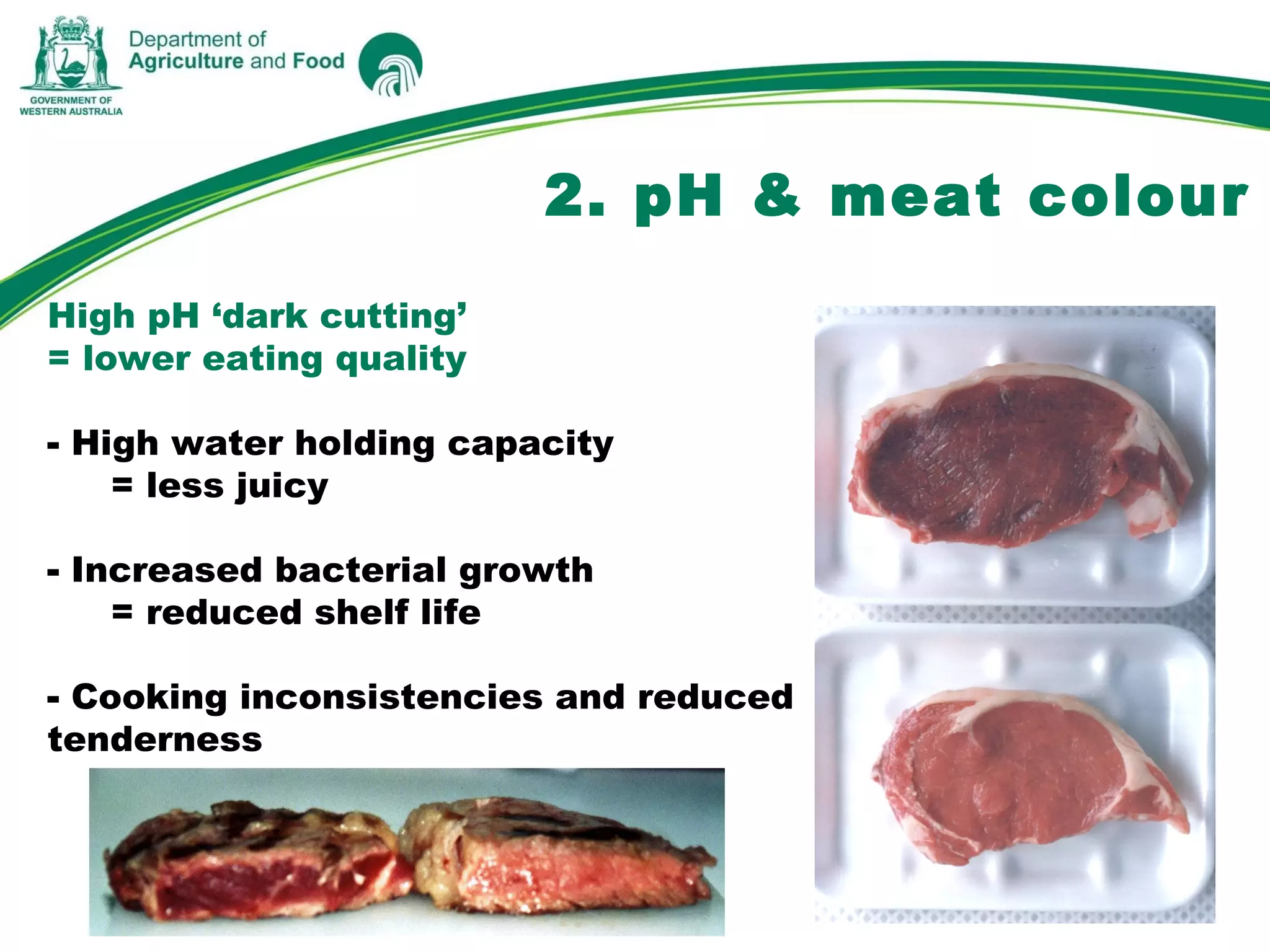

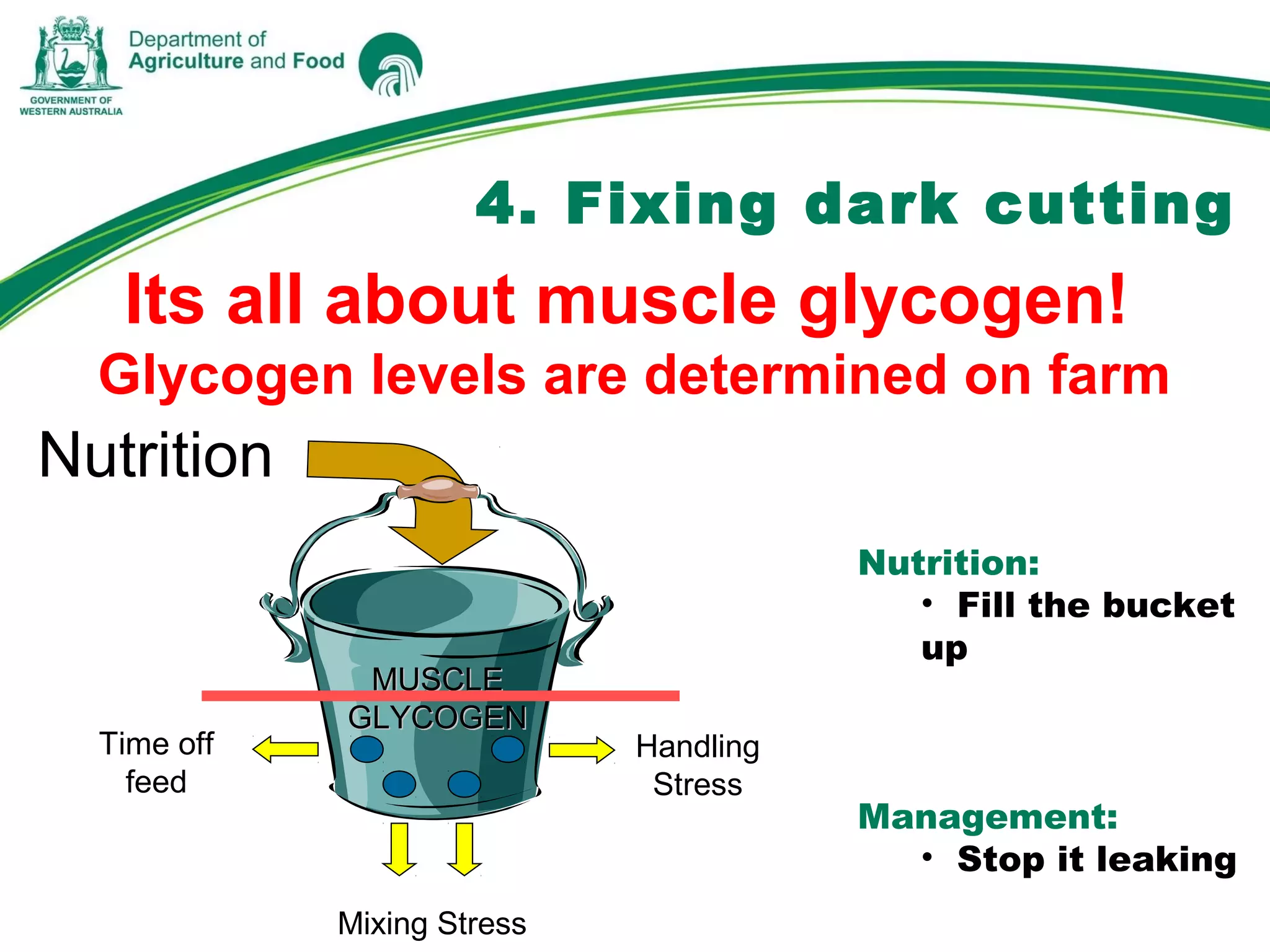

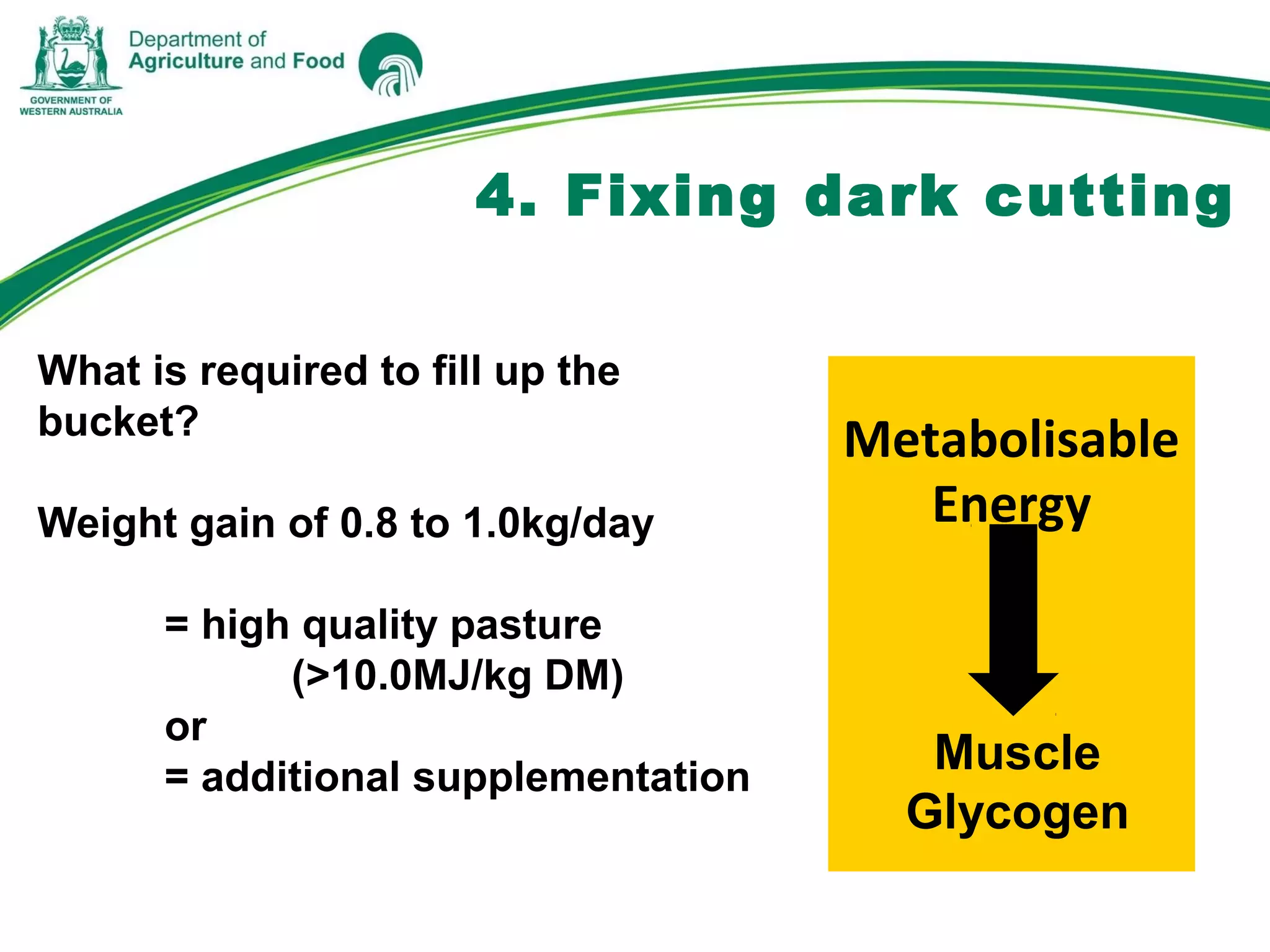

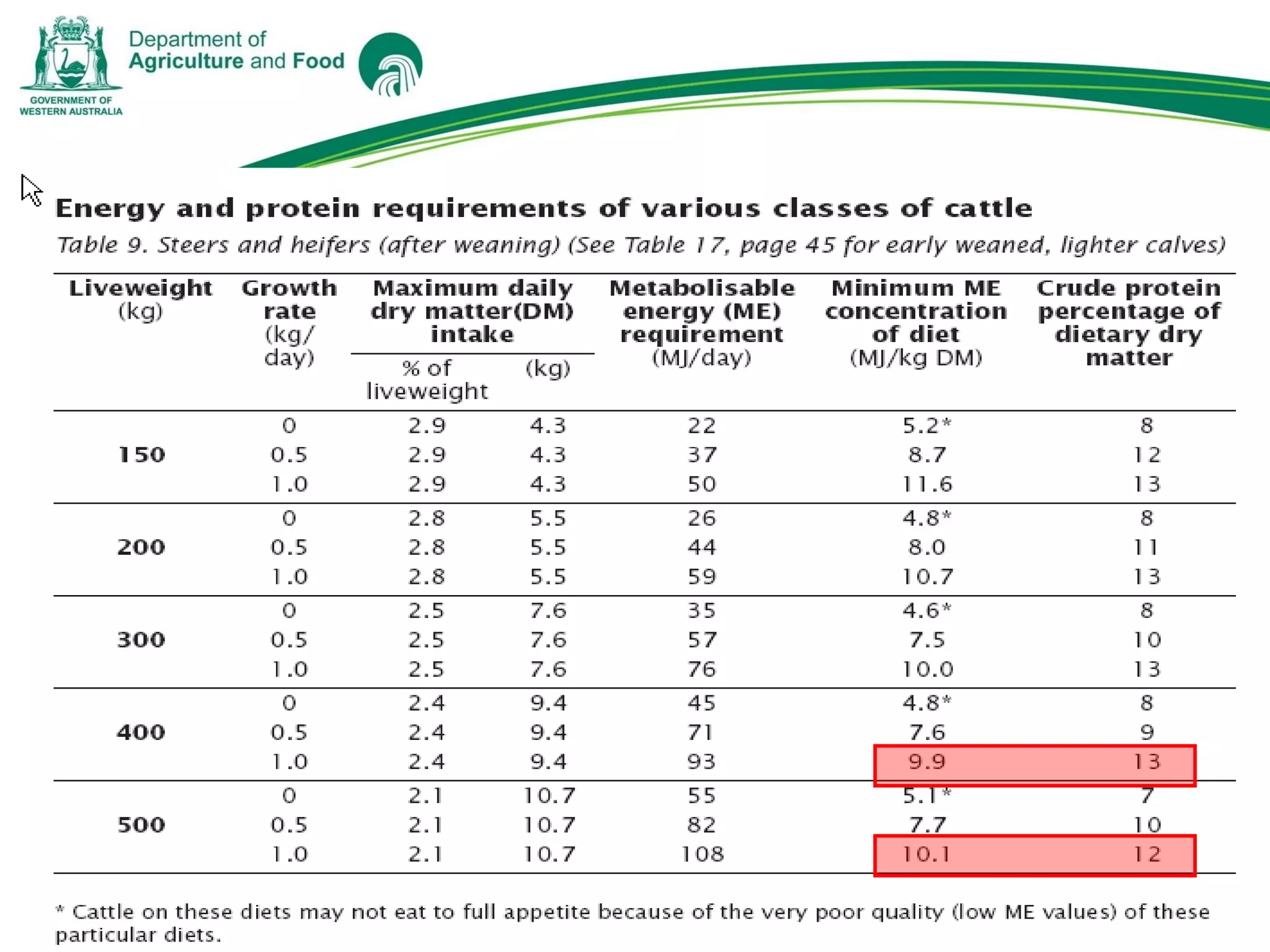

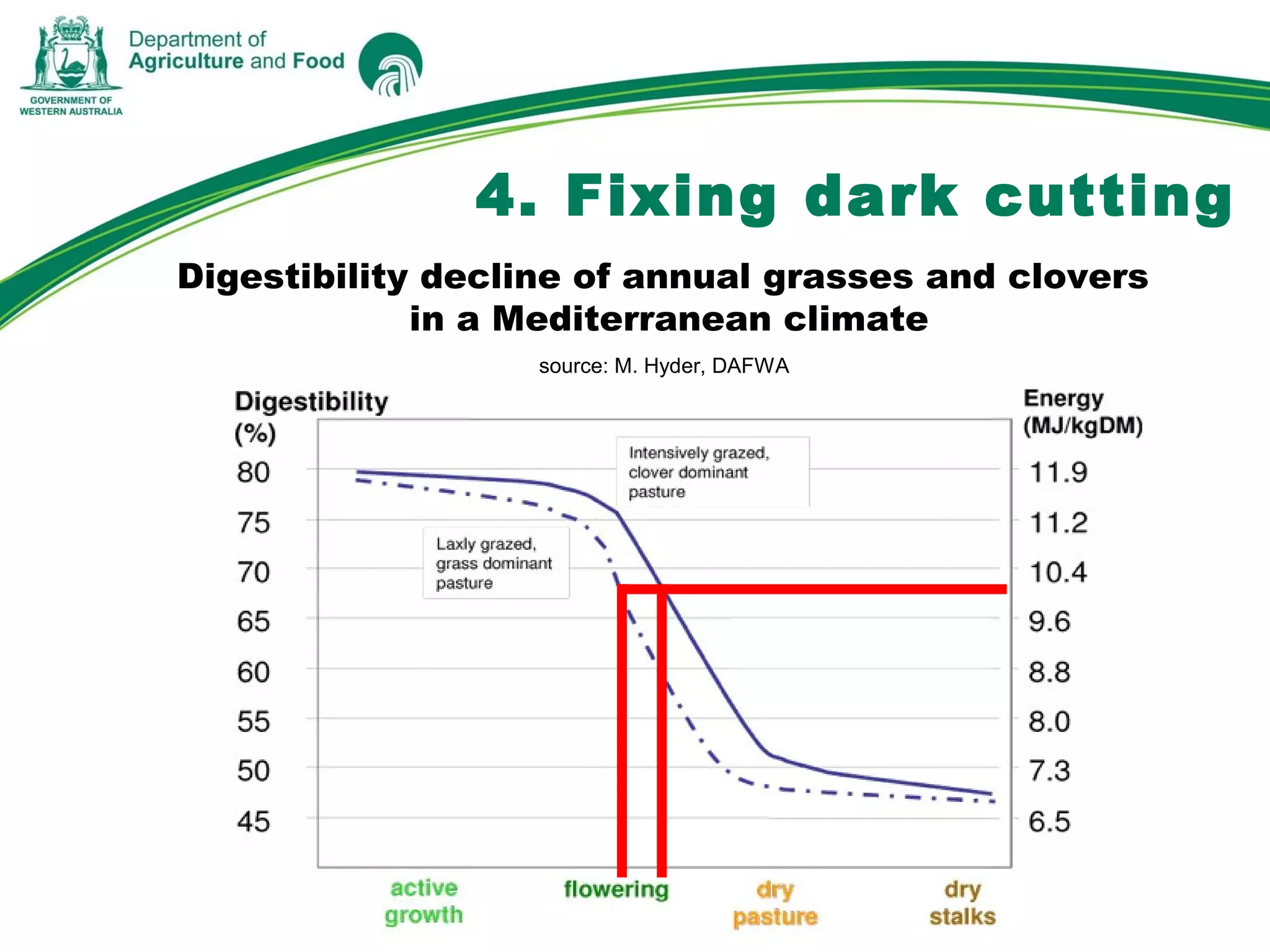

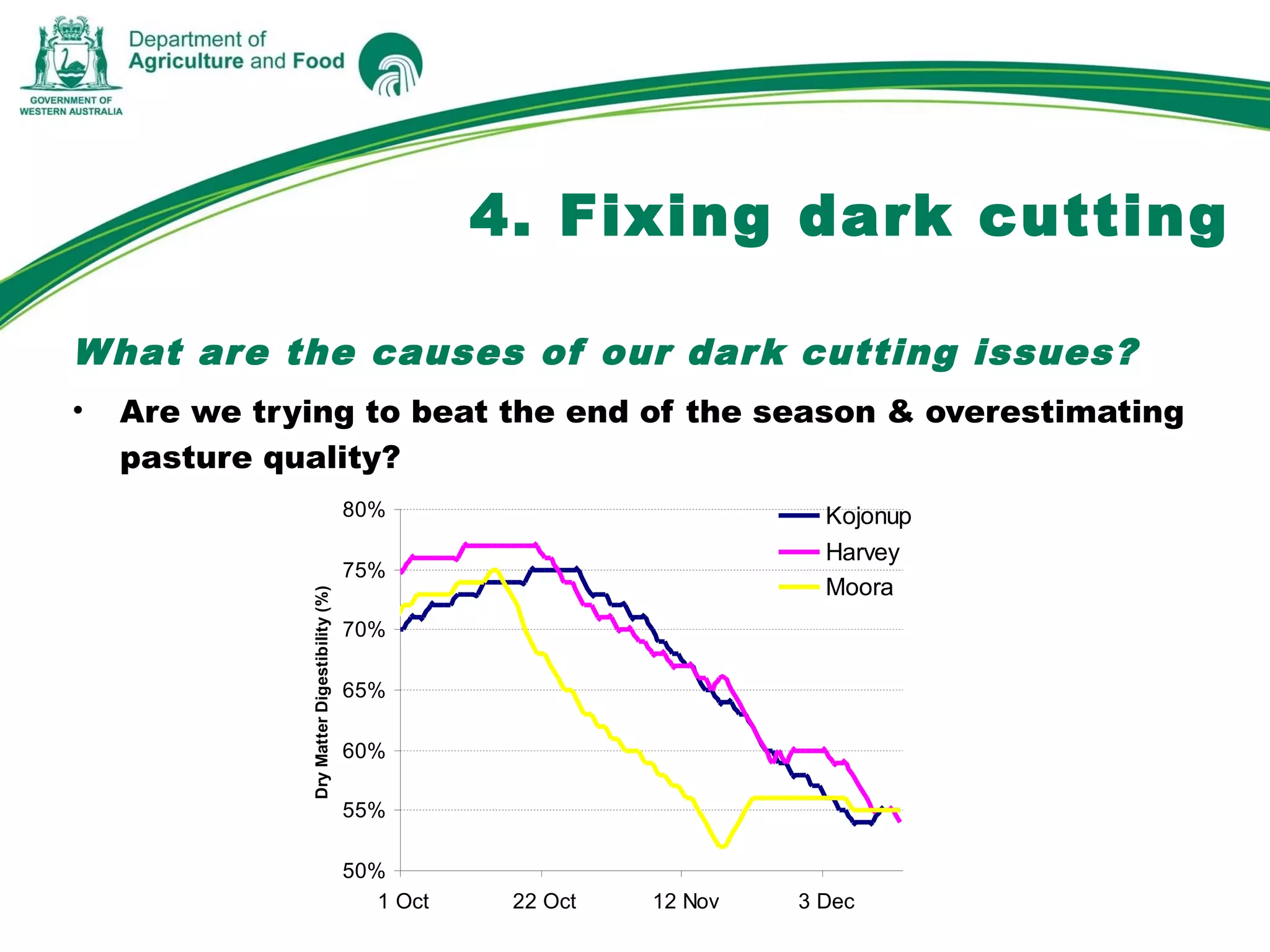

This document discusses Meat Standards Australia (MSA) compliance rates in Western Australia (WA). It notes that in 2009/2010, over 1 million head of cattle were graded in WA, with 17.3% of cattle graded and 87.4% meeting MSA specifications. "Dark cutting," or high pH meat with lower eating quality, is identified as a key reason for non-compliance. The causes of dark cutting are explored, with low muscle glycogen levels from inadequate nutrition and management identified as the underlying issue. Strategies to address dark cutting like improving pasture quality and cattle growth rates through additional feeding are recommended.