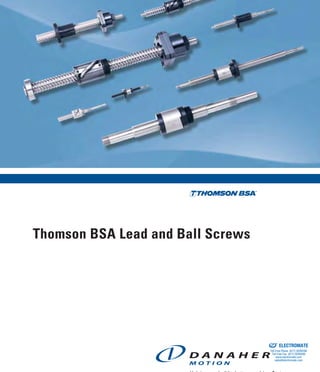

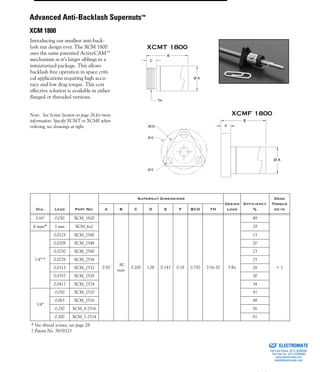

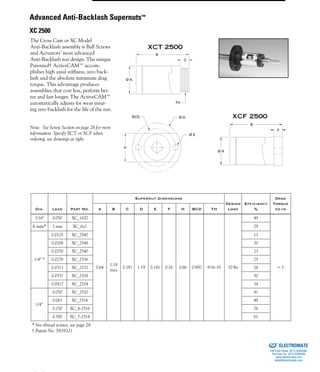

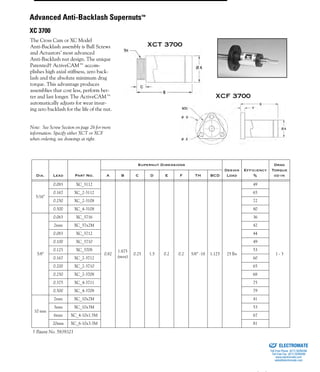

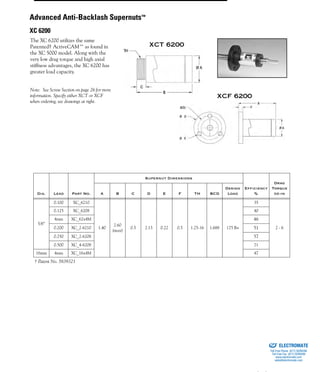

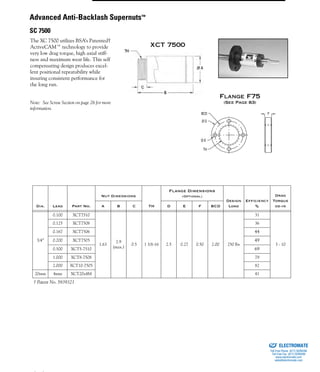

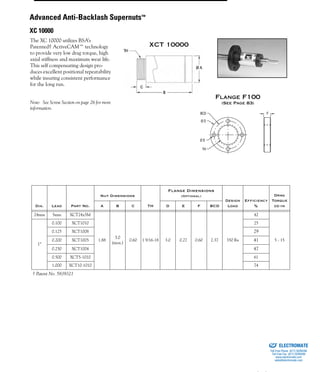

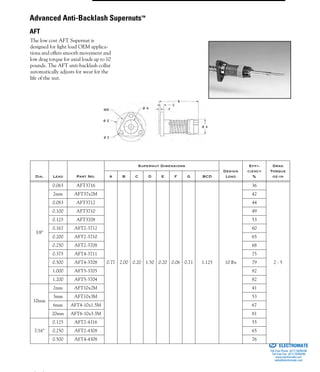

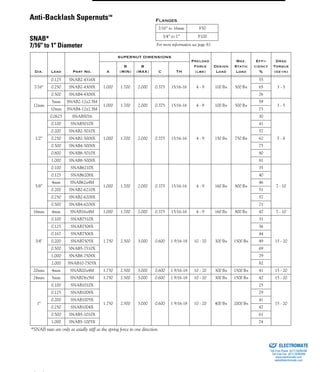

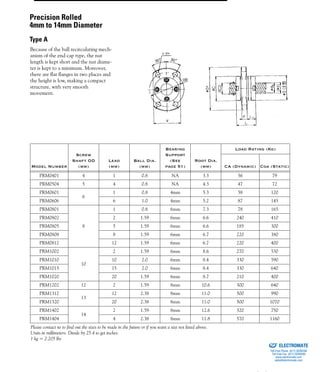

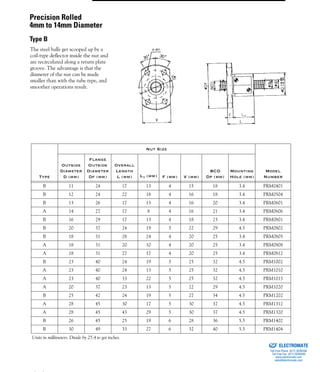

The document describes Thomson BSA Lead and Ball Screws, including Supernuts & Lead Screws. It provides an overview of Ball Screws and Actuators' precision lead screw assemblies and Supernuts. It then describes their Advanced Anti-Backlash Supernuts, including the smallest XCM 1800 nut design, which uses a patented ActiveCAMTM mechanism to allow for backlash-free operation in space-critical applications. Dimensions and specifications are provided for various nut sizes.