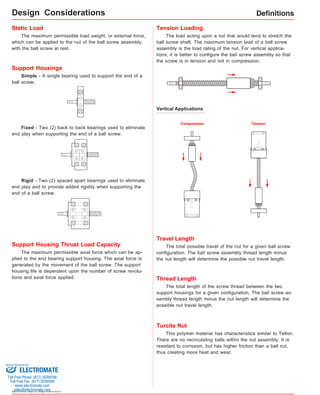

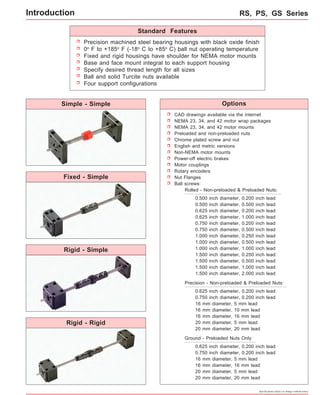

This document provides information about linear motion ball screw assemblies sold by Electromate. It includes specifications and comparisons of their RS, PS, and GS series ball screw assemblies. It discusses design considerations for selecting the proper assembly such as required precision, load capacity, speed, noise level, life, and cost. Housing and nut options are described that affect smoothness, backlash, and other performance characteristics.