Clouder maintenance flyer

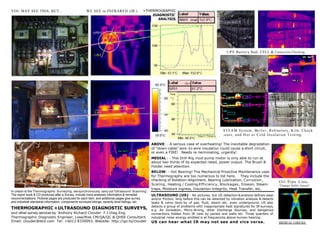

- 1. YOU MAY SEE THIS, BUT... WE SEE in INFRARED (IR.) +THERMOGRAPHIC____ DIAGNOSTIC ___ANALYSIS. U P S B a t t e r y Bank. CELL & Connection Checking. STEAM System, Bo i l e r , Refractory, Kiln, Check -o u t s , a n d H o t o r C o l d I n s u l a t i o n T e s t i n g . ABOVE: - A serious case of overheating! The inevitable degradation of "down-cable” wire -to-wire insulation could cause a short circuit, or even a FIRE! Needs re -terminating, urgently! Max: 86.8°C MEDIAL : - This Drill-Rig mud-pump motor is only able to run at about two thirds of its expected rated, power output. The Brush & Holder need attention. BELOW: - Hot Bearing! The Mechanical Proactive Maintenance uses for Thermography are too numerous to list here. They include the checking of Rotation-Alignment, Bearing Lubrication, Corrosion , Oil Pipe Line. Scaling , Heating / Cooling-Efficiency, Blockages , Erosion, Steam- Flange bolts loose! traps, Moisture ingress, Insulation-Integrity, Heat Transfer, etc. In unison to the Thermographic Surveying , we synchronously carry out 'Ultrasound Scanning '. The report book & CD produced after a Survey, include more analyses information & remedial ULTRASOUND (US):- No pictures, but US detection & analysis defines wear recommendations. Pictorial pages are produced for each item, and additional pages give survey and/or friction, long before this can be detected by vibration analysis & detects and industrial standards information, components surveyed listings, severity level listings, etc. leaks & valve blow-by of gas, fluid, steam etc. even underground. US also detects a group of problems with inappropriate heat signatures for IR-surveys, THERMOGRAPHIC + ULTRASOUND DIAGNOSTIC SURVEYS, e.g. Air Ionisation, Micro-Arcing, other Discharge Sources, and dangerous and other survey services by Anthony Richard Clouder F.I.Diag.Eng. connections hidden from IR view by panels and walls etc. Three quarters of Thermographic Diagnostic Engineer, Lose/Risk CM/QA/QC & QHSE Consultant. industrial noise energy emitted is at frequencies above human hearing. Email: clouder@ekit.com Tel: +6013 8330093. Website: http://go.to/clouder US can hear what IR may not see and vice versa. MEDICAL CHECKS.

- 2. Infrared/Thermographic Inspections for Pro-active Maintenance. INDUSTRIAL FACILITIES & BUILDING SERVICES. What we. can do for you. INFRARED / THERMOGRAPHIC and ULTRASOUND INSPECTION A prerequisite for effective asset protection & recommended as a yearly check. • Using Infrared Imaging with Thermographic analyses, and coupled with Ultrasound inspection, we surveyor can find existing & potential faults in electrical systems & other facilities. • This state-of-the-art survey can “see” things that the eye cannot see and “hear” things that the ear cannot hear. • The report will give a full analysis and incorporate suggestions on how our client can carry out remedial action and plan a pro-active maintenance schedule. • Immediately done corrective action can be re-inspected while the surveyor is still on site. OUTCOMES REDUCE fire hazards AVOID disruption of critical services MINIMISE maintenance costs PREVENT emergency shutdowns DECREASE overhauls and replacements ELIMINATE loss of production OUR DIAGNOSTIC INSPECTION ENGINEER • 40 years experience in the field of Industrial Diagnostic Inspections. • 30 years experience in Infrared/Thermographic Surveys, and a further 10+ years in Infrared Photography. • ASNT SNT-TC Certified Thermographer, 1988 • Fellow of the Institute of Diagnostic Engineers, United Kingdom. • Founding year Member of the United Kingdom Thermographers Association. • Thermal Imaging in Medicine Certified (Glamorgan University, UK, 2006). • Consultant -Trainer with the Institute of Infrared Thermography (Intl.) for the Asia-Pacific region. • Affiliate of the British Institute of Non-Destructive Testing. • Holds full Off-Shore OPITO international safety pass & medical for offshore Vessels and Oil & Gas work. A Thermographic surveyor should be competent & extensively experienced in the use of Thermographic/ Infrared Cameras for both plant and building inspections. It is also essential that the Surveyor has a thorough knowledge & hands-on experience of the type of industrial equipment, plant processes, building services, & a full theoretical, design, & application knowledge of the equipment, object, or facility that is to be inspected. In addition to all of the above, our surveyor, together with degrees in engineering & management, has a vast knowledge & hands-on experience in all fields of industrial & building maintenance, process control, mechanics, etc. and as an HNC in Electrical and Electronic Engineering.

- 3. INDUSTRIAL PREDICTIVE & PROACTIVE MAINTENANCE. CONDITION BASED MAINTENANCE SURVEYS utilising advanced THERMOGRAPHIC & ULTRASOUND diagnostic inspection technology. The objectives of utilising our advanced THERMOGRAPHIC INFRARED-IMAGING and ULTRASOUND (IR+US) technology is to supply our clients with the necessary, Infrared imaged, Photographed and Thermographically analysed, and written technical reports for the carrying out of all necessary remedial actions. This is for the assurance of both the trouble free commissioning of new installations, and a reliable continuation of production and plant usage for the full and extended life of equipment and the plant installation. The survey reports include a severity level analysis of all faults found with advice on how rectification work of the faults can be carried out so that clients can include these pro-active measures into their preventative maintenance schedule. Thermography backed up by Ultrasound assures that the above objective is achieved without utilising invasive NDT techniques that may disrupt work schedules and/or production. IR+US surveys also enable a complete inspection of all of the plant in its entirety. This is opposed to the random selective testing nature of conventional NDT, which is confined to testing only small sample arrears within the plant and also requires a physical contact with equipment that can give rise to access problems. e.g. Radiography, Eddy-current, Neutron backscatter, Ultrasonic induction, etc. The Industrial plant and Building services IR+US surveys can typically cover, though are not limited to the following items of plant equipment: - (If you do not see your area of interest below, please ask us.) q HV and LV Switch gear... Ø Incoming & outgoing feeder & bus-bar connections. q Rotary Non- Break UPS systems... Ø Control panel terminations & connections, Bearings. q Static UPS systems... Ø Battery cells. Connections and Switchgear. q Power Generator Systems... Ø Terminals. Bus-bar connections and bearings. q MCC and SCR Systems... Ø Components, Terminals. Bus-bar connections etc. q Battery Charging Systems... Ø Terminals, Cells, Semi Conductor devices, etc. q Instrument & Fire panels c/w power supplies... Ø Terminals, Bus-bar connections. AC/DC converters. q Relay Panels... Ø Relay and Switching devices. Connections. q Heat Tracing... Ø Connections, Heat pattern and Insulation. q Analysers & Flow / Level Instrumentation etc... Ø Terminal connections. Blockage and leakage. q Power Cable Runs... Ø Overloading. Phase imbalance. q Rotating & Belt or Chain drives... Ø Friction and/or Overheating. Alignment, Bearings. q Motors and Heaters... Ø Overloading and connections. Power factor faults. q Heater and Exchanger pumps... Ø Heating patterns and insulation. Flow path checks. q Compressors, Turbine Generators... Ø Exhaust heat patterns and insulation. q Insulated Vessels and Piping... Ø Insulation integrity. sludge, corrosion, erosion. q Boilers and Furnaces... Ø Hot spots in tubes, casings, walls, exhaust-ducts. q Flares... Ø Flare tip & Radiated Heat effects. q Ducting systems... Ø Temperature gradients. Insulation. q Chilled or Hot Water Systems... Ø Cooling & Heating patterns. Insulation / Lagging. q De-Humidifying & Weather sealing... Ø Humidity & Moister ingress & temp. consistency. q Coal stockpiles and Mines... Ø Hidden Smouldering fires. Plant equipment QC. q Grain silos. Ammunition stores... Ø Moisture ingress. Combustion risks. q Laminated materials... Ø Delamination. Moisture ingress. q Building structures (Envelope) Ø Moisture ingress. Material anomalies. Heat transfer. q Hydraulic Systems, Gas or Fluid piping & vessels, Ø Leakage, Hot spots. Water logging, Blockages. Relief valves, Control valves. Steam-Traps... Functional checks.

- 4. AVOIDANCE OF CORROSION RELATED FAULTS IN ELECTRICAL SYSTEMS. PROTECTION. Vapour Phase Corrosion Inhibitors (V.P.C.I.‘s) developed by SENSON are specifically designed to tackle and prevent the above problems. Over an extended period of time, these products developed by SENSON give-off a controlled amount of non-CFC, non-toxic, non-smelling V.P.C.I.‘s. This converts both Acidic and Alkaline gases to a neutral non-corrosive PH 7. V.P.C.I.’s organic molecules attach themselves to metal, repelling moisture and forming a protective barrier even underneath the electronic components, and inhibits corrosive activities. V.P.C.I. protection is available in Sprays, Greases, Cleaners, Conformal-Coatings, and encapsulated vapour-pads for placement inside of Instrument and Switchgear enclosures, etc. SENSON Technology Pty. Ltd. is a NATO defence appointed manufacture of V.P.C.I.’s (Code No. Z5410) INSPECTION. Corrosion that may pre-exist between connecting services, crimp-connections and switch contacts etc. may be present due to contamination during equipment installation and PLEASE CONTACT MY AGENT IN YOUR REGION. will create “resistance related heating.” There may or contact me directly. also be similar pre-existing corrosion across Email: clouder@tm.net.my boards and insulators that may create “tracking.” or These problems can be found by having a Thermographic@gmail.com combined THERMOGRAPHIC/Infrared-Imaging and Ultrasound survey done by a Diagnostic Engineer. Mobile/SMS-Text +60138330093 This type of survey will also reveal non-corrosion related problems such as loose connections, faulty Skype: ARCLOUDER components, electrical fire hazards etc. These I AM ABLE TO TRAVEL ANYWHERE WORLDWIDE problems are easily fixed once they are diagnosed. and have an OPITO OFFSHORE SAFETY PASS. CLOUDER Thermographic Diagnostics (UK) S.E.Asia services. I AM BASED IN MALAYSIA & BRUNEI.