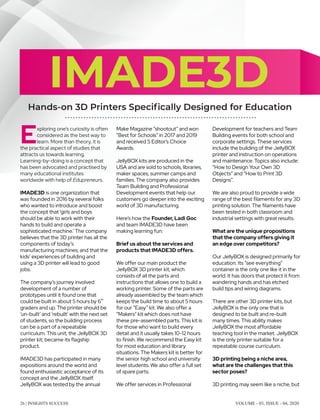

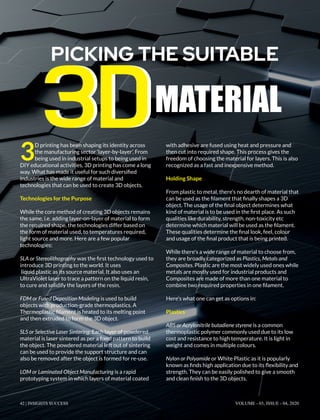

The document discusses the evolution and applications of 3D printing technology across various industries, highlighting its significance in manufacturing, healthcare, and education. It emphasizes the technology's capability to create prototypes at lower costs and its potential to revolutionize medical practices through custom organs, prosthetics, and training tools. The issue features innovative companies in the 3D printing sector, including Apium Additive Technologies and Genius Printers, while also exploring emerging materials and future advancements in the field.