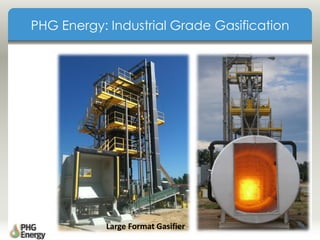

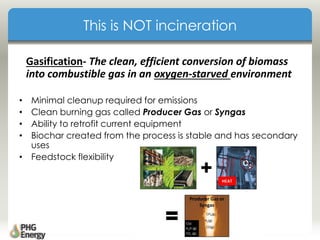

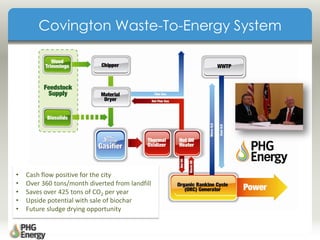

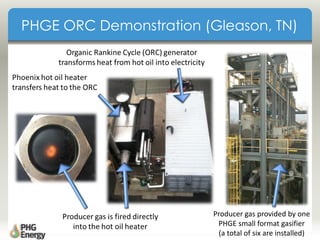

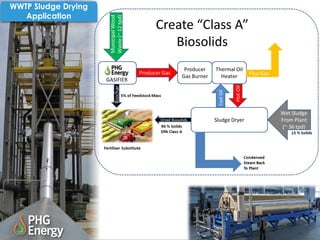

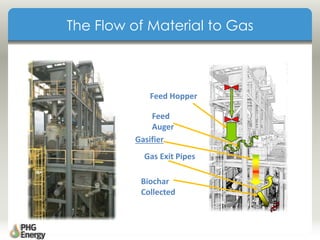

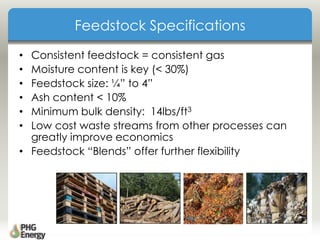

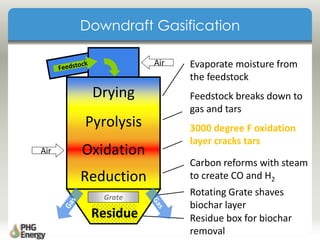

This document discusses industrial grade gasification technology provided by PHG Energy. It can gasify a variety of feedstocks to produce a clean burning syngas while also creating biochar. The process is not incineration and requires minimal emissions cleanup. It has been implemented in a waste-to-energy system in Covington, TN that saves the city on disposal costs while generating revenue from biochar sales and reducing landfill waste and CO2 emissions. PHG Energy systems can also be used for applications like wastewater treatment plant sludge drying. The technology enables a cost-effective way to convert local waste streams into renewable energy and useful byproducts.