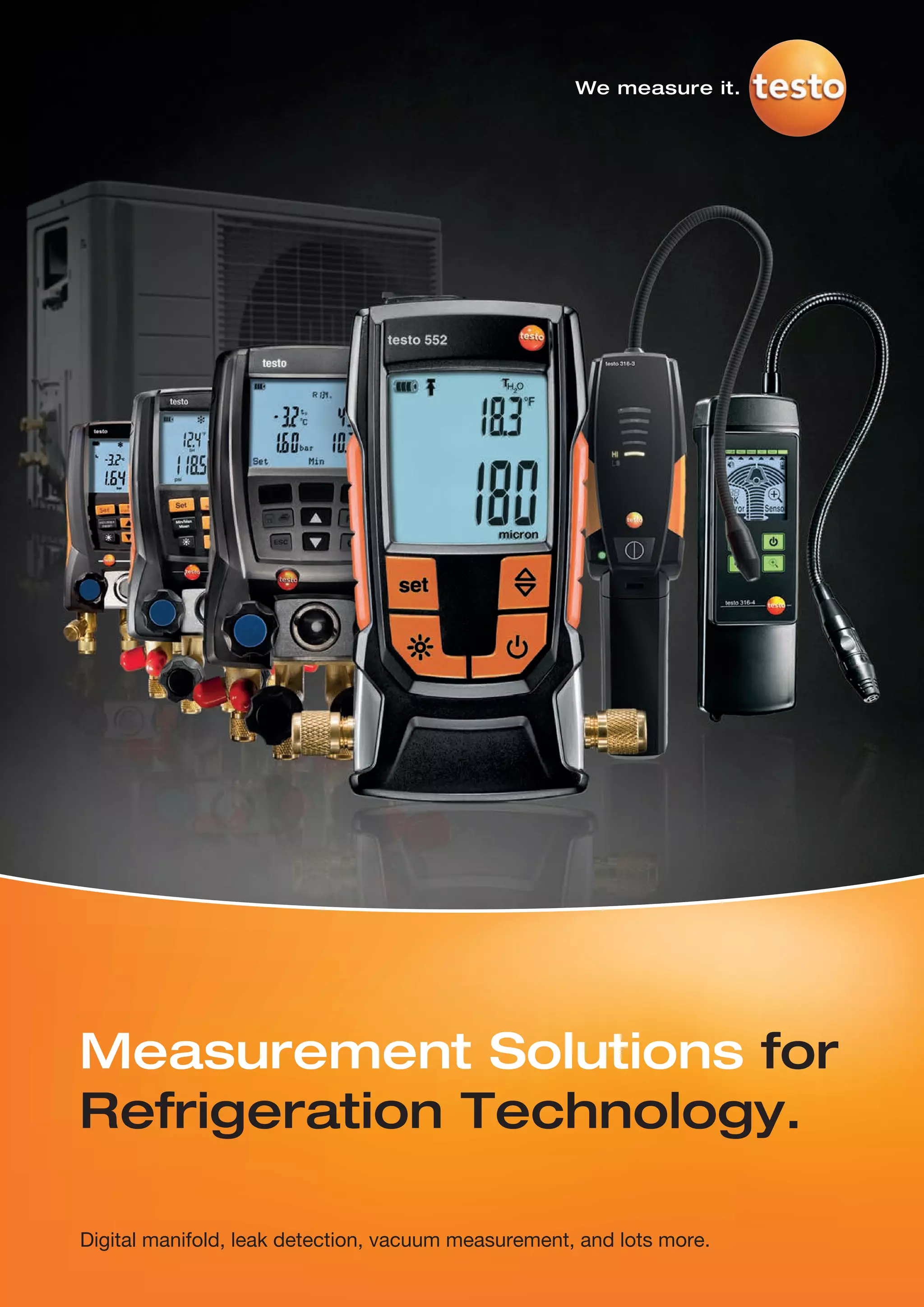

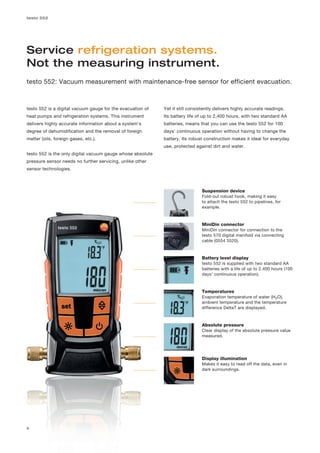

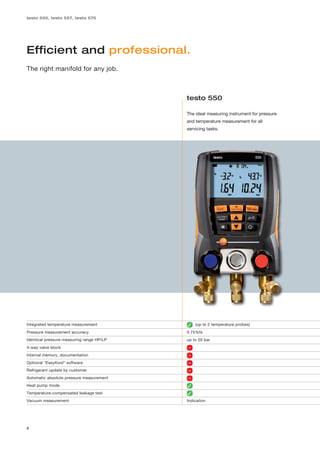

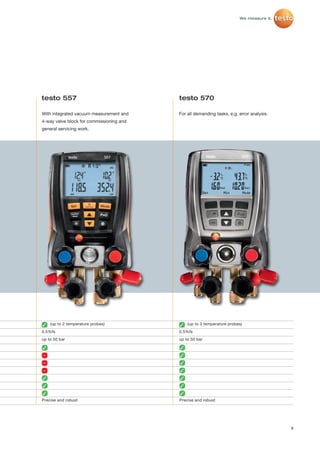

Testo manufactures digital refrigeration technology tools that provide complete solutions for commissioning and maintaining refrigeration systems and heat pumps. Their digital manifolds can measure a wide range of parameters like pressure, temperature, and vacuum readings quickly and accurately. Data can be stored, evaluated, and printed out on-site. The new testo 552 digital vacuum gauge uses a maintenance-free absolute pressure sensor to efficiently evacuate systems and provide permanently reliable measurement results without sensor cleaning.