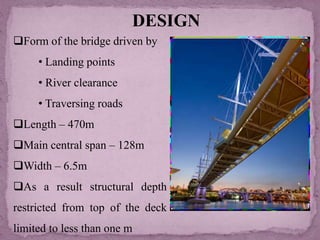

The document defines tensegrity structures as structures that use continuous tension and discontinuous compression to support weight and resist forces without experiencing torque. Tensegrity structures have advantages like being lightweight, self-stable, and able to respond uniformly to stresses. An example is the Kurilpa Foot Bridge in Brisbane, Australia, which uses a tensegrity design of steel struts, cables, and a composite deck to form a 128m central span. Tensegrity structures show promise for efficient structural design but also have challenges like bar congestion in larger designs and complex fabrication.