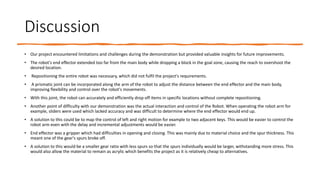

The document describes a student robotics project to design and test a remote-controlled robot capable of performing tasks required to build a colony on Mars, such as navigating obstacles and picking up building materials. The robot was tested in a mock Martian terrain containing obstacles and items to pick up. While the robot could navigate the terrain and pick up an item, it struggled to accurately drop off the item at the destination. The document discusses improvements that could enhance the robot's ability to complete the required tasks.

![Referencing:

• Goldman Sachs, 2017. Space Exploration: The Next Investment Frontier. Retrieved from

https://www.goldmansachs.com/insights/podcasts/episodes/05-22-2017-noah-

poponak.html

• G. Madhavan Nair., K.R. Sridhara Murthi., M.Y.S. Prasad., 2008. Strategic, technological

and ethical aspects of establishing colonies on Moon and Mars, Acta Astronautica.

Volume 63, Issues 11 – 12, Pages 1337 – 1342.

• NASA. (2023). The Fact and Fiction of Martian Dust Storms. [online] Available at:

https://www.nasa.gov/feature/goddard/the-fact-and-fiction-of-martian-dust-storms.](https://image.slidesharecdn.com/team15roboticspresentation-230428021119-adec1b4b/85/Team-15-Robotics-Presentation-pptx-19-320.jpg)