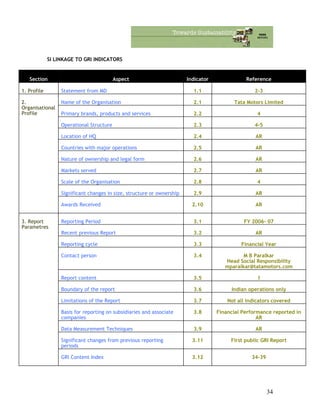

Tata Motors' sustainability report provides an overview of the company's economic, social, and environmental performance in fiscal year 2006-2007. Key highlights include:

1) Tata Motors achieved record financial performance with over a 33% increase in revenue and sales volume surpassing 500,000 vehicles for the first time.

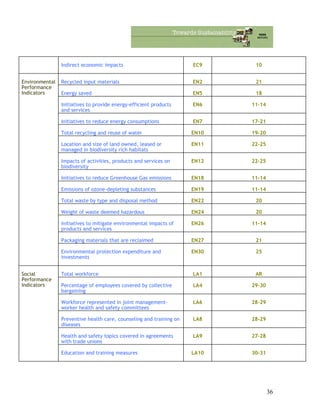

2) The report describes Tata Motors' initiatives to reduce emissions and improve fuel efficiency, as well as its social programs focused on community development, health, and education.

3) Tata Motors has management systems in place to engage stakeholders, mitigate risks, and ensure compliance on issues like the environment, labor practices, and ethics.