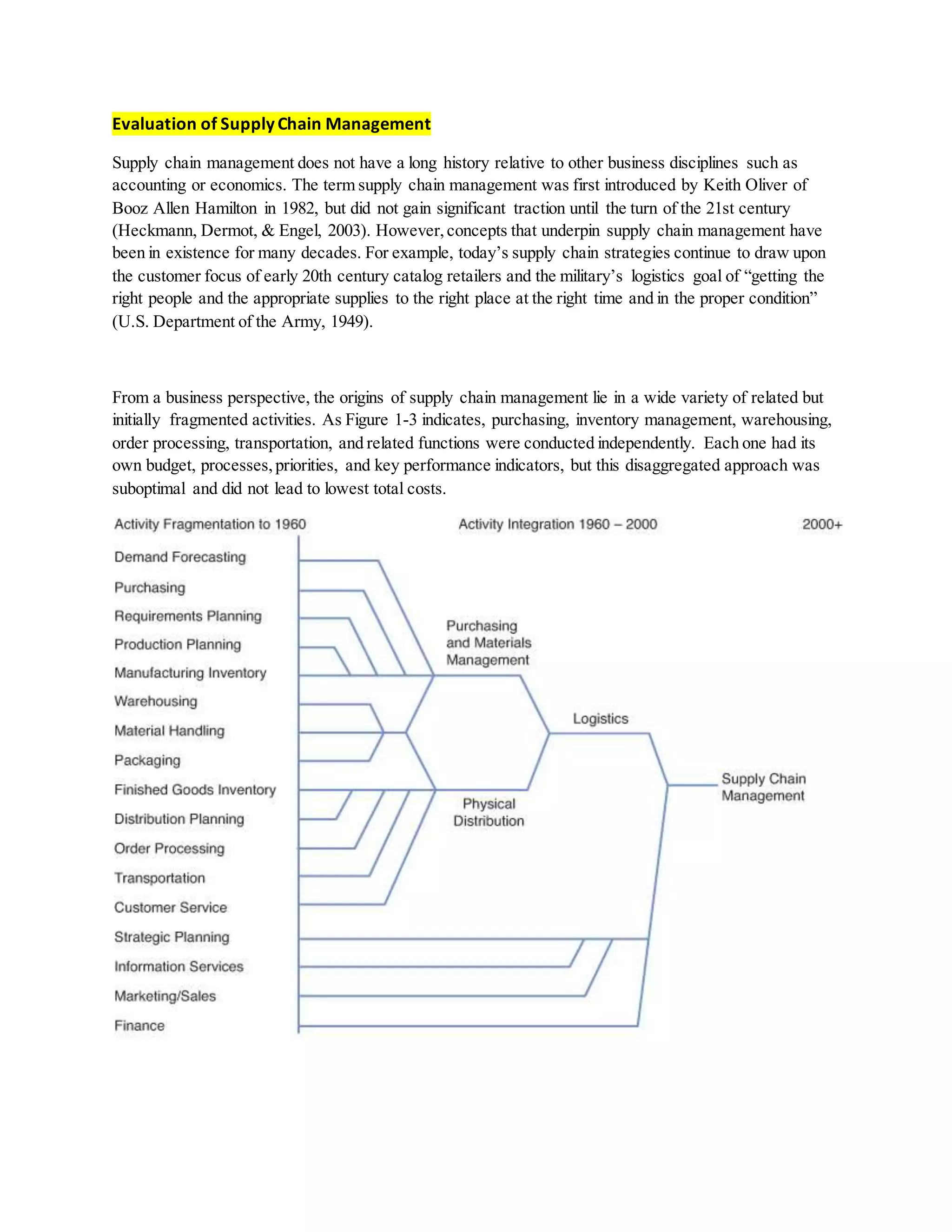

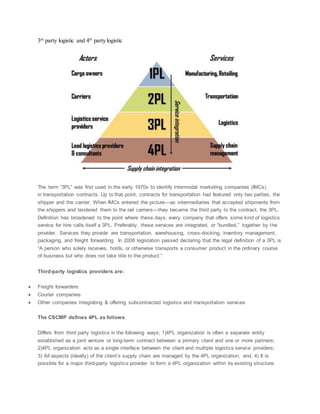

The document discusses supply chain management, including its history and key components. It begins with an overview of how supply chain management evolved from initially fragmented business functions like purchasing and inventory management integrating over time. The document then defines supply chain management as combining art and science to improve how companies source raw materials, produce products, deliver to customers, and manage returns. It outlines the basic components of supply chain management as plan, source, make, deliver, and return.