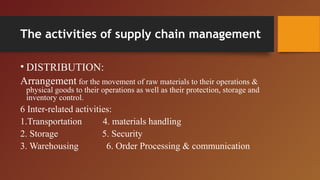

This document discusses supply chain management. It defines supply chain management as all operations linked to provide goods and services to end customers. The objectives of supply chain management are listed as quality, speed, dependability, flexibility and cost. The key activities of supply chain management are purchasing, physical distribution management, transportation, storage, warehousing, order processing and communication. The document also discusses relationships in supply chains between businesses and customers, and types of partnerships. It outlines approaches to improving supply chain performance, including the Supply Chain Operations Reference (SCOR) model of business process modeling, benchmarking and best practices analysis.