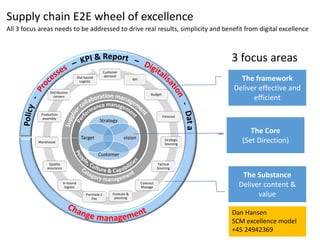

Supply Chain Excellence Model Addresses 3 Focus Areas

- 1. 1 Supply chain E2E wheel of excellence All 3 focus areas needs to be addressed to drive real results, simplicity and benefit from digital excellence Strategy vision Customer Target Customer demand NPI Budget Forecast Strategic Sourcing Tactical Sourcing Contract Manage Distribution centers Forecast & planning In bound logistic Quality assurance Warehouse Purchase 2 Pay Production assembly Out bound Logistic The framework Deliver effective and efficient The Core (Set Direction) The Substance Deliver content & value 3 focus areas Dan Hansen SCM excellence model +45 24942369

- 2. Procurement and Supply Chain Maturity Model 16 December 2016 Dan.han@mail.dk Price reduction phase Value management supplier cooperation Total Value of Ownership supplier collaboration Integrated supply networks Level 1 Level 2 Level 3 Level 4 Level 5 Level 6 Level 7 Level 8 Level 9 Level 10 Price negotiation, separate buys Leveraged volumes – price negotiation Business-wide leveraged volumes – price negotiation Cost reduction negotiations on today’s expenditure Cost targeting introduced with key suppliers First major cost benefits flow from joint cost mgt./ productivity projects First major time-benefits flow from joint planning on multi project basis Time & Cost benefits are optimised Benefits are institutionalised and a sustainable competitive advantage is established Procurement and supply chain and enterprise maturity KPIs for price performance Procurement savings locked in to budget KPIs include supplier cost reductions and more complex SRM metrics KPIs driven by customer satisfaction mode KPIs move to <___> total cost & productivity metrics KPIs include collaborative targets & benchmarked competitive advantage metrics KPIs centre on efficiency & speed along & between supply chain members Basic purchasing procedures in place Procurement mgt. capable Procurement and Supply Chain vision, mission & business strategy agreed with functions & business mgt. Procurement SAAS solution available, including Master Data governance and aligned volume / planing info route Skills analysis in progress Initial training in progress Ways of working roles, skills, structures, processes & internal/ external. Interfaces agreed. Business benefits defined KPIs include inventory metrics Noncompliant spend identified. Initial actions taken to extend contracts company wide. Spend item common coding in progress 75 % compliance on contracted spend Supplier spend database available Initial top talent recruitment commenced. Engineering & Finance rotation to Procurement commences. Cross functional training commences Change management projects funded for Procurement/ business process improvement KPIs include SRM metrics Initial benefits achieved from supplier cost reductions are somewhat shared with suppliers Common inventory mgt. introduced to optimise inventories in division/region. VMI introduced. Mgt. control exists over 75% of external spend. Item coding >50% complete. Outsourced logistics mgt. introduced. Key positions filled to 50%. Focused & targeted training portfolio introduced Clear evidence of new processes working in category mgt. & capital procurement. Suppliers experience changes in approach Low value / indirect spend outsourced Total expenditure is cracked and reported All key positions filled with top talent people. Focused training provided to all people involved with suppliers & supply chain Category teams work effectively in all areas of spend including cross division leverage & strategies. Capital procurement engaged in cross project resource & demand leveraging. Supplier relations developed on mgt. level. Supplier strategies linked to business plans and strategies All spend is leveraged with supply chain partners All transactions with suppliers are system linked & automated. Supplier/contracto r performance >98% full customer satisfaction Key suppliers & contractors involved at appropriate early stage of projects to assist in planning and project development. Relationship mgt. deployed as key enabler to supplier positioning & to support full release of supplier potential. Second tier suppliers & subcontractors included in comms. and planning links. Supplier councils established between exec & key supplier CEOs to calibrate & agree common business & supply chain strategies. Temporary role exchange commence between key engineering & operating staff & the external supply chain to facilitate collaboration Top talent recycles out of procurement to future careers Customers of choice status achieved with key supplier community Procurement & supply chain skills are embedded into engineering & operations functions. Job/role boundaries are deemphasized. Procurement transactions are equally prompted by supplier or customer Procurement mgt. assumes coach role Logistics is fully outsourced to 3PL/4PL providers if not a business core competence Operations and engineering focus on core competencies Competitive supply networks emerge as virtual entities. Multi enterprise function working commences similar to Kelretsu Talent supply chain and career paths created across supply network Analysts and investors acknowledge strategies and collective business network Market rewards share prices Integrated enterprise wide supply networks work bilaterally & multilaterally to provide goods equipment & services solutions to time, cost & profitability parameters for all operations & entities Enterprise assumes sector lead with sustainable competitive advantage in Procurement & supply chain performance Mgt. /business process People Systems/logistics General status KPI approach Key ERP/MRP operational & effective E-transaction systems available