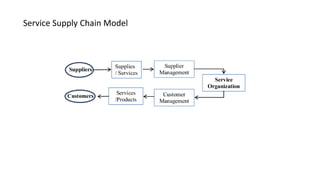

Supply chain management involves the flow of goods and services from suppliers to customers. It includes planning, implementing, and controlling operations along the supply chain to efficiently meet customer needs. The evolution of supply chain management has seen tasks integrate over time from separate materials management and distribution functions to a single management perspective spanning the entire supply chain. Key flows in supply chains include materials, information between partners, and financial flows as customers pay suppliers. Performance is measured through both qualitative and quantitative metrics.