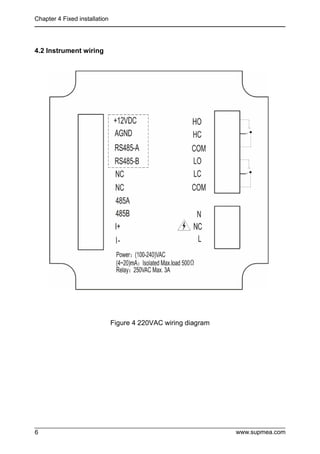

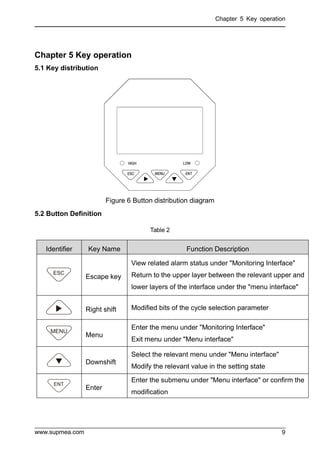

This document is a user manual for a universal controller made by Supmea Automation Co.,Ltd. It provides instructions on installing and operating the controller, including connecting sensors, navigating the interface, setting configurations, troubleshooting, and specifications. Safety precautions are also outlined, such as following instructions to avoid electric shock and ensuring proper ventilation. The controller can monitor multiple water quality parameters using compatible digital sensors.