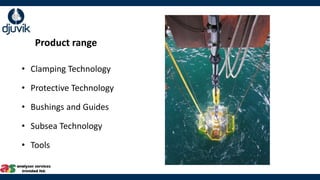

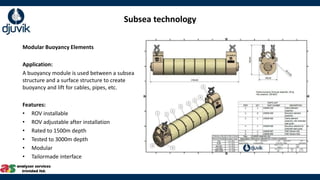

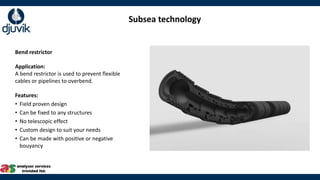

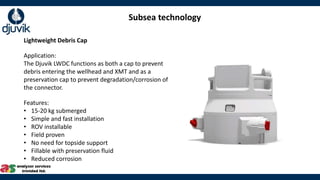

Djuvik is a Norwegian supplier of high-quality engineered polymer products for the offshore oil and gas industry. It produces clamps, protectors, bushings, and other parts through CNC machining of plastics and polymers. Djuvik's products are corrosion resistant, lightweight, customizable, and aim to improve safety and reduce operational costs for customers in drilling, completion, and workover operations.