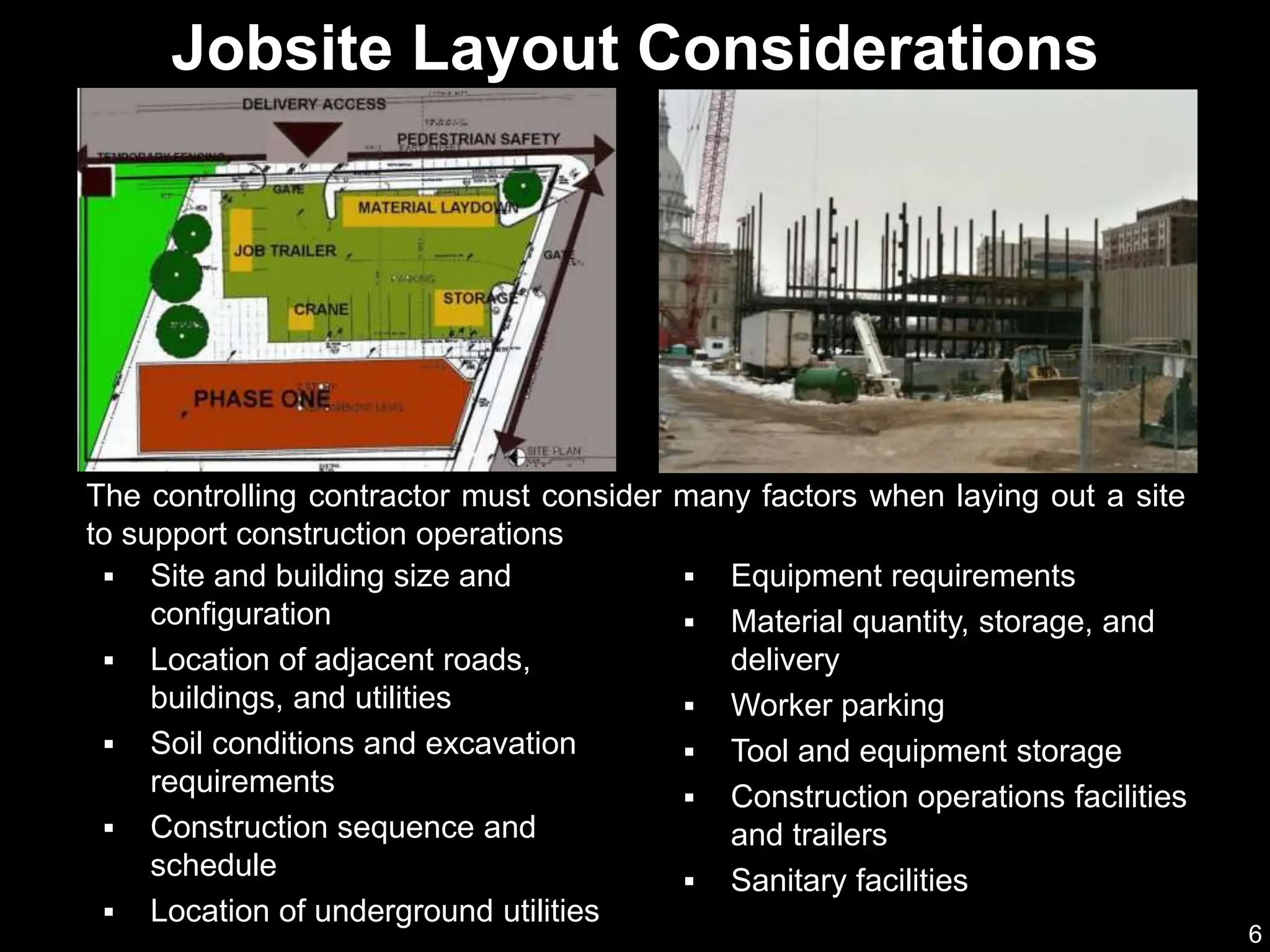

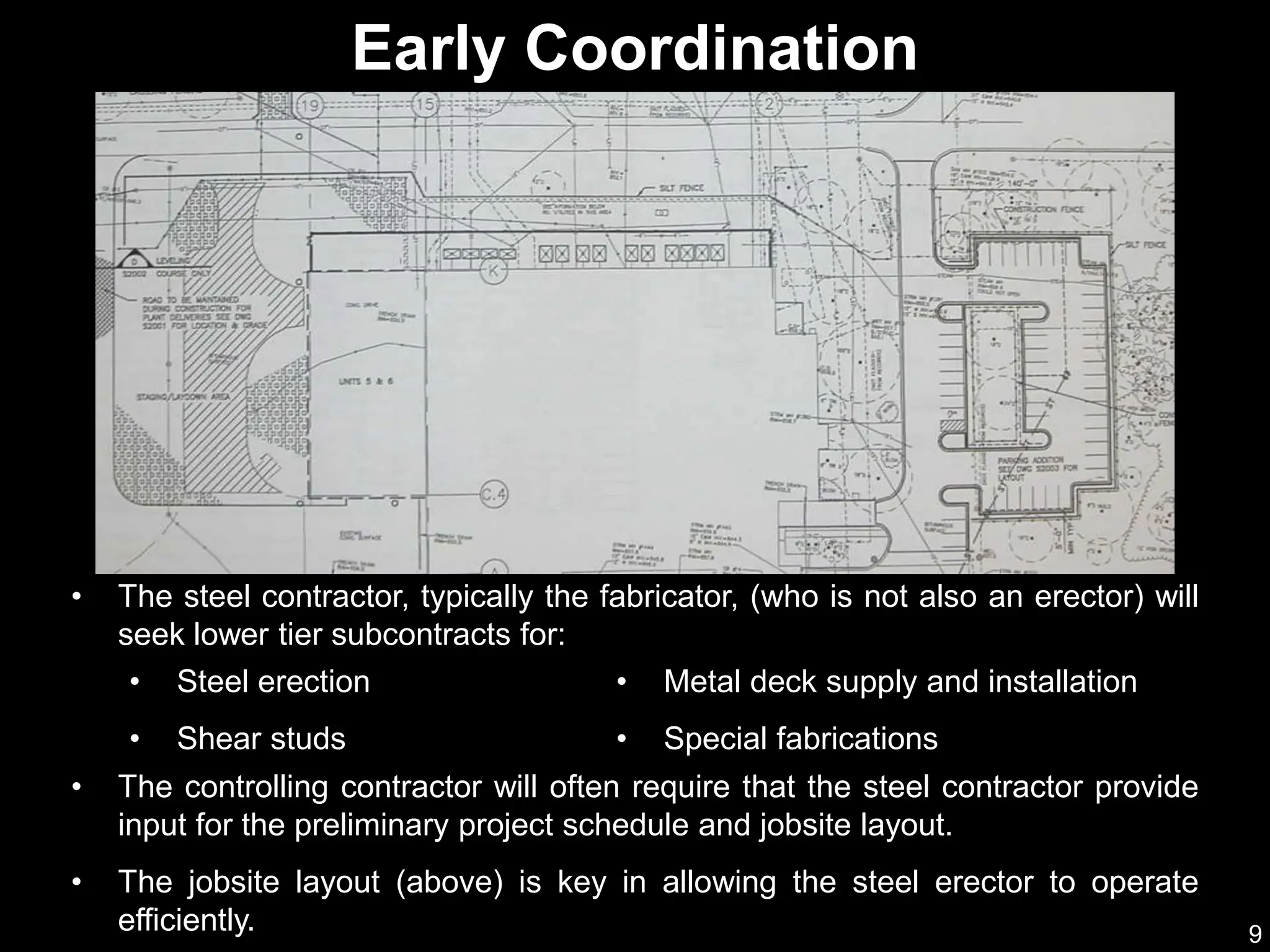

This document provides an overview of considerations for jobsite layout and coordination for structural steel construction projects. It discusses factors like site size and configuration, building footprint, crane locations, laydown areas, access roads, underground utilities, worker parking, and facilities. The presentation emphasizes the importance of early coordination between the controlling contractor and steel contractor to finalize jobsite layout and sequencing plans. Proper planning of schedule, material delivery and erection processes is key to optimizing the structural steel construction process.