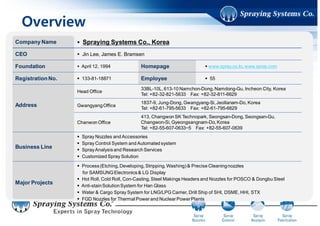

Spraying Systems Co., Korea specializes in manufacturing and providing over 87,000 different spray nozzles and systems, aimed at improving efficiency and product quality across various industries. The company, founded in 1994, has a global presence with ten manufacturing locations and numerous sales offices worldwide, offering tailored solutions and services like spray analysis and control systems. Key customers include Samsung Electronics, LG Display, and various steel and power companies.