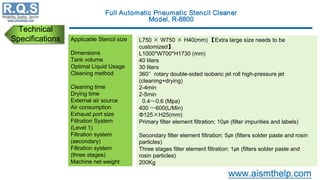

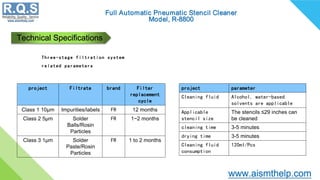

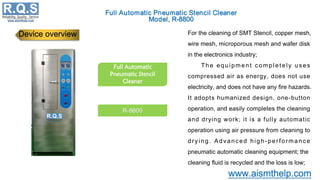

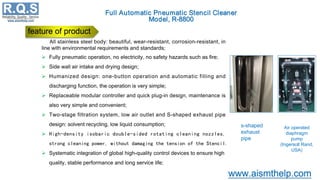

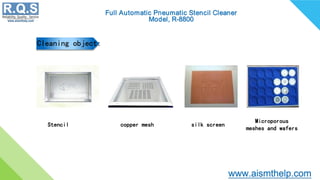

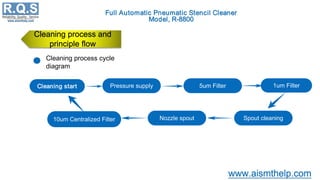

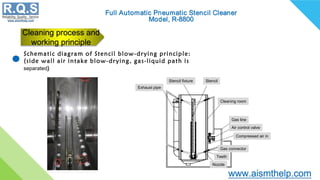

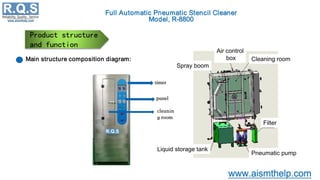

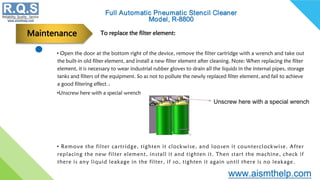

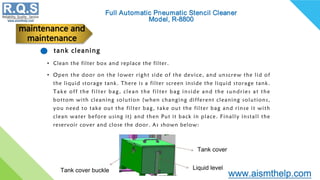

The document outlines the technical specifications and features of a fully pneumatic stencil cleaning machine designed for the SMT industry, emphasizing its efficient cleaning process, which includes a three-stage filtration system and one-button operation. It highlights the machine's safety aspects, such as being electricity-free with low fire hazards, and details maintenance instructions for the filter replacement and cleaning fluid management. The equipment is suitable for various cleaning applications, including stencils, copper meshes, and wafers, and promotes a user-friendly design for convenient operation and maintenance.