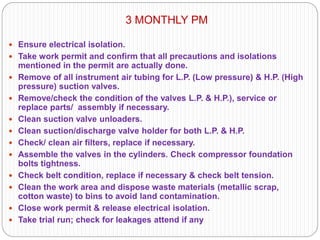

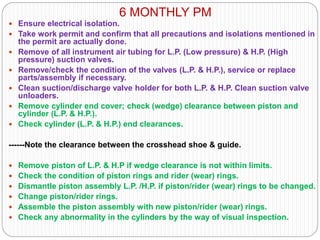

This document outlines the standard operating procedures (SOP) for air compressor maintenance at Petronet LNG Ltd. It describes the three types of preventative maintenance: 3-monthly PM, 6-monthly PM, and 12-monthly or overhaul PM. The SOPs detail the steps to be followed for each type of maintenance, including ensuring safety isolations, inspecting and replacing parts as needed, checking clearances, lubricating, and testing operation upon completion. The goal is to contribute to effective equipment functioning and maintain quality and consistency in work.