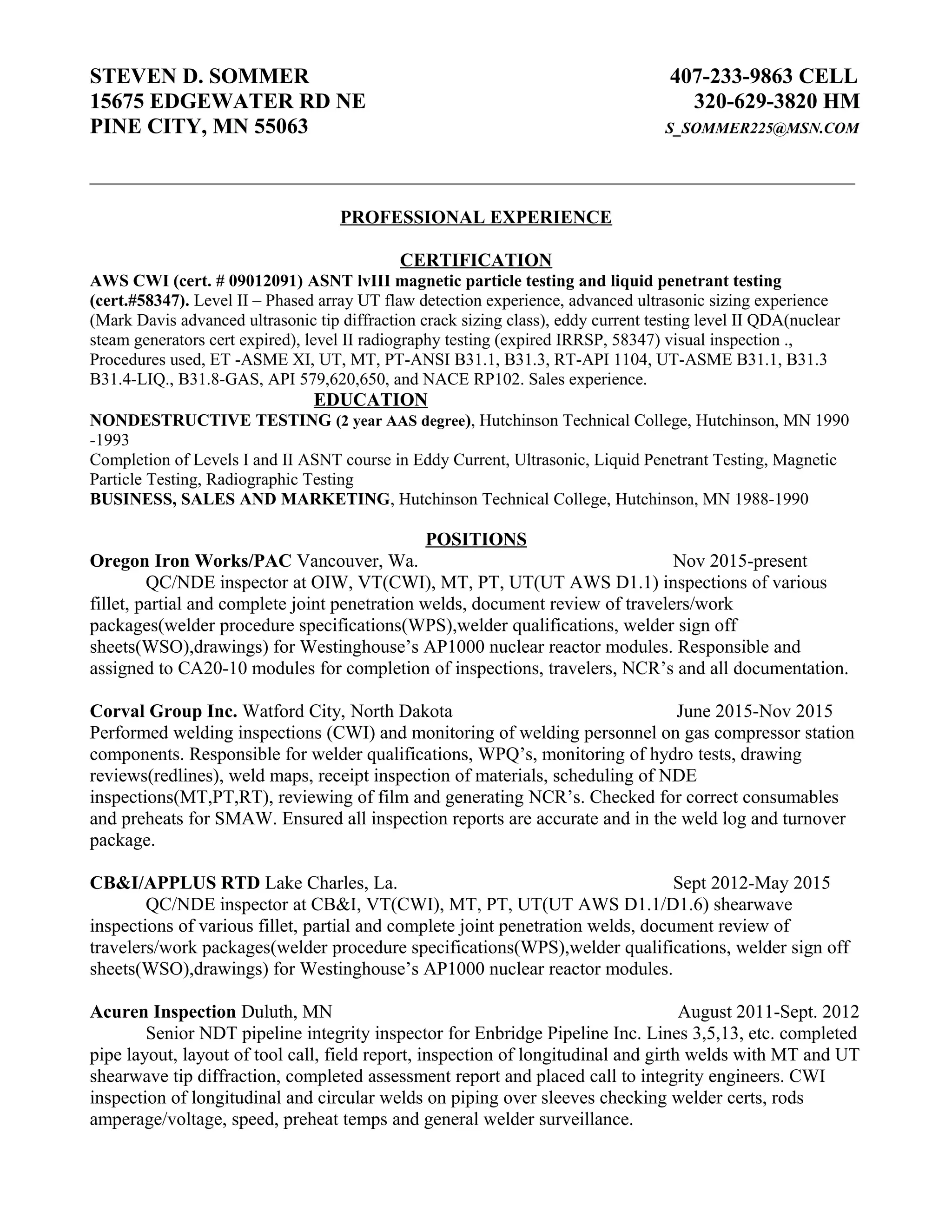

Steven Sommer has over 25 years of experience in non-destructive testing including certifications in UT, MT, PT, RT, and visual inspection. He has worked for various companies performing inspections on pipelines, gas turbines, nuclear reactors, and other industrial equipment. His experience includes developing inspection techniques, supervising inspection teams, and ensuring quality control of welding and non-destructive testing.