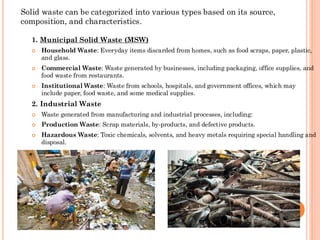

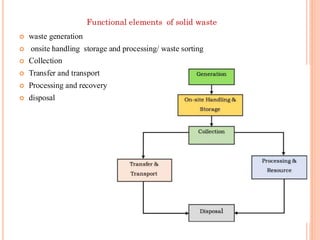

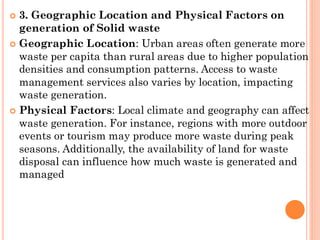

Solid waste management encompasses the control of waste generation and disposal from various sources, including residential, commercial, and industrial activities. Effective waste management protects public health, benefits the environment, enhances community aesthetics, and stimulates economic opportunities. Various types of waste, including municipal, biomedical, hazardous, and agricultural waste, require different management strategies and are influenced by legislation, public awareness, and geographic factors.

![TRANSFER MEAN AND METHOD [

TRANSPORT METHOD]

Motor vehicle transport

Rail road transport

Water transport- barrages, scows and special boards have been used in past

Pneumatic- low pressure vaccum conduit transport system most common application in the transport of waste](https://image.slidesharecdn.com/pptfinal-241127182121-2ce58333/85/Solid-waste-management-of-civil-engineering-95-320.jpg)