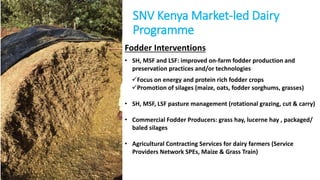

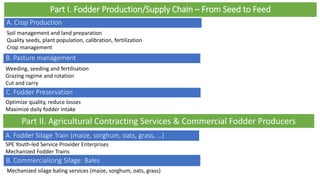

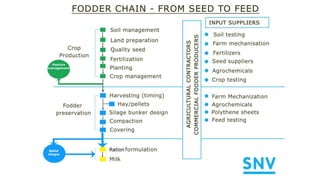

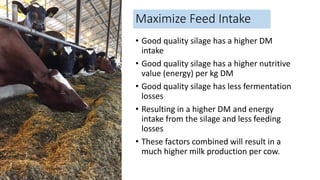

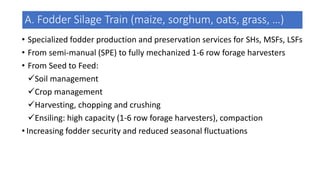

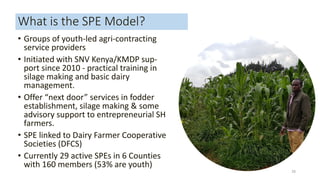

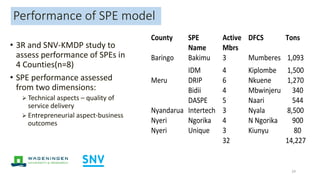

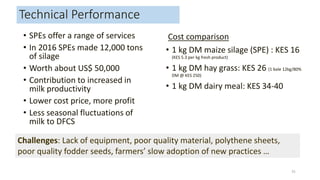

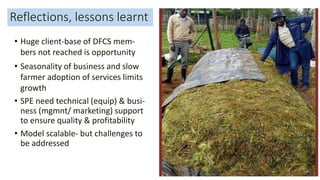

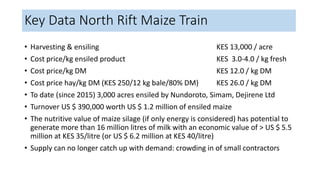

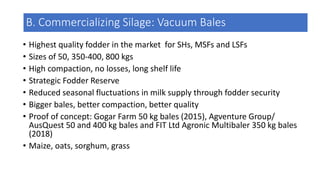

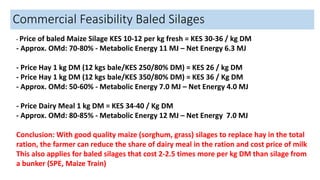

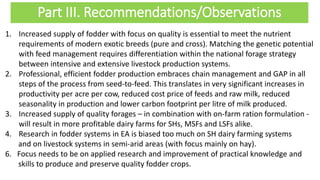

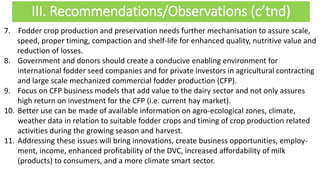

The SNV Kenya Market-Led Dairy Programme (KMDP) focuses on enhancing fodder production and preservation to increase dairy productivity and profitability for farmers. The program implements various interventions, including improved fodder management practices, agricultural contracting services, and youth-led service provider enterprises. Key recommendations emphasize the need for quality fodder supply, mechanization in production, and better alignment of research with local farming needs to boost the dairy sector's sustainability and efficiency.