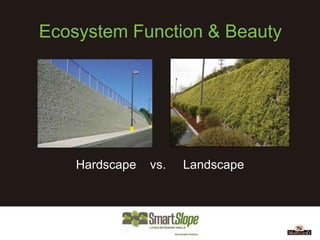

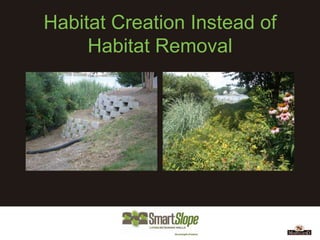

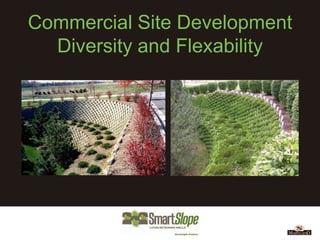

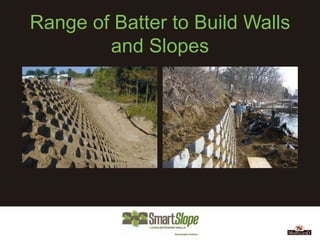

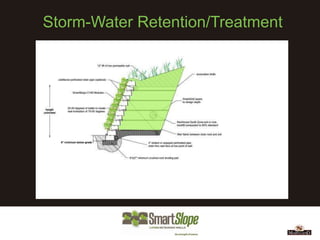

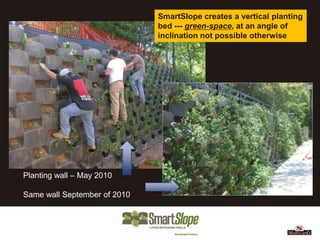

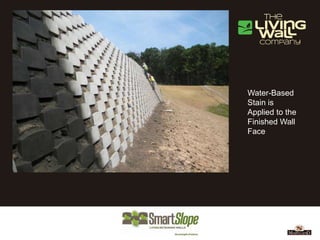

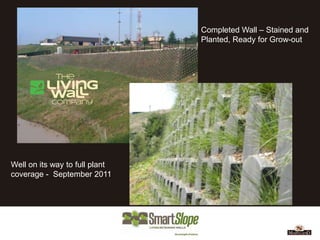

The Smartslope 'Living Retaining Wall System' innovates the industry by integrating ecosystem functions and aesthetics into retaining walls, offering advantages like reduced carbon footprint, storm-water management, and cost savings through less concrete and faster installation. This system enables enhanced plant growth conditions and environmental benefits while being scalable and adaptable for various projects. Designed with recycled materials, it aims to create functional, beautiful retaining walls that contribute positively to habitats and urban landscapes.