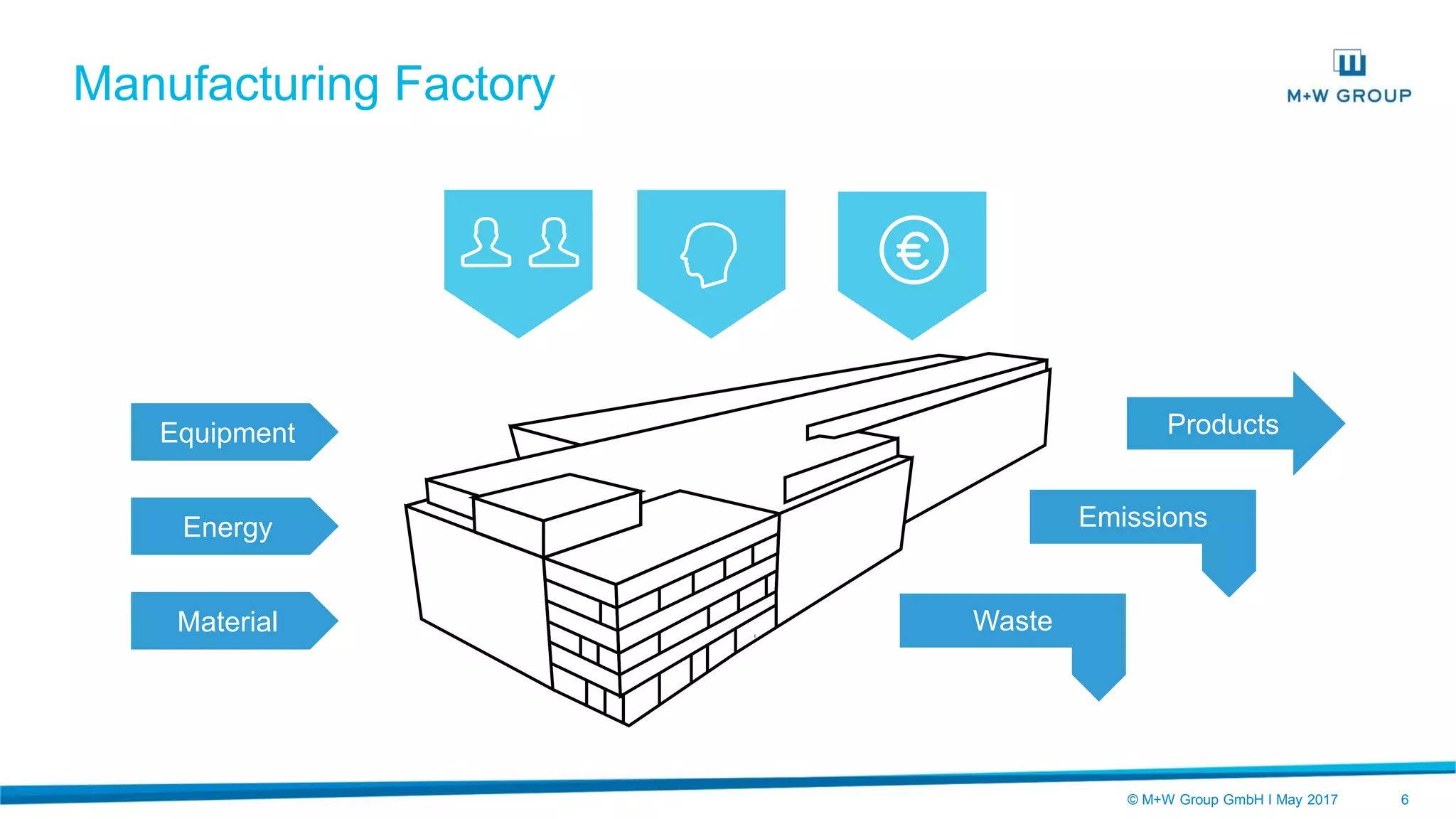

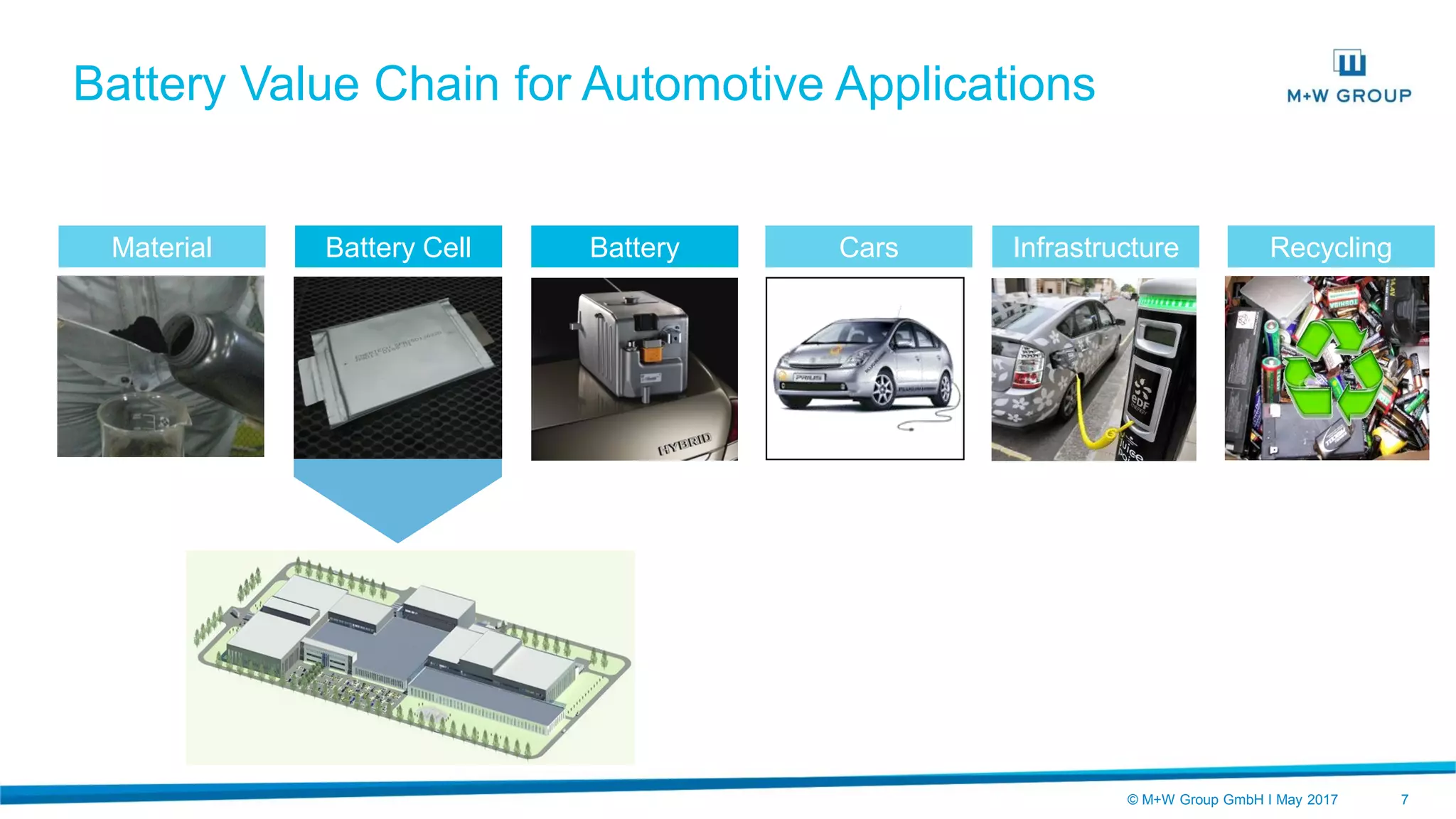

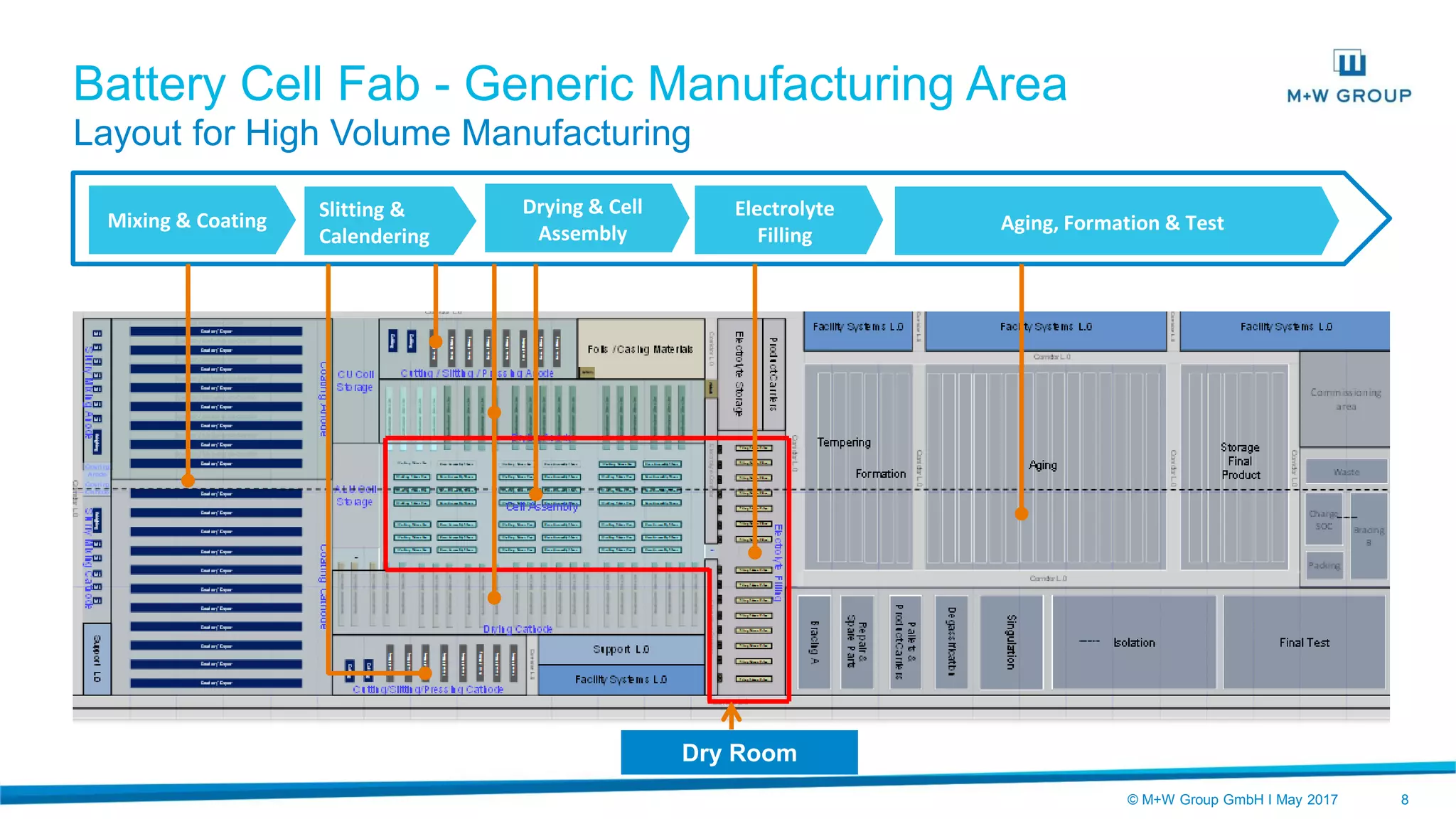

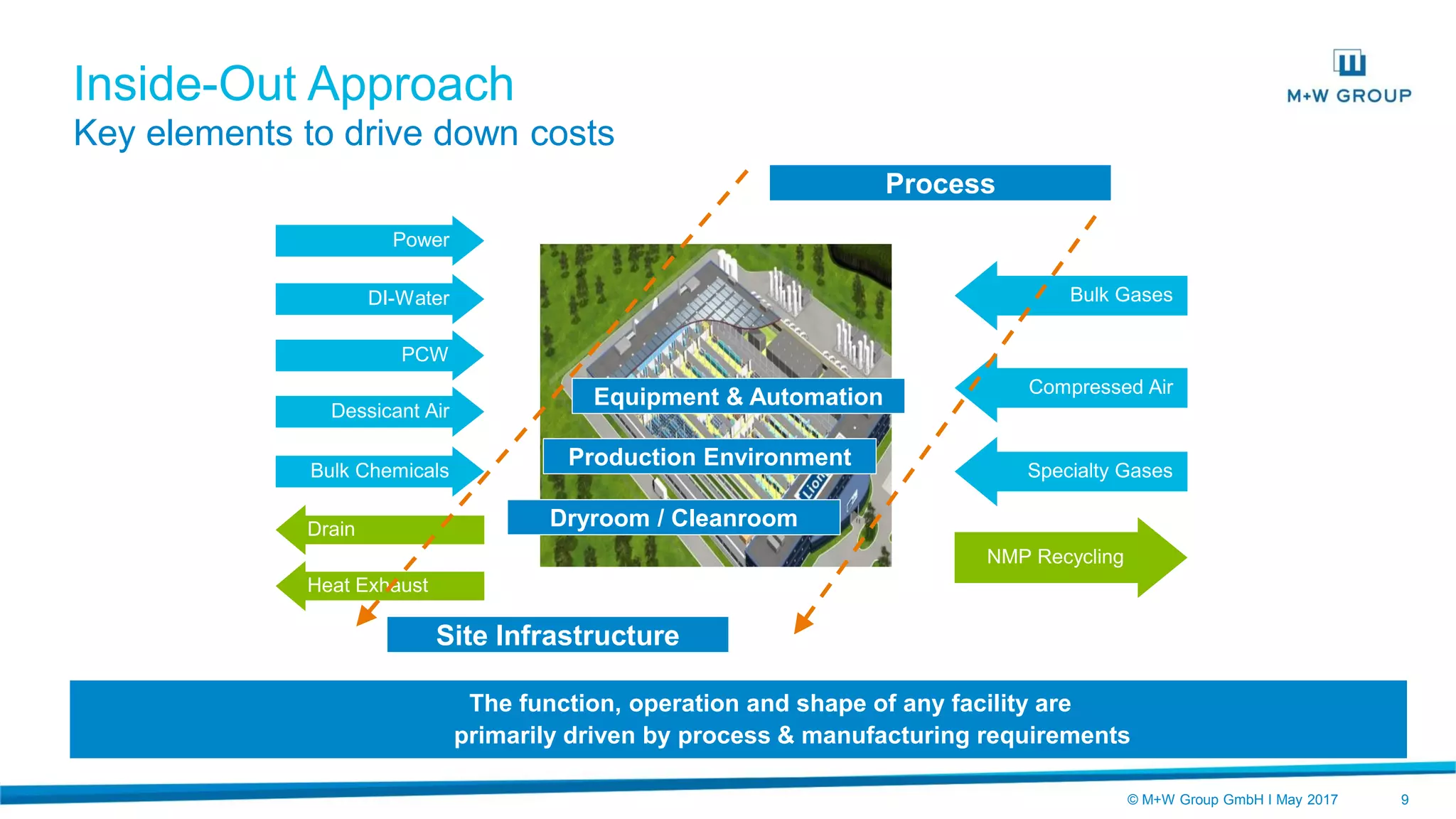

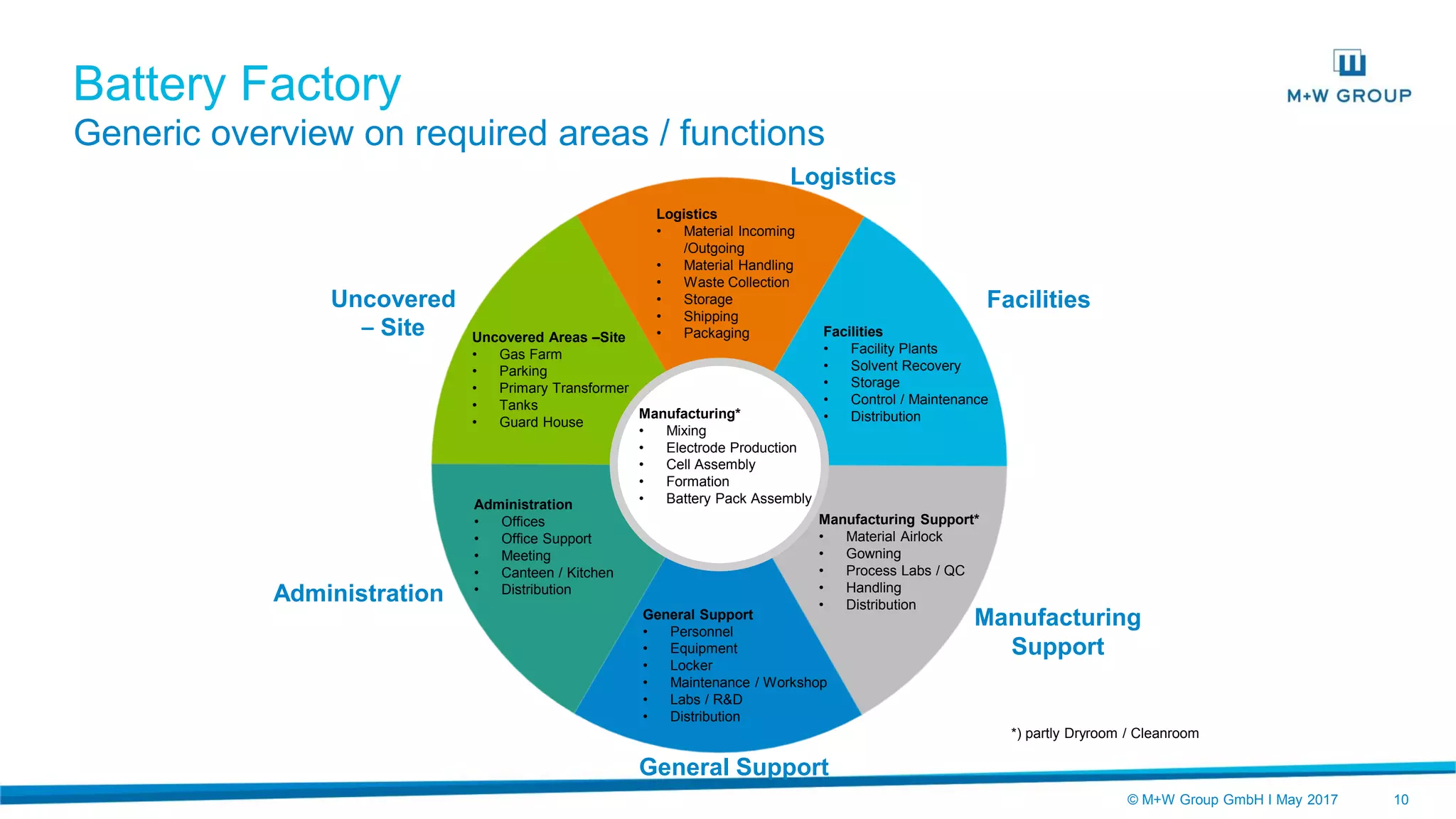

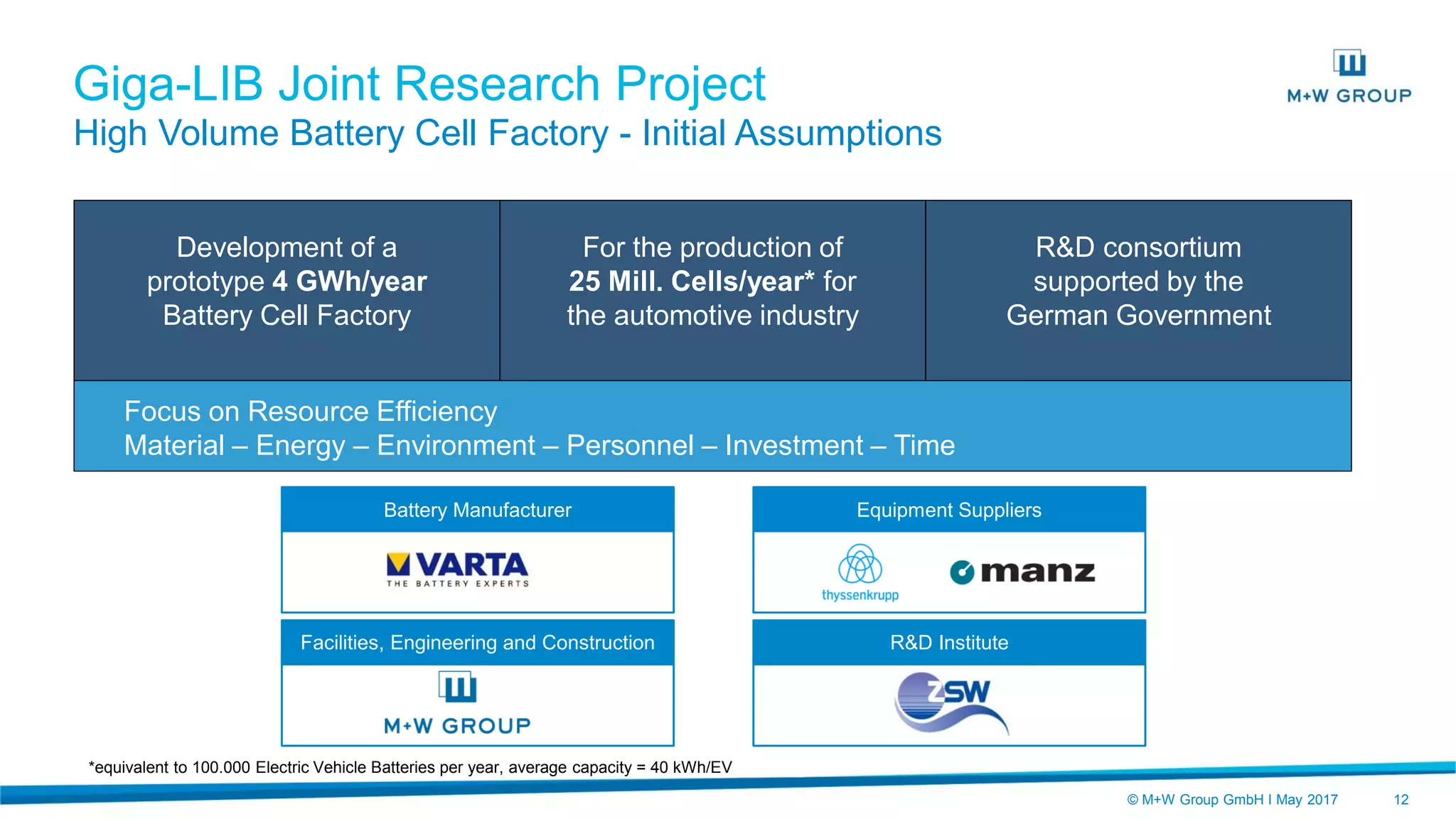

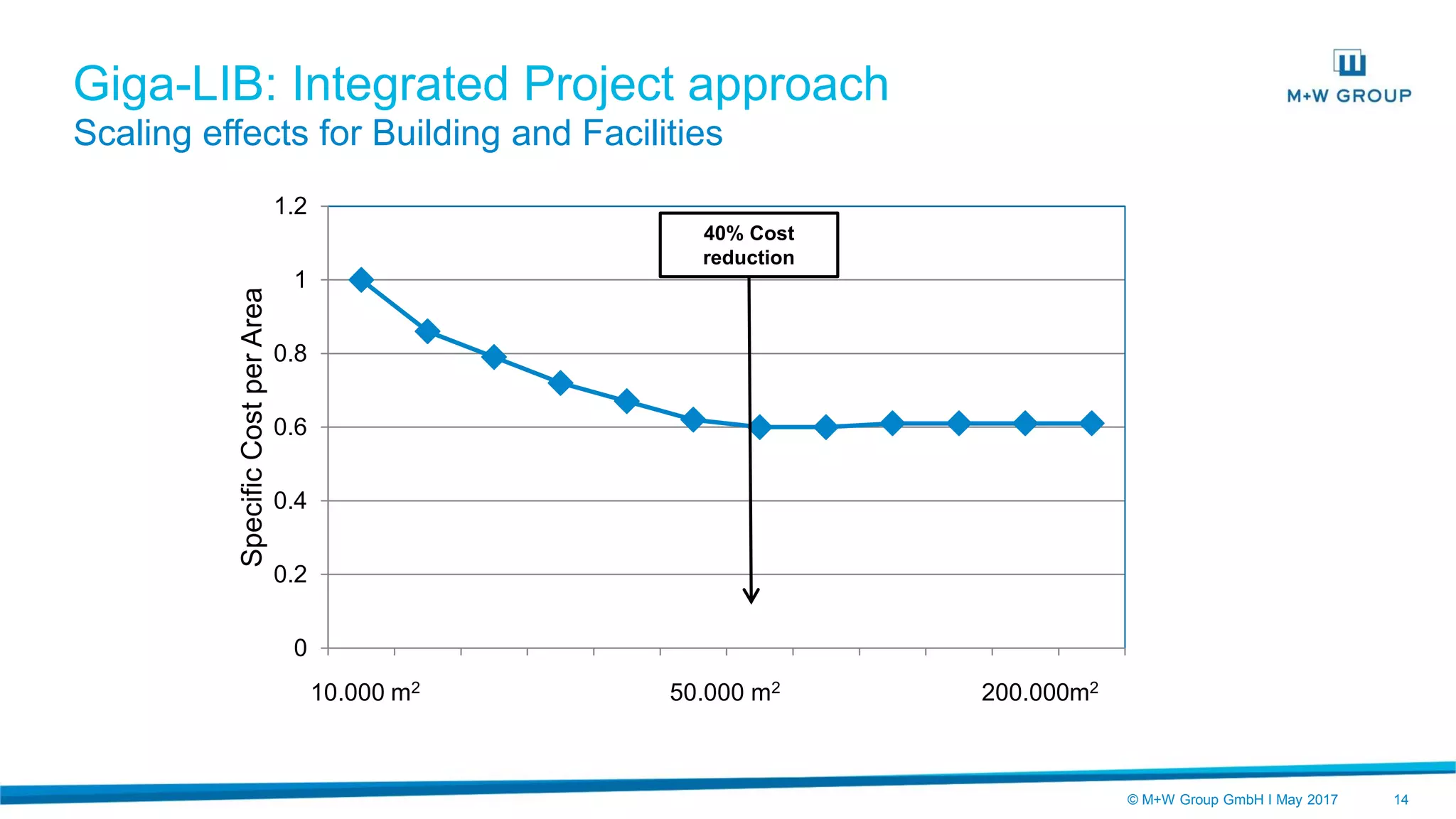

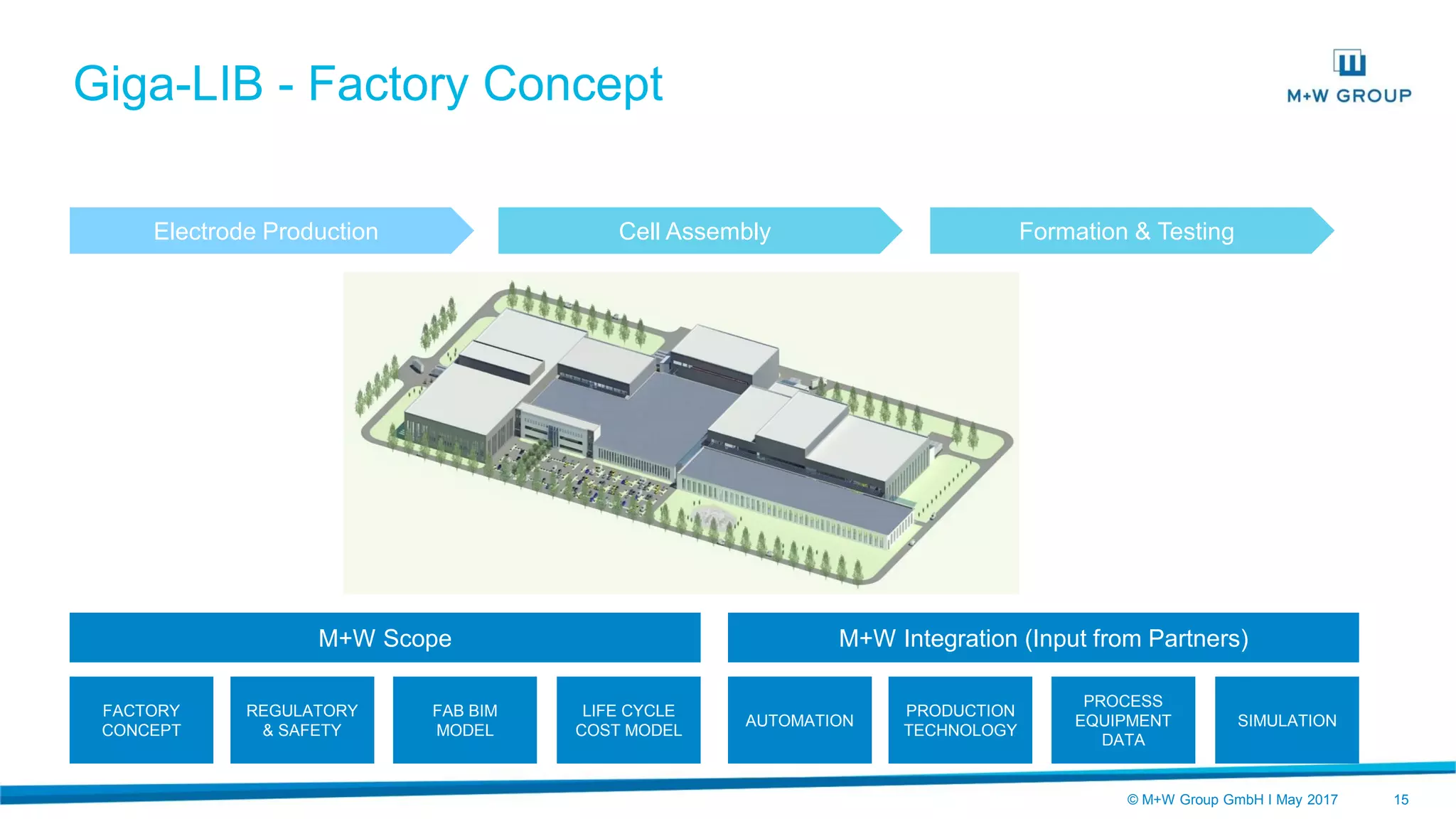

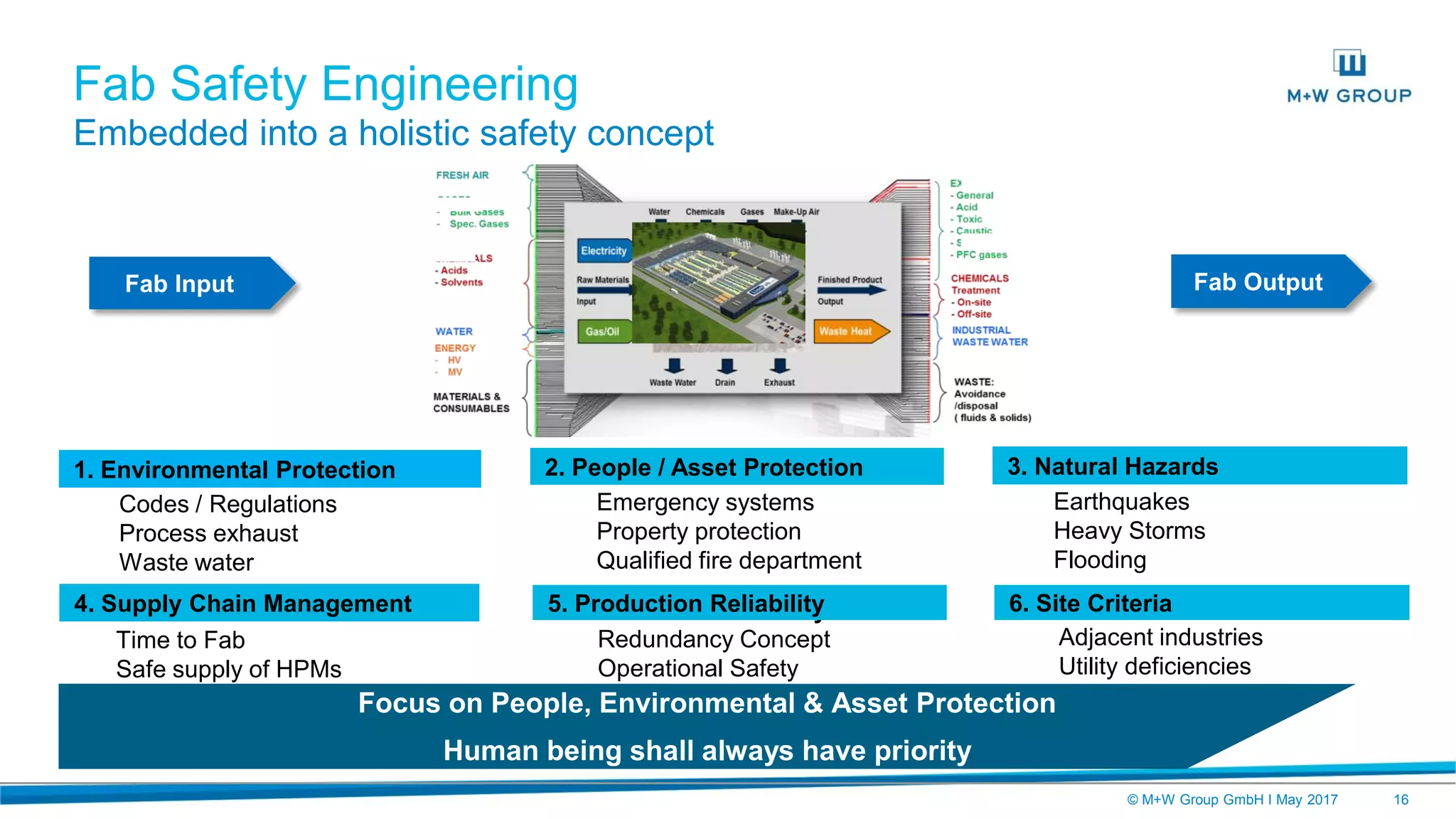

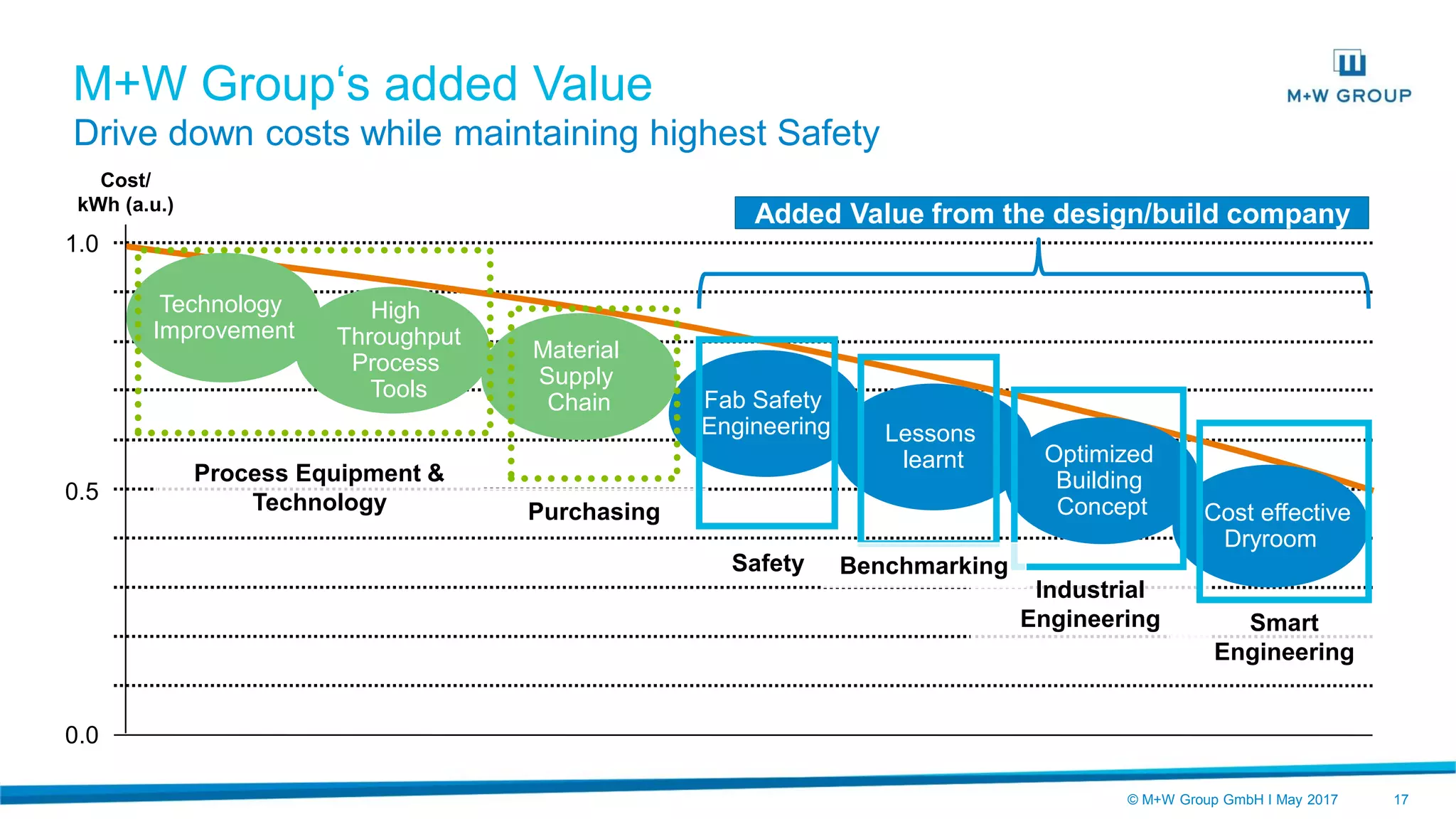

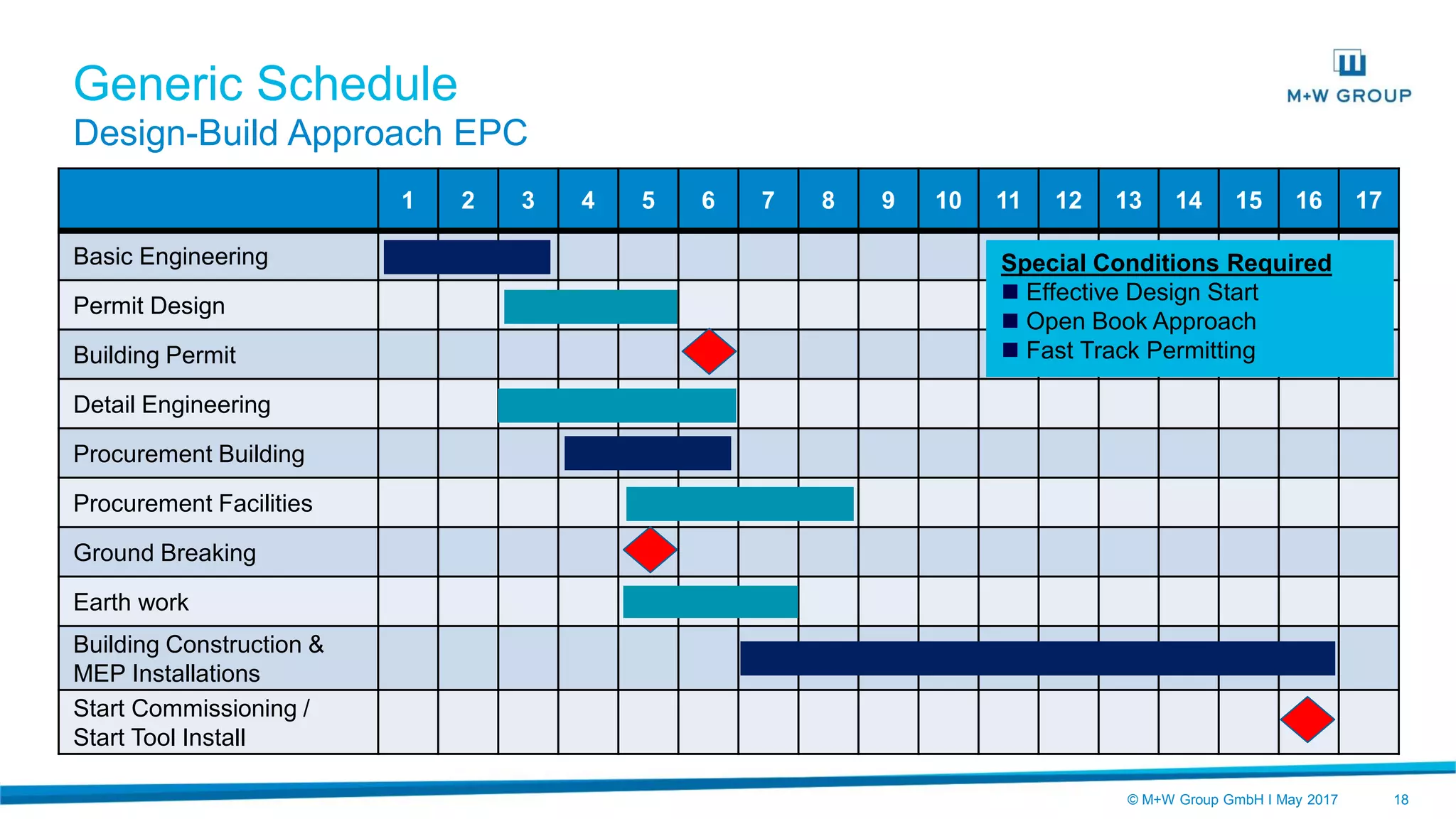

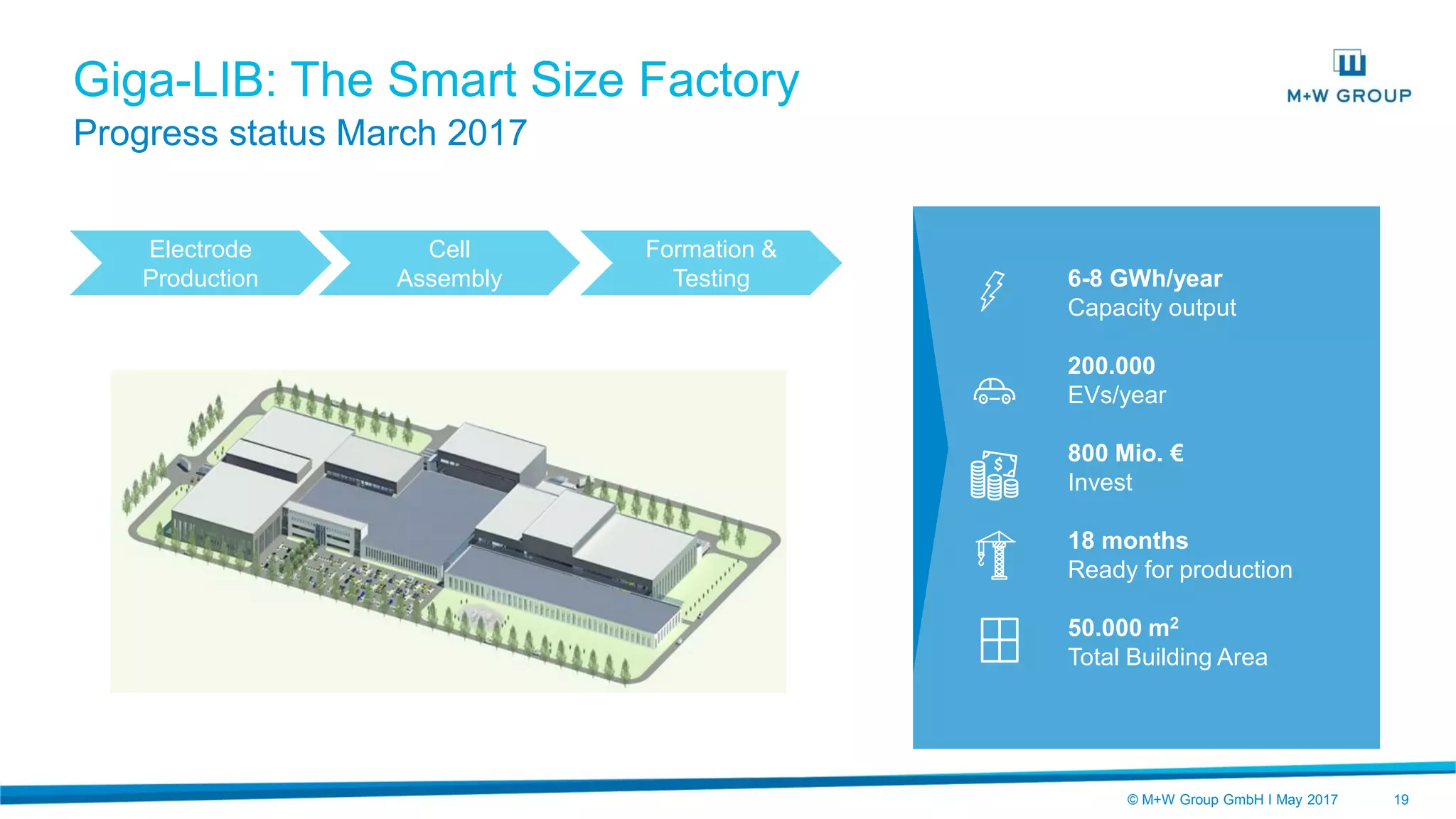

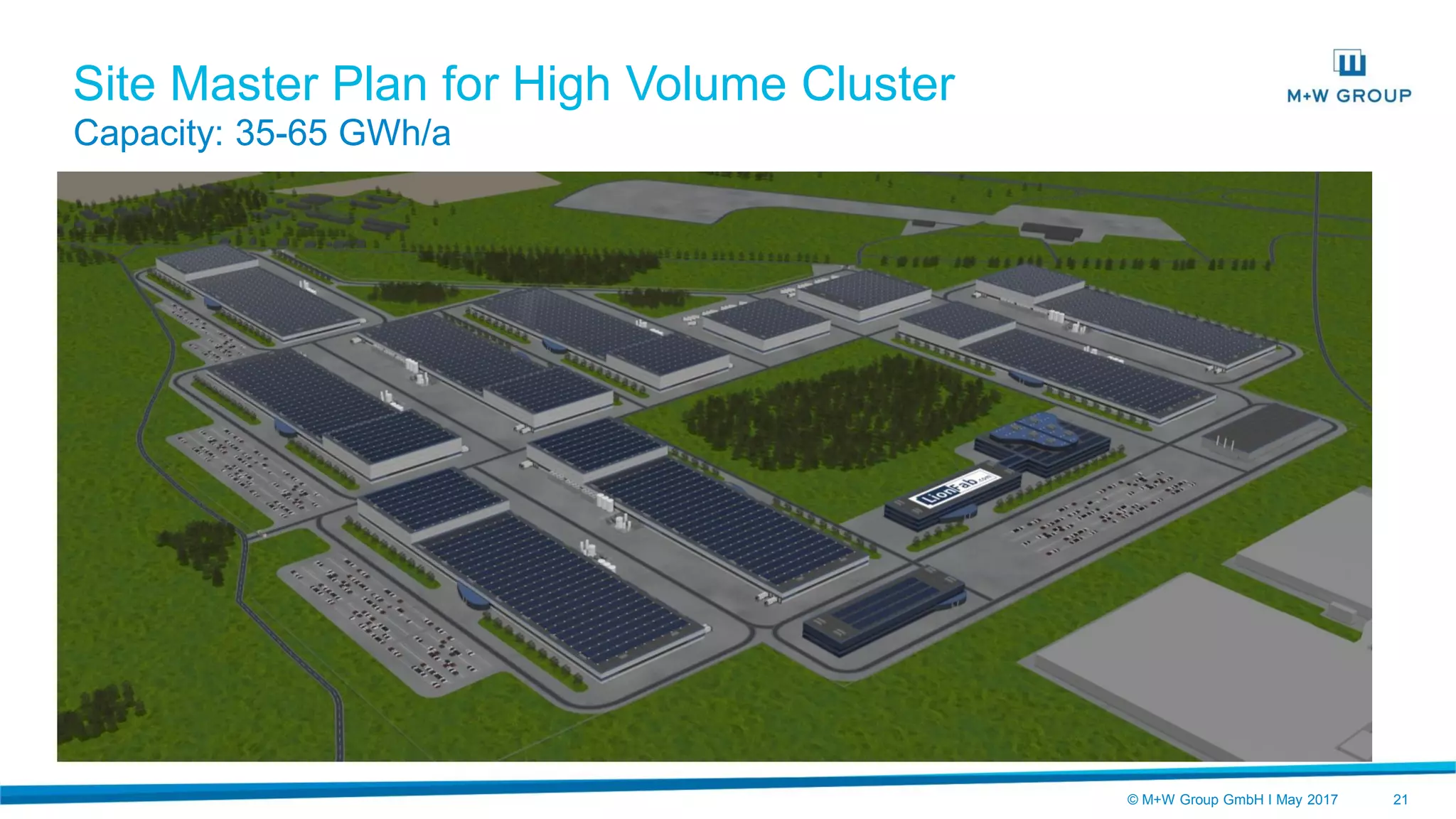

The document outlines the development of a smart size battery cell factory project in Munich aimed at producing high volume battery cells for the automotive industry with a capacity of 6-8 GWh/year. It highlights the importance of sustainability, resource efficiency, and cost reduction through an integrated project approach involving leading German high-tech companies. The initiative is part of the growing demand for lithium-ion batteries in various applications and emphasizes safety and advanced logistics in its factory design.