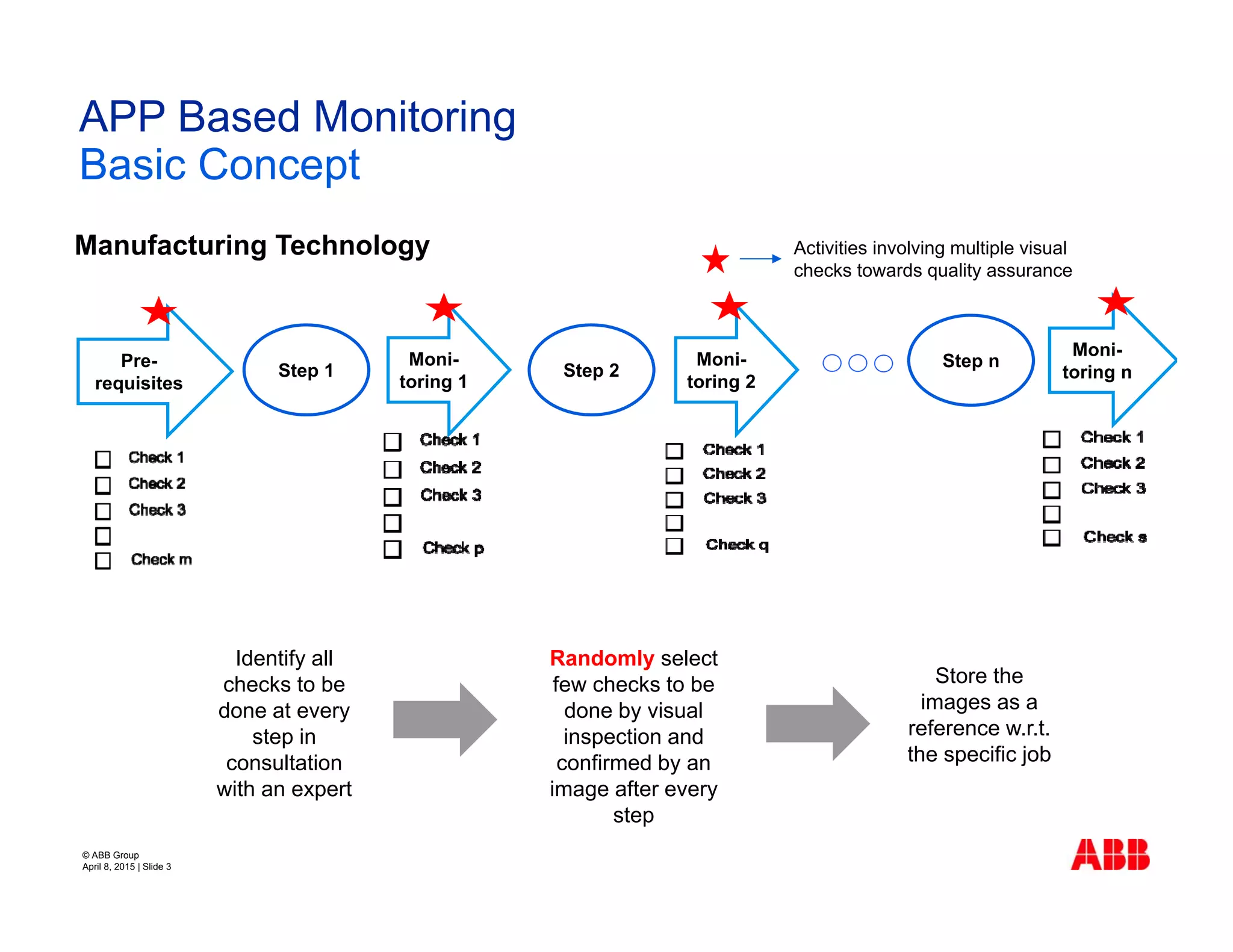

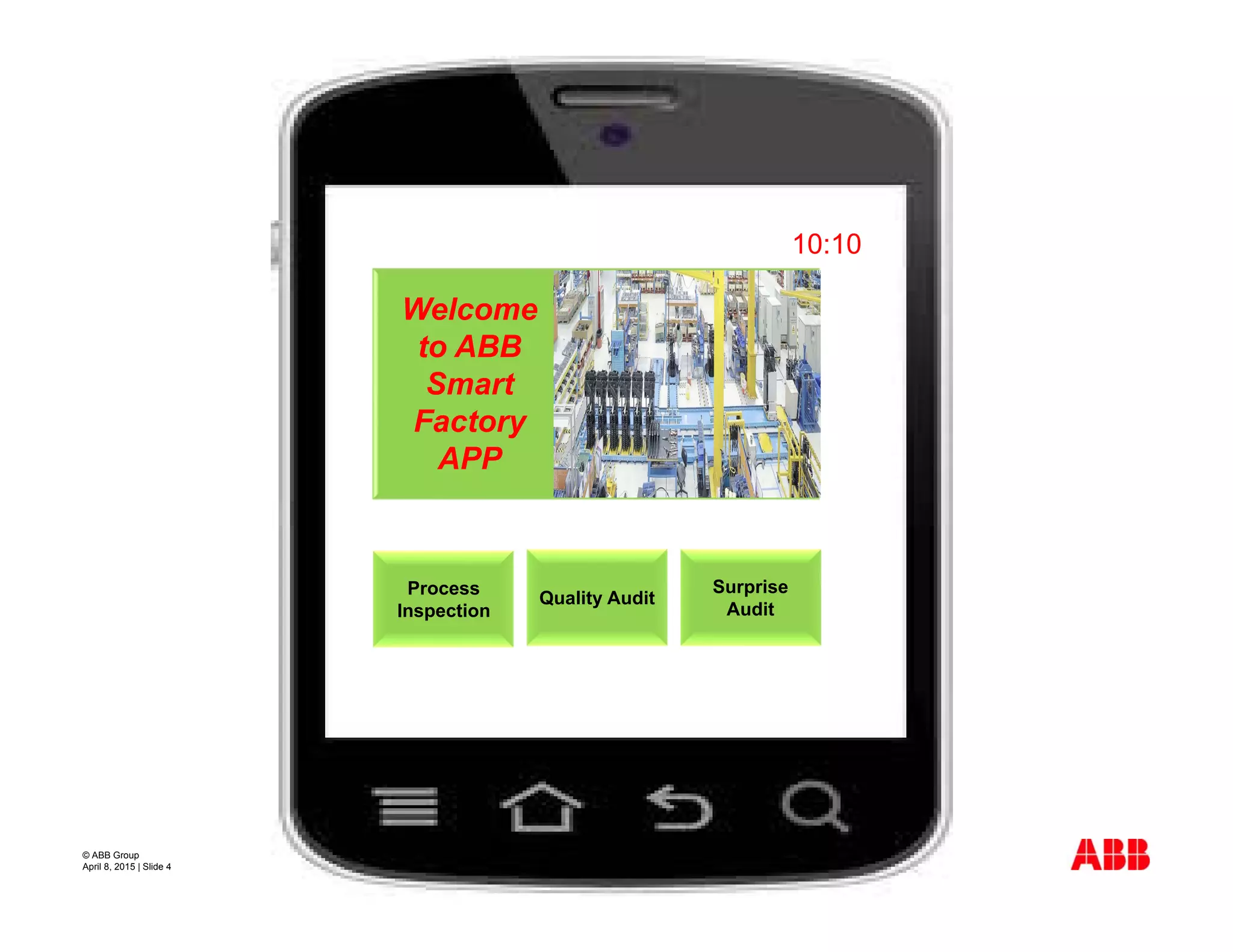

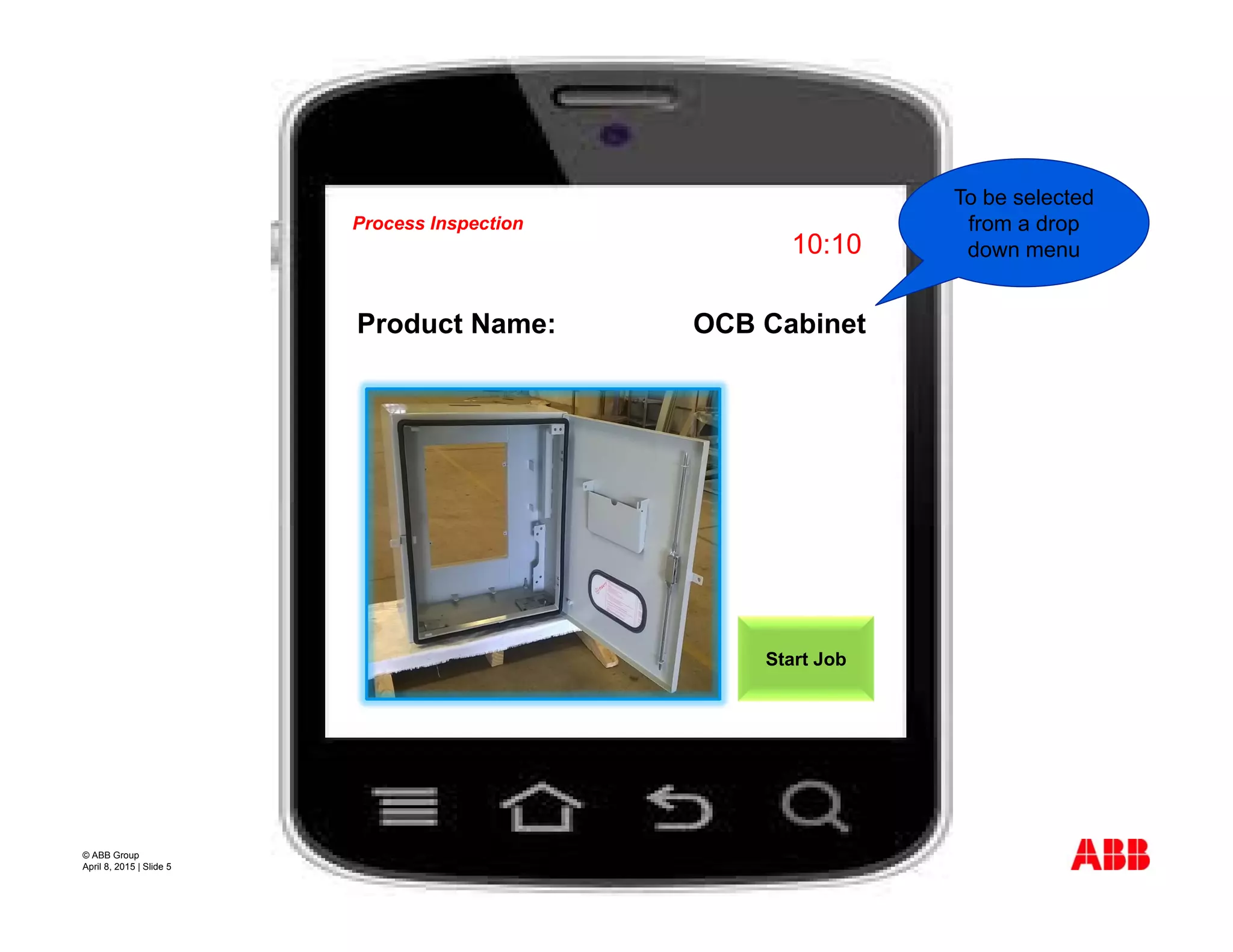

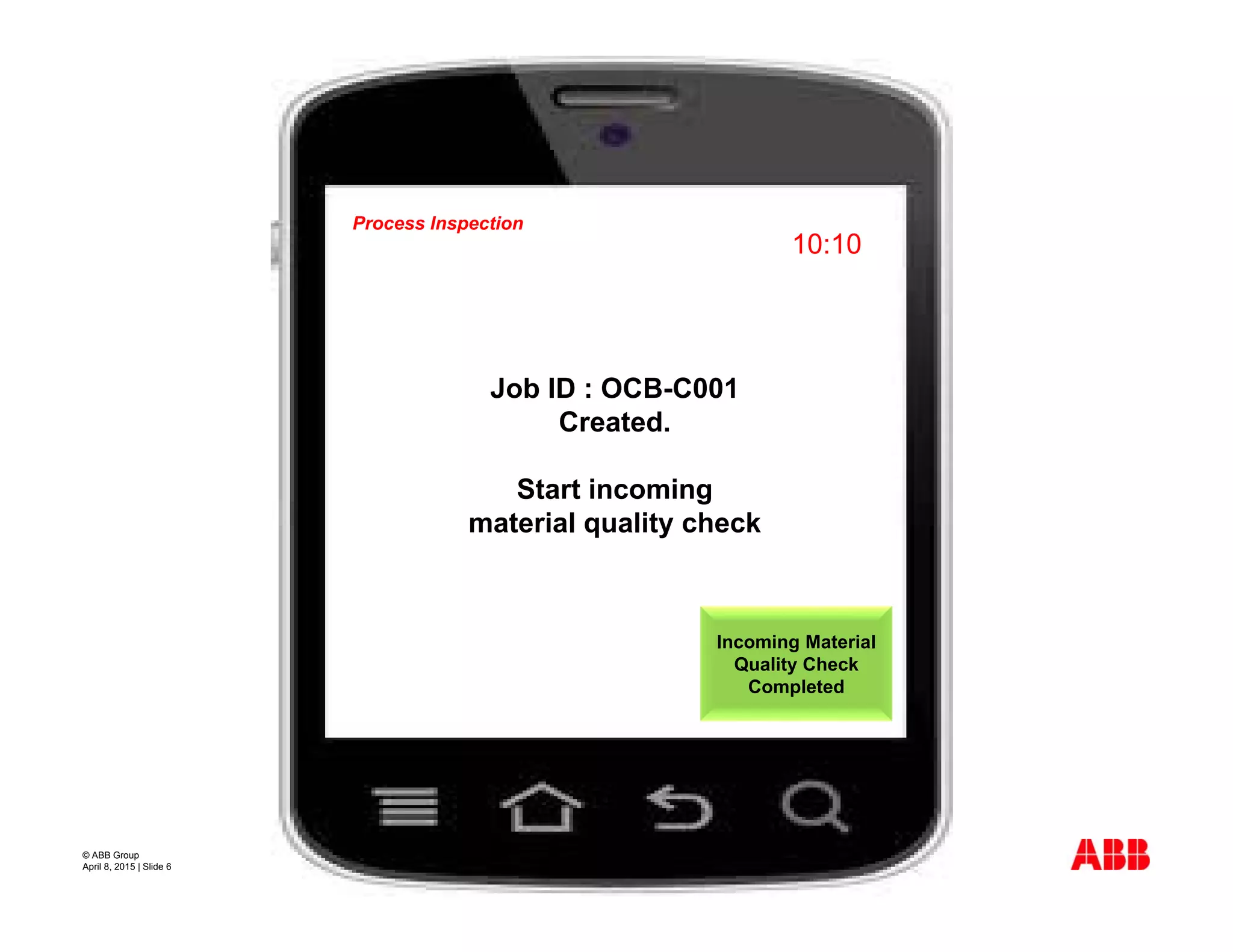

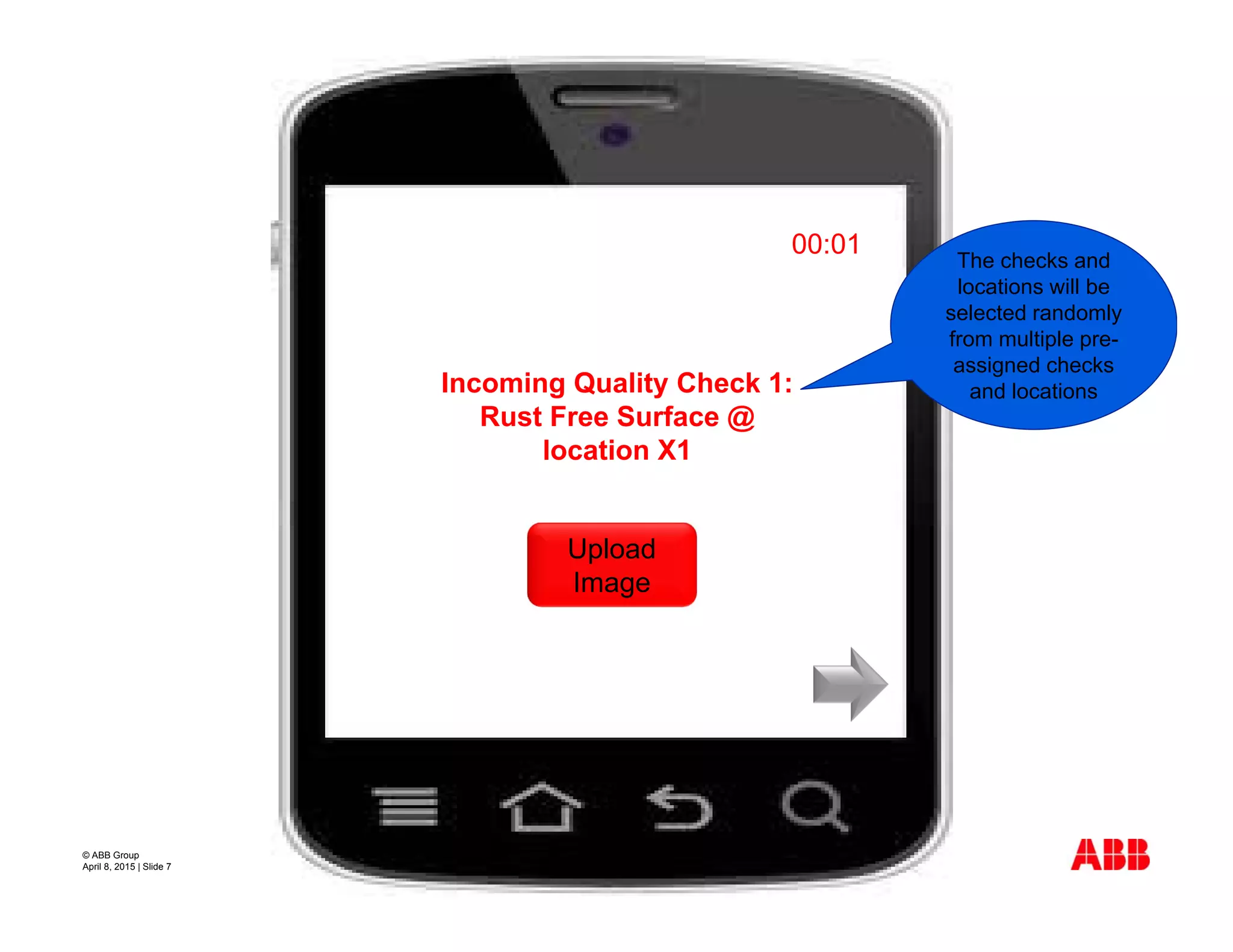

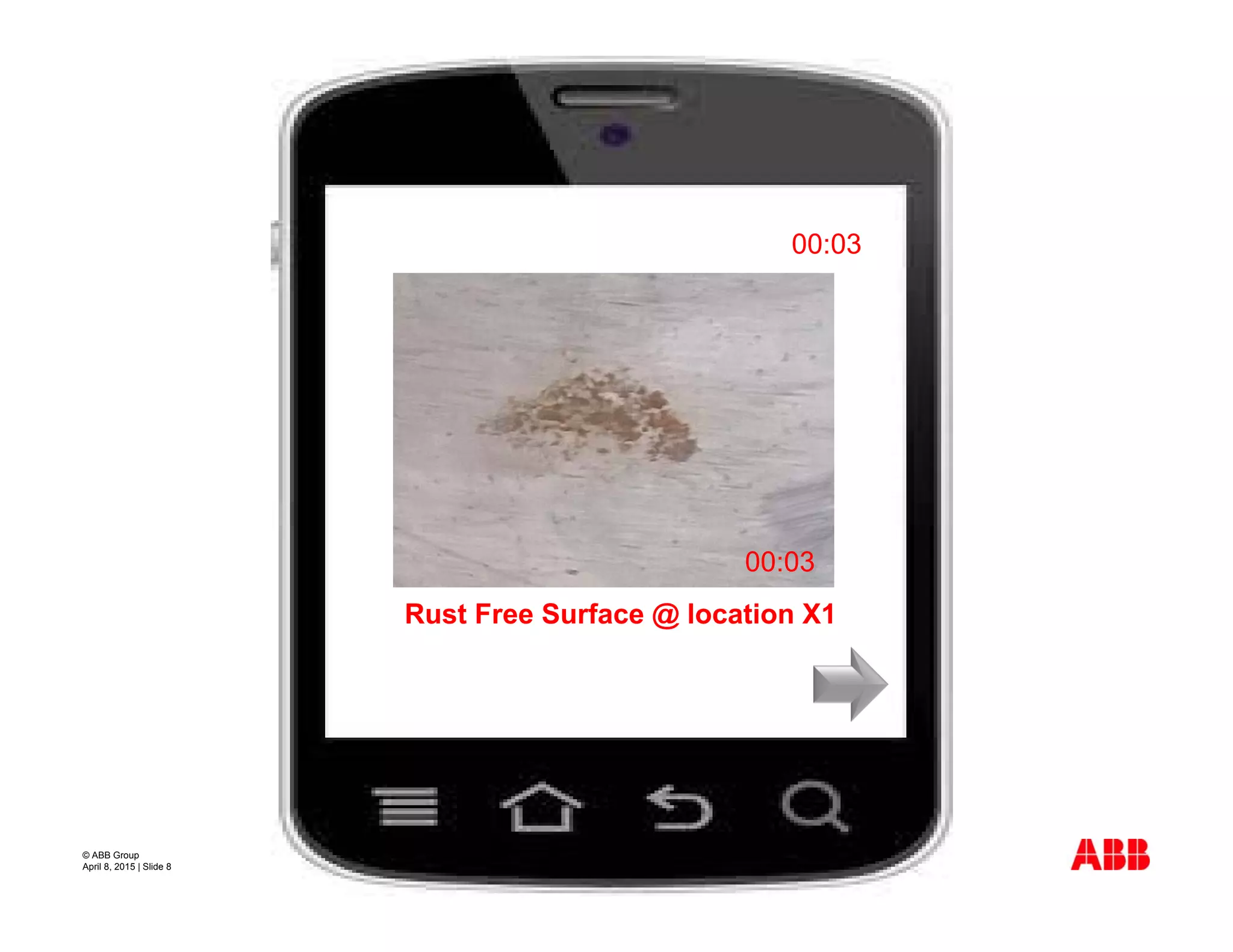

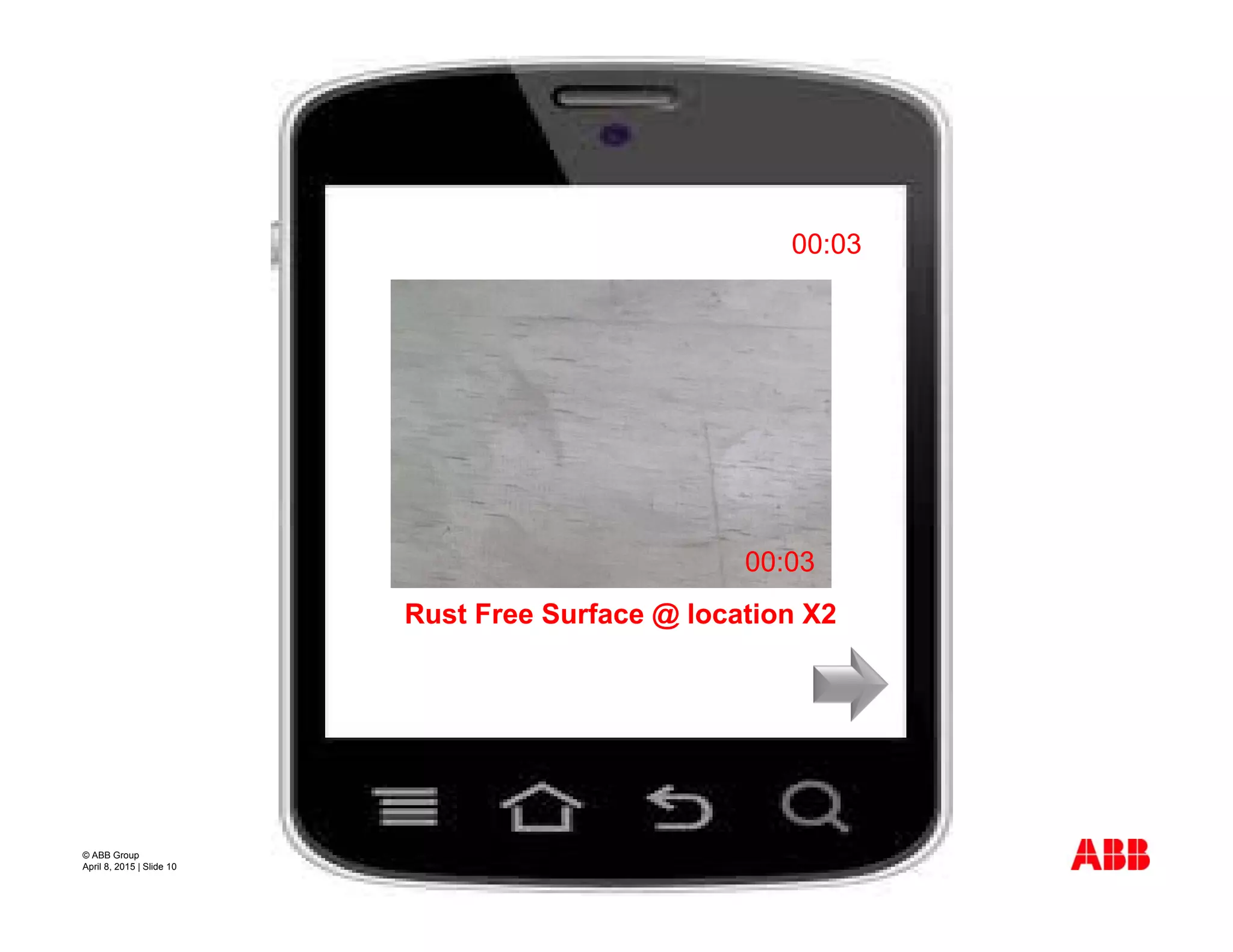

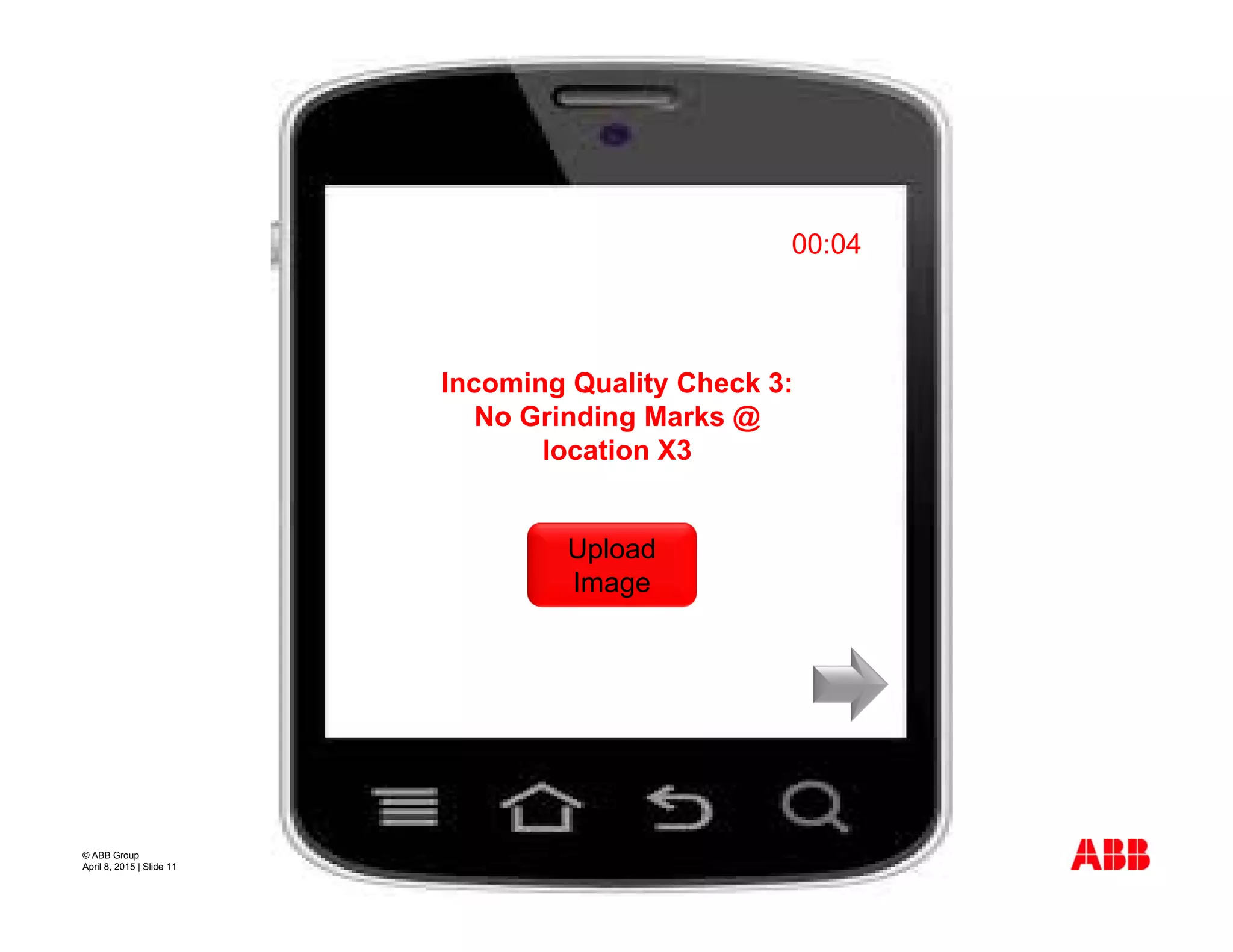

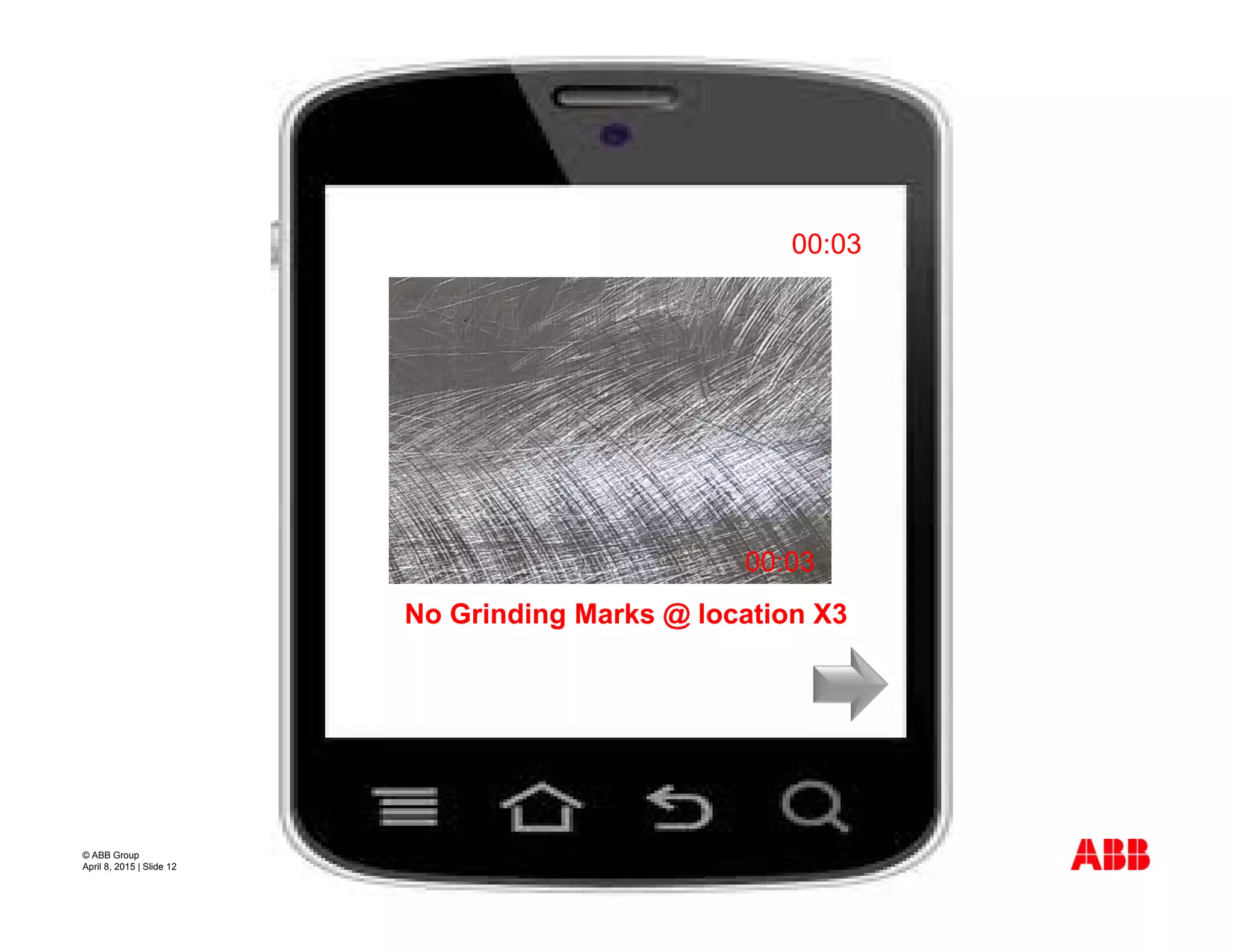

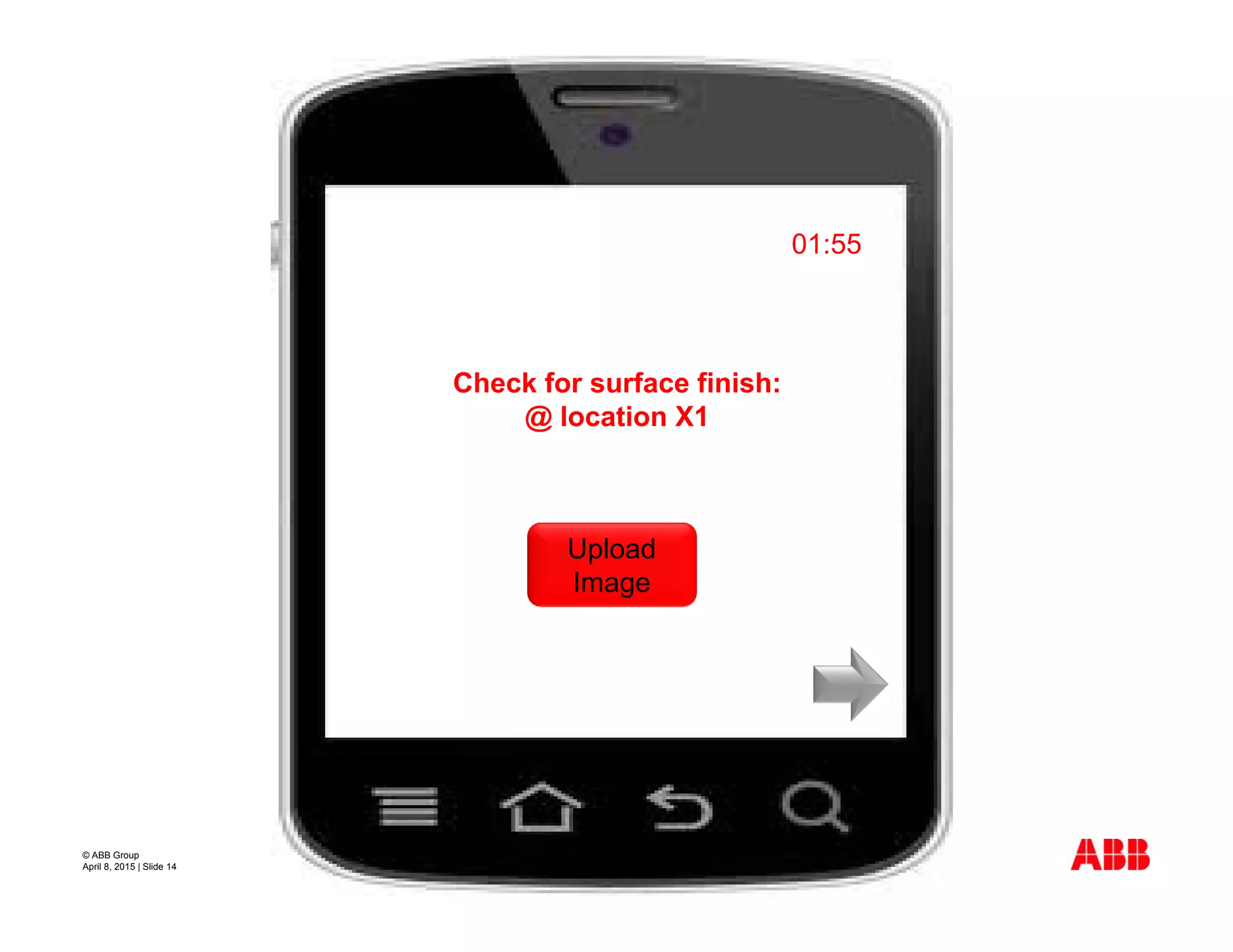

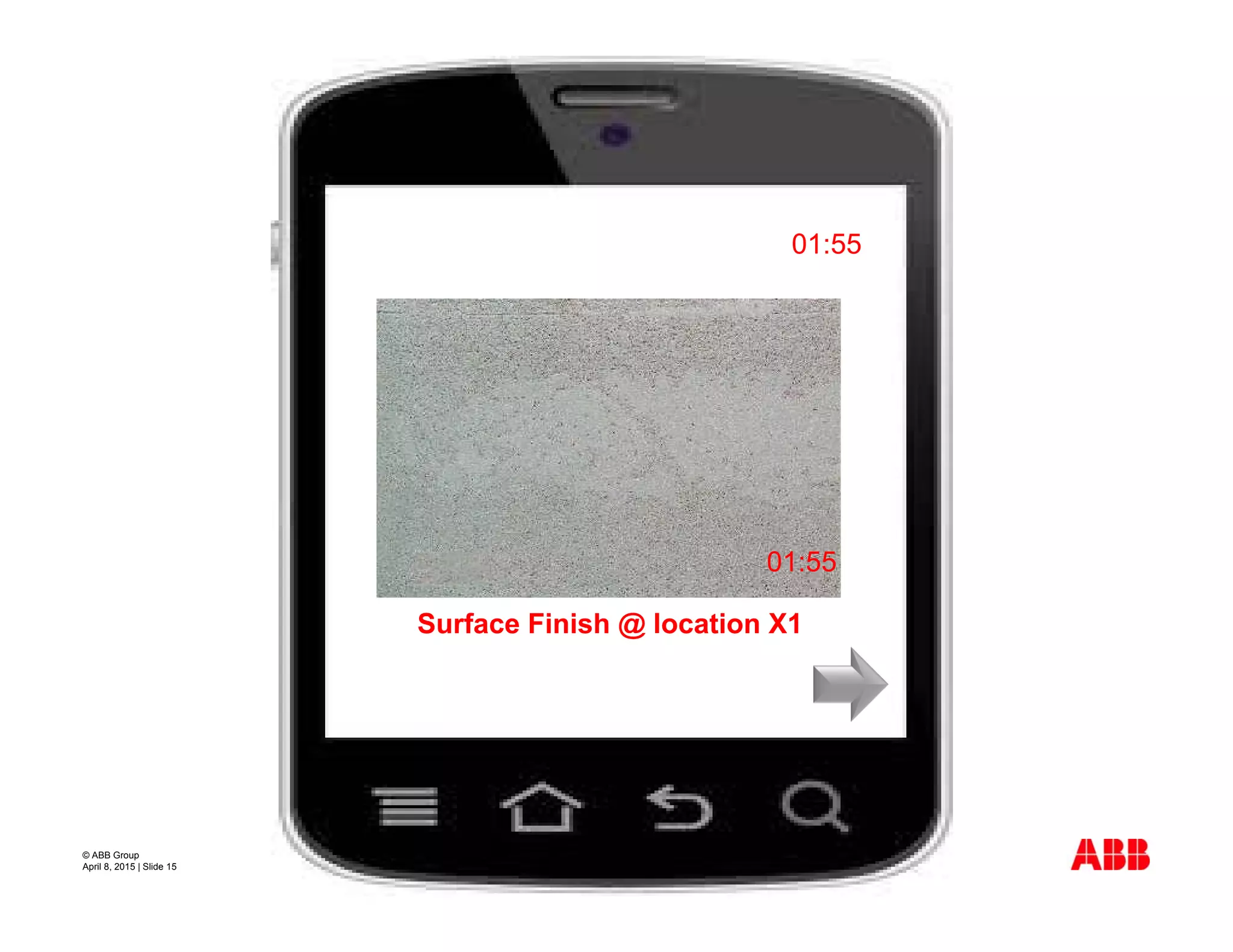

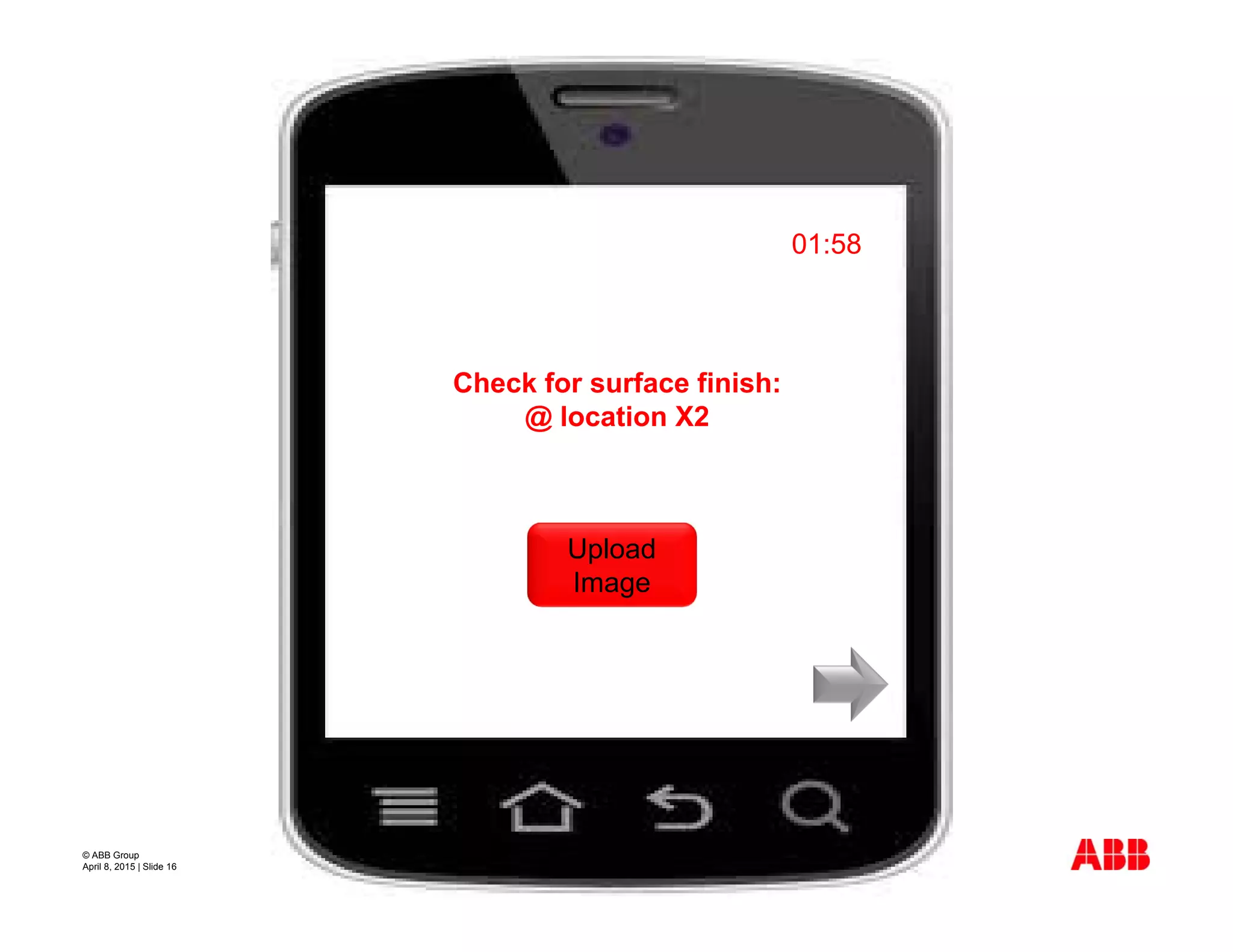

The document discusses the development of an app-based monitoring system to improve quality assurance in manufacturing. It notes that visual inspections currently make up 90% of quality checks but are inefficient. The proposed system would use an app to randomly select visual checks at different steps, upload images for verification, and store them for future reference to create an easy and low-cost quality monitoring solution. Screenshots provide an example of how the app would guide users through recording checks during a sample manufacturing process.