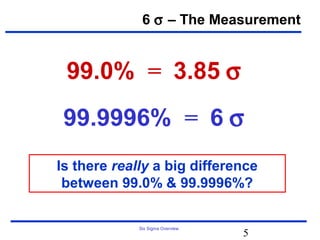

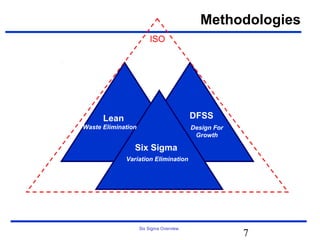

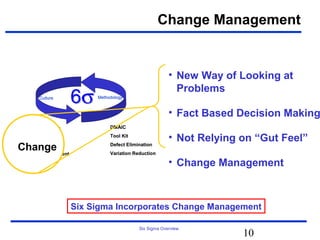

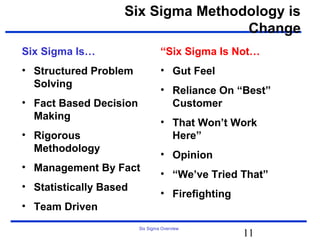

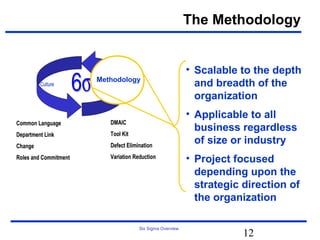

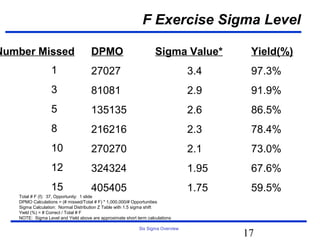

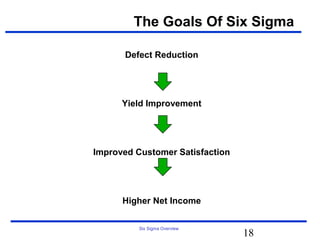

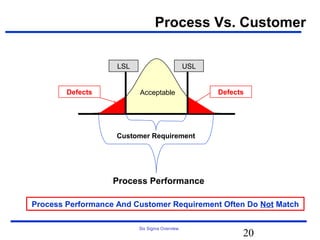

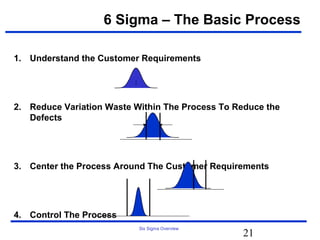

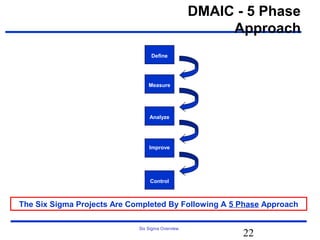

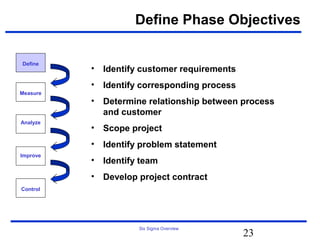

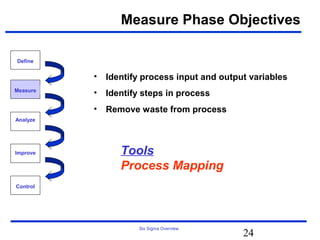

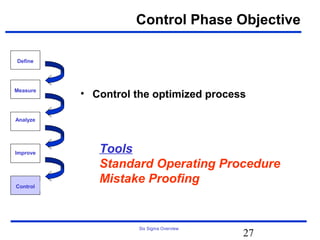

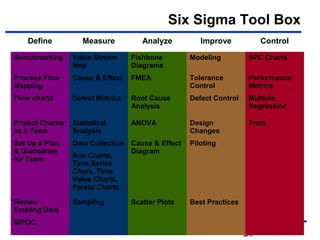

Six Sigma aims to reduce defects and variation in processes. It uses a data-driven methodology called DMAIC (Define, Measure, Analyze, Improve, Control) to systematically identify and remove causes of defects and errors. This helps processes meet customer requirements and improve outcomes like quality, customer satisfaction, and profitability. The goal of Six Sigma is to work towards achieving no more than 3.4 defects per million opportunities. This requires understanding customer needs and using tools and techniques to center processes around those needs while minimizing waste and variation.