This document provides an overview of Six Sigma, including:

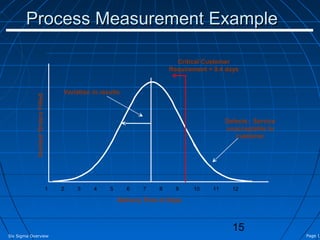

1) Six Sigma is a data-driven approach to improving processes by minimizing defects, with a goal of achieving near perfection. It was developed at Motorola to focus on customer requirements and identify the root causes of defects.

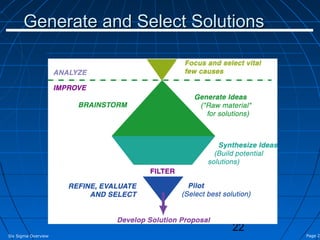

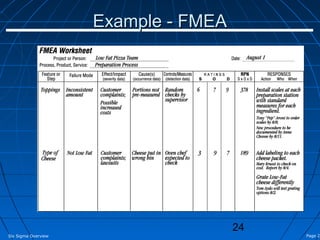

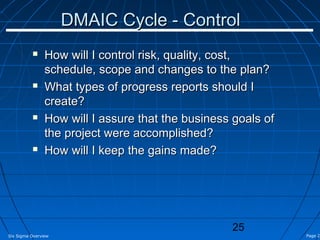

2) Six Sigma employs a DMAIC (Define, Measure, Analyze, Improve, Control) methodology to improve existing processes or a DMADV/DFSS (Define, Measure, Analyze, Design, Verify) methodology to develop new processes.

3) Six Sigma projects are led by Black Belts and Master Black Belts who are certified in the methodology. The Define stage establishes the project goals and scope