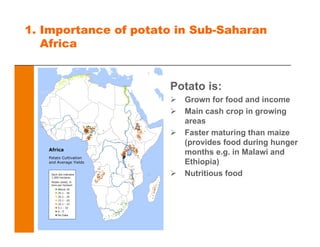

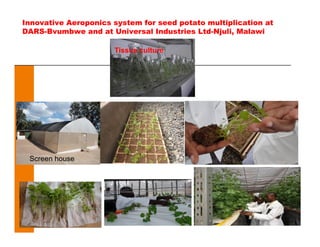

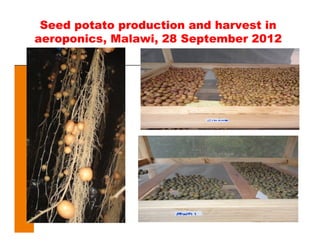

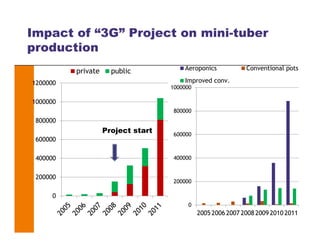

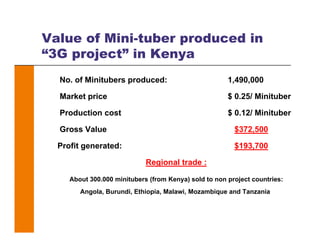

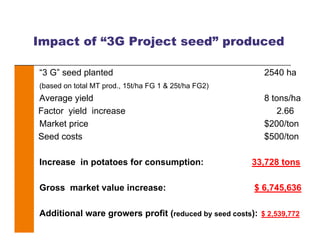

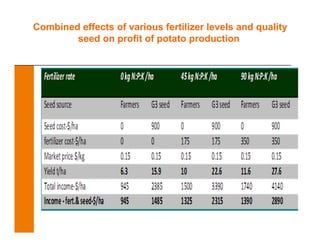

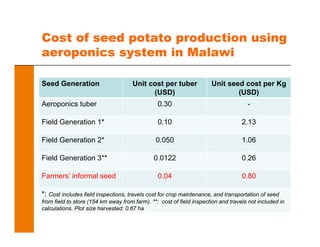

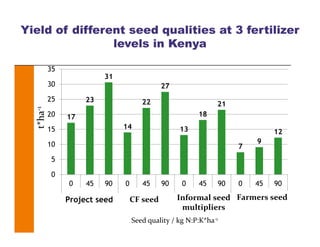

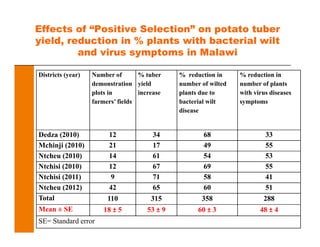

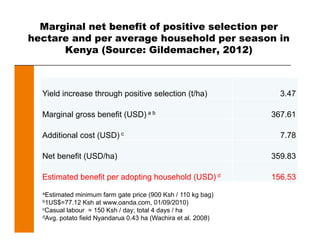

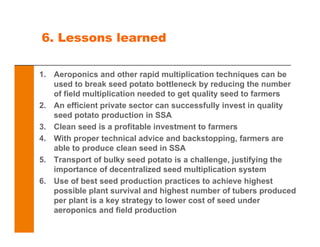

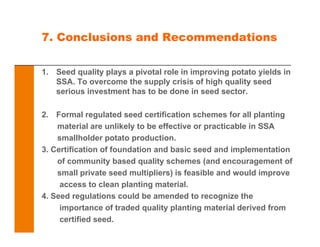

This document summarizes strategies to improve seed potato quality and supply in sub-Saharan Africa based on interventions in five countries. It discusses the importance of potatoes, the problem of lack of quality seed, and objectives to increase availability of affordable quality seed. Strategies used rapid multiplication techniques like aeroponics to produce pre-basic seed, which was then multiplied through specialized seed farms and smallholder farmers. Results showed increased seed production and higher yields. Lessons highlighted the role of clean seed and public-private partnerships, and recommendations called for investment in the seed sector and quality declared community schemes to improve access to quality planting material.