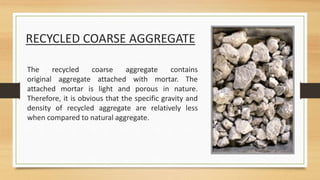

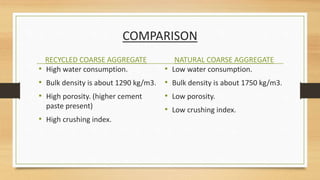

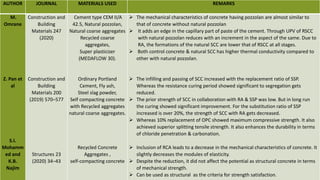

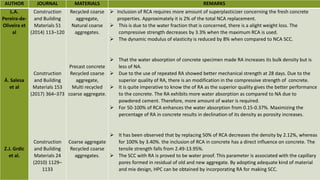

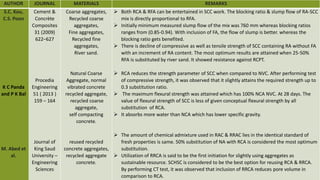

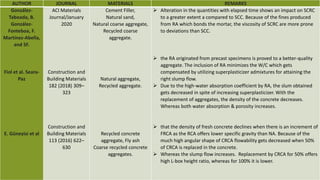

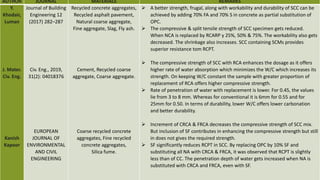

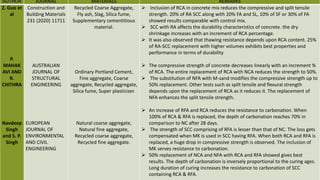

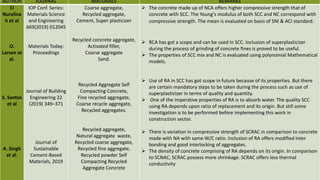

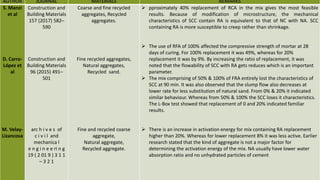

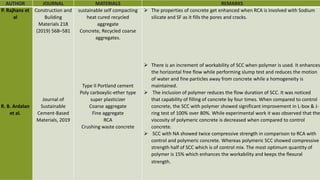

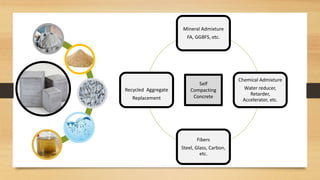

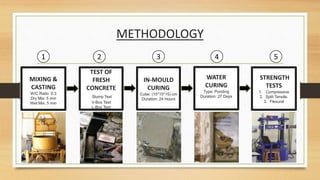

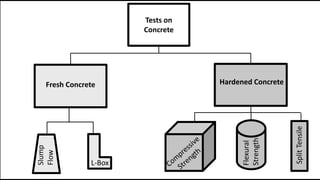

The document discusses self-compacting concrete (SCC) that utilizes recycled coarse aggregates, highlighting methodologies, advantages, limitations, and performance characteristics. It presents comparative assessments between SCC, normal concrete, and the properties of recycled versus natural aggregates, noting the impact on mechanical strength and durability. Key findings include the lower compressive and tensile strengths associated with higher recycled aggregate content, while still meeting performance standards for structural application.