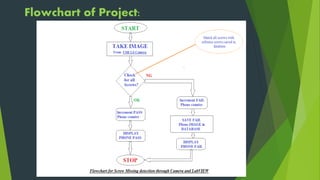

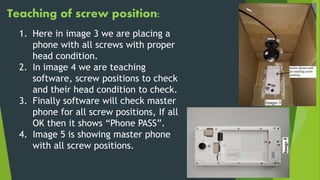

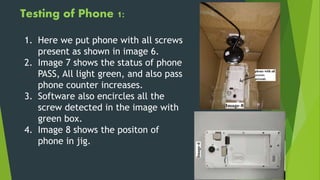

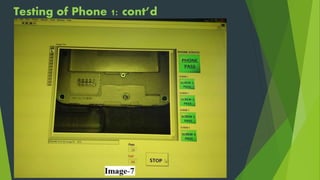

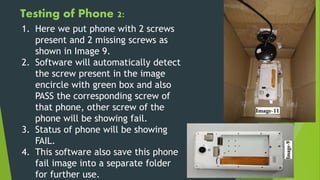

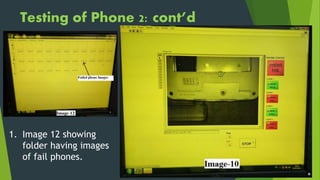

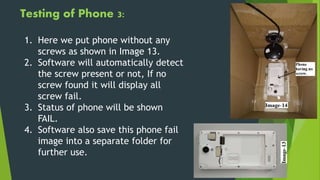

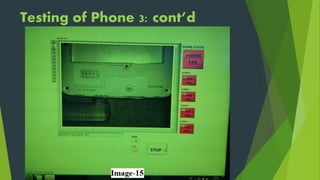

This document summarizes a project to design a system using a camera and LabVIEW to detect missing screws on phones during production. The system teaches itself the correct screw positions and detects any missing or improperly installed screws. It can check for issues during assembly, packaging, or other quality checks. When it finds a problem, it flags the phone as failing, circles any missing screws in red and saves the image for records. It aims to help operators catch defects and update performance data. Future upgrades could include operator login records, model-specific data storage on a server, and issue reporting via text files.