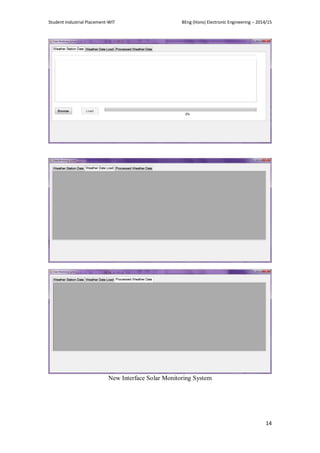

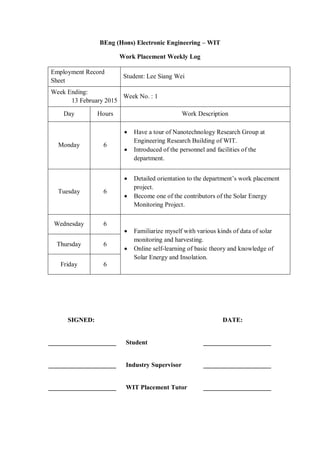

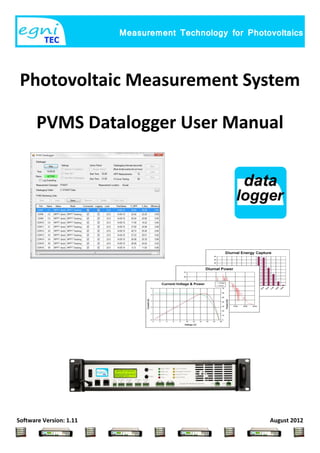

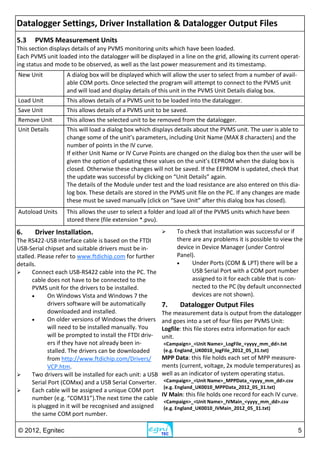

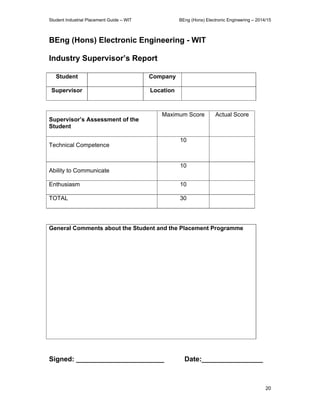

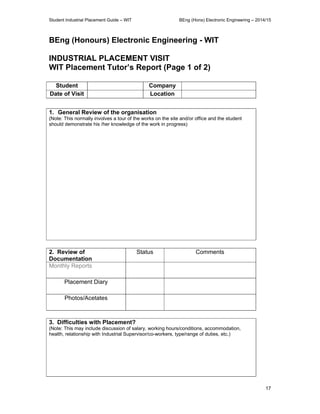

This document is a work placement report submitted by Lee Siang Wei, a student in the BEng (Hons) Electronic Engineering program at Waterford Institute of Technology. During a 15-week placement in 2015, Lee worked as a research student in the Nanotechnology Research Group. Key responsibilities included programming work to troubleshoot errors in a Solar Monitoring System, analyzing solar data, and preparing performance reports on solar energy generation. The placement provided valuable practical experience in programming, data analysis, and working within an academic research group focused on photovoltaic technologies.