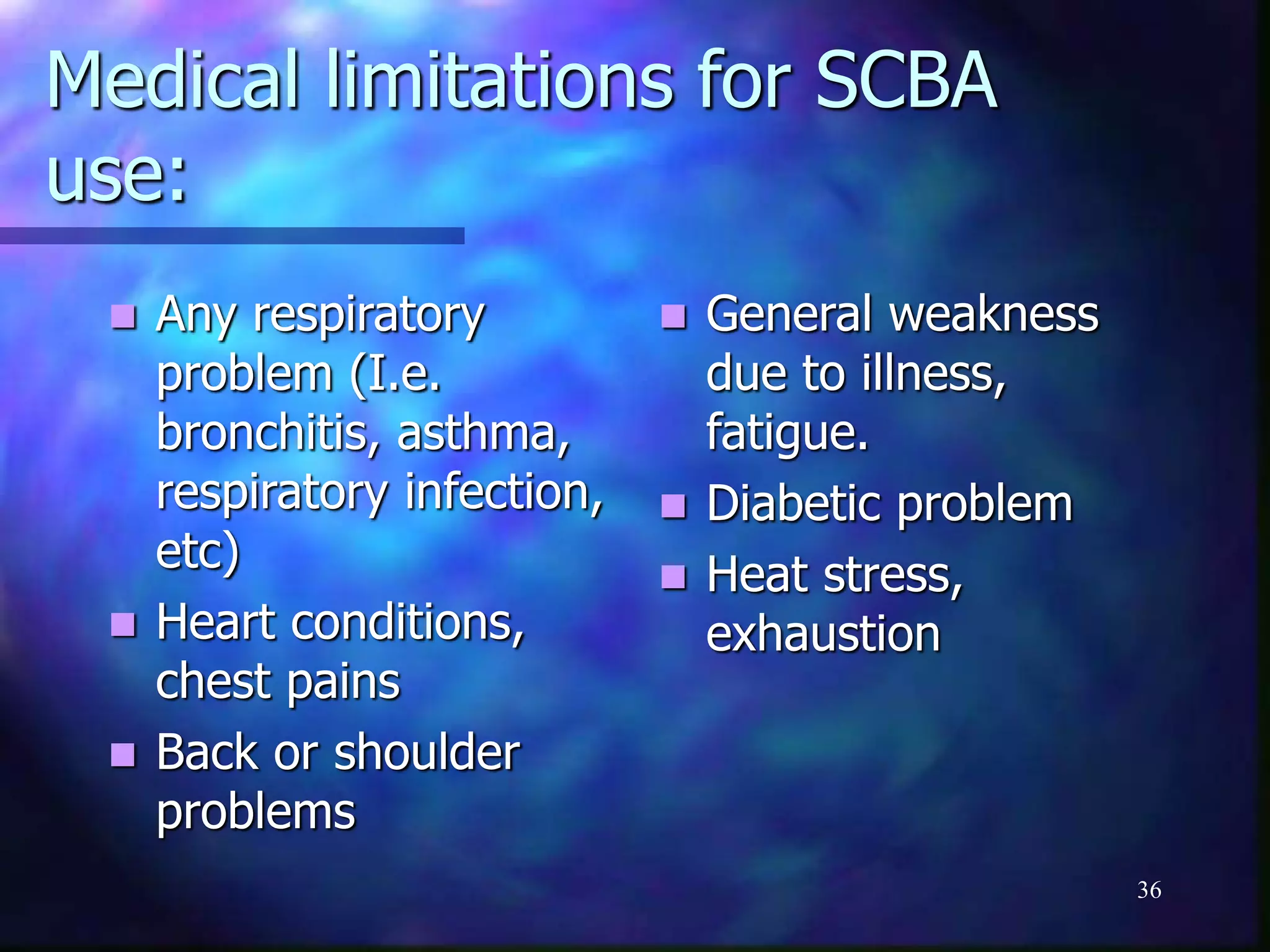

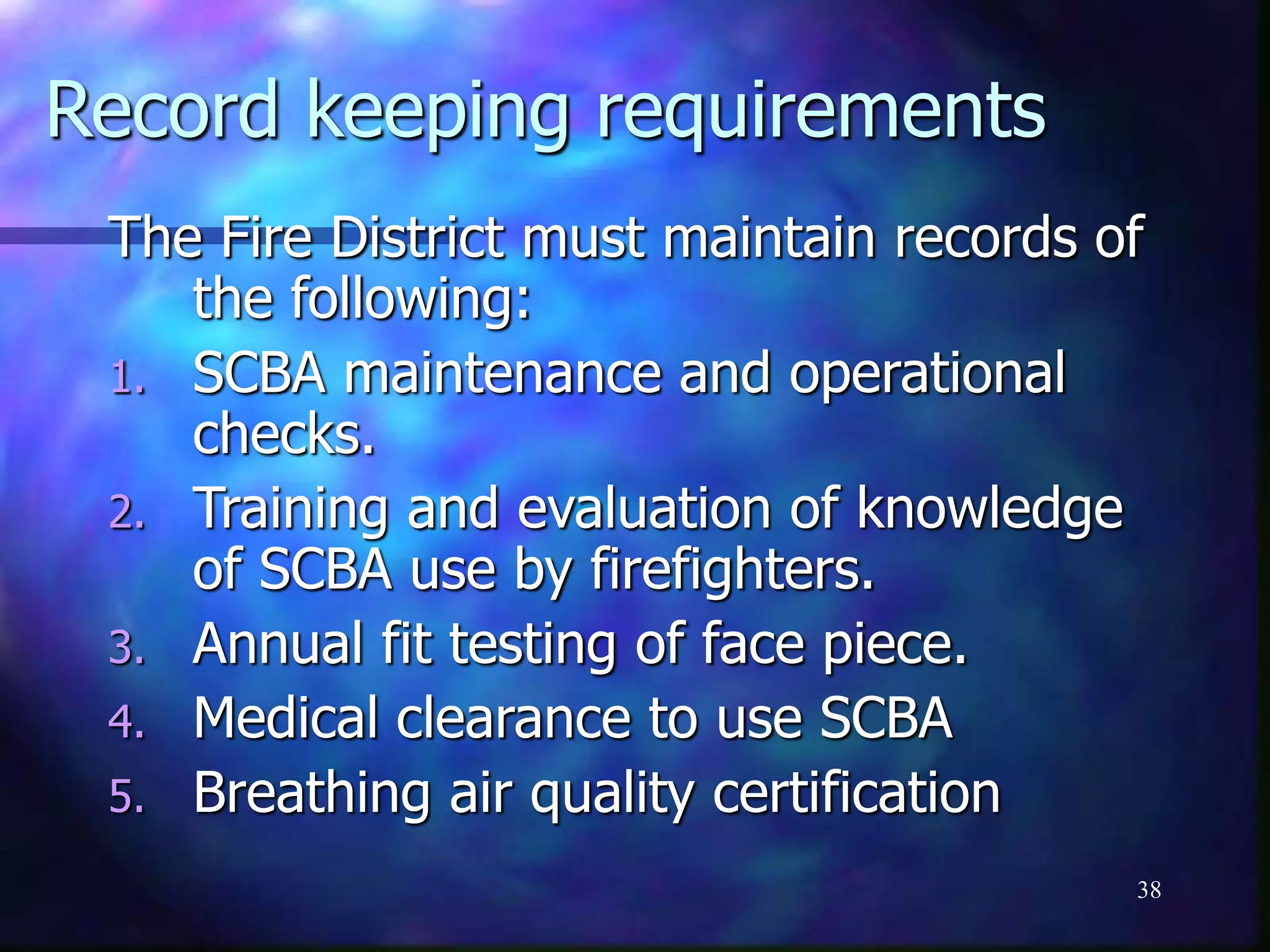

This document provides training on respiratory protection and the proper use of self-contained breathing apparatus (SCBA) for firefighters. It reviews why SCBA use is necessary to protect against smoke inhalation, proper donning and doffing procedures, emergency protocols, inspection, cleaning and maintenance. The objectives are to ensure firefighters understand OSHA standards, how to properly use SCBA equipment to stay safe, and demonstrate competency in donning, doffing, emergency procedures and equipment inspection.