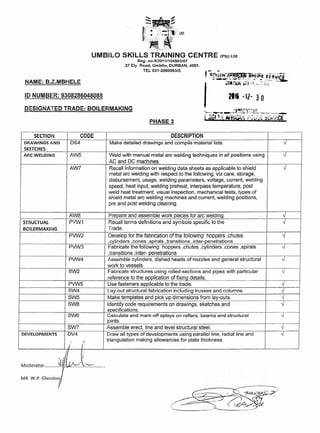

This document is a certificate awarded to B.Z. Mbhele for successfully completing the Boilermaking Course - Phase Three at Umbilo Skills Training Centre. It lists the various sections of the course, including drawings and sketches, arc welding, structural boilermaking, fabrications, developments, and structural work. It was issued on 12/03/2021 and signed by the moderator Mr. W.P. Glendon.

![r~~._ll]I ~ UMBILO SKILLS TRAINING CENTRE

~.

<-~'r .

~~"'lWt8_··Il, ., , '.,.: ••

Successfu IlyCom(lletiQ9ttleBQilermaki ng Cou rse

PHA~SETHREE

Awarded-to:

B.Z.MBHEt.E

ID NO: 9308286048085

~~:-~------,~".,,;., (;,..'~

.I 2i1i -12~ 3 •](https://image.slidesharecdn.com/2c2b0ce7-c1ff-42f5-954a-927e605c21bb-170101151450/75/Scan_Doc0007-1-2048.jpg)