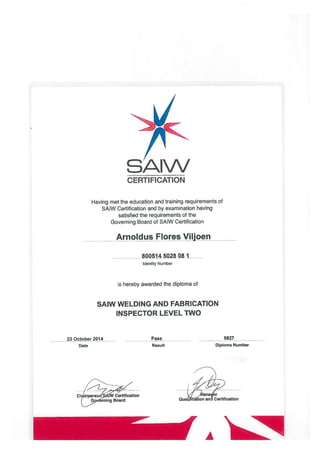

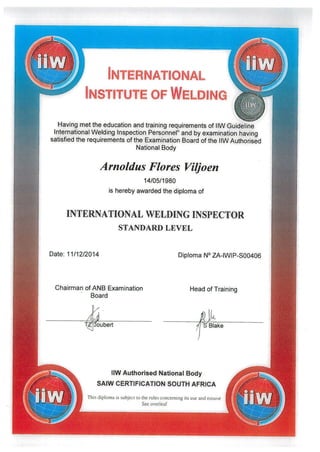

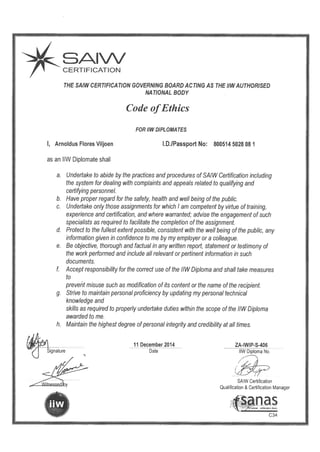

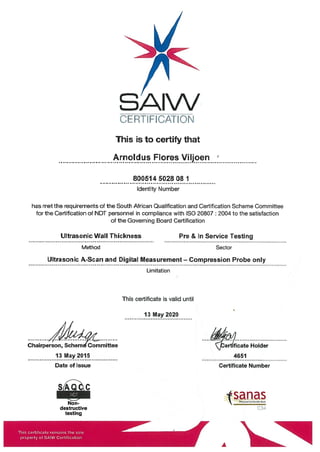

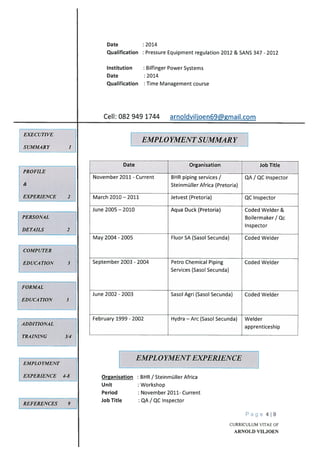

Arnold Viljoen has over 15 years of experience in welding, fabrication, inspection, and quality control. He currently works as a QA/QC Inspector for BHR Piping Systems, where he is responsible for reviewing documentation, inspecting welds, and ensuring quality standards are met on major power station projects. Arnold has a variety of technical certifications and has worked on numerous projects in the petrochemical, manufacturing, and engineering industries.

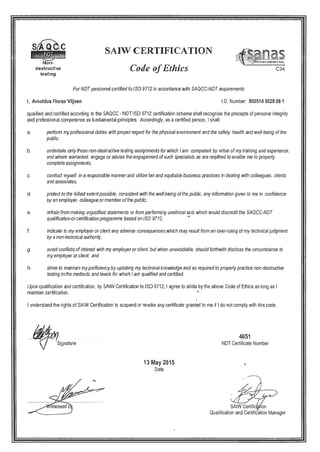

![SAIW CERTIFICATION

IIan nic thc cducaiou id uu.iun rqwirnrn[ of

siw L rd1icatkr fr,, SATW ‘V 141in 311LL rbrLi4)rI lrlcpeln4)r level Oiw

1w xuimnitiori having satUed the reuirernents o

the (c1errIt Il.oad c1A.1W CcrrifLcatiil

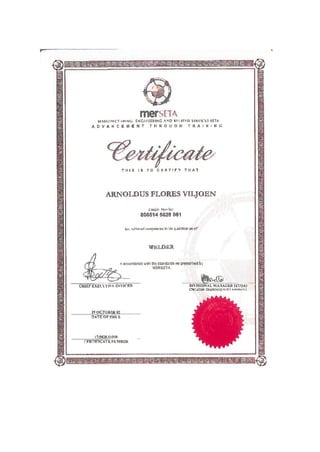

Arnoldus Flores Viljoen

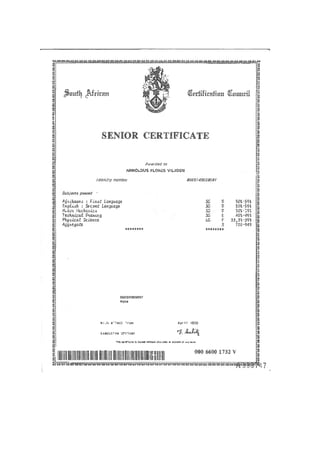

800514 502S 08 1

Idenilty NLJnit

ts hcreby i. ided thc lipkirri of

SA1W WELDING AND FABRICATION

INSPECTOR LEVEL ONE

I Febniarv 2fl10

I)atc ResulL

?9S2

flijilirn-ti Nurnbcr

SCERT

ClJiiIxtLiJ

PRDCI )tkF]illillCfl.

(hsirpr,4n

SAPV Certi1kii.ui Gutiniu Boa’d](https://image.slidesharecdn.com/c363a2d5-4ac0-473d-b2e8-520b958ef0f4-150807093448-lva1-app6892/85/DOC005-12-320.jpg)