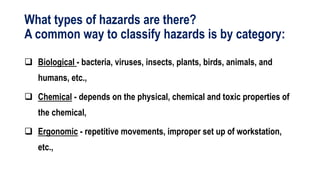

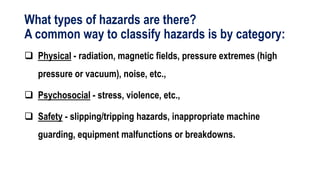

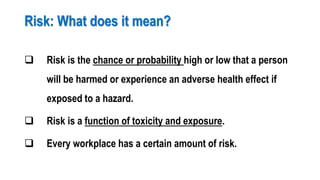

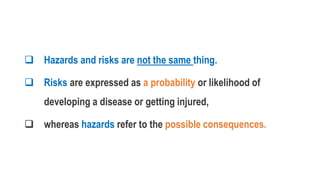

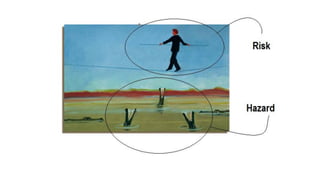

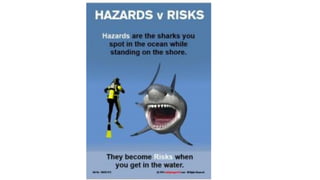

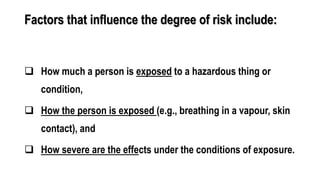

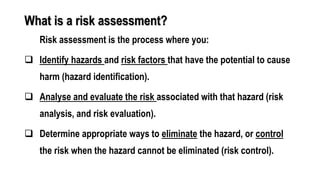

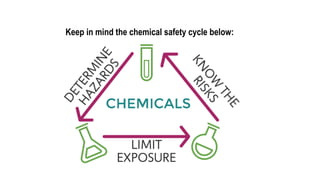

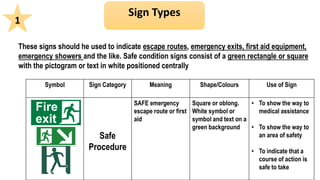

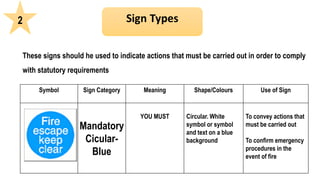

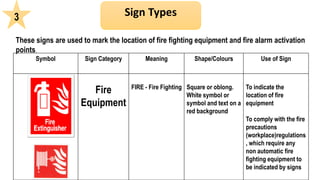

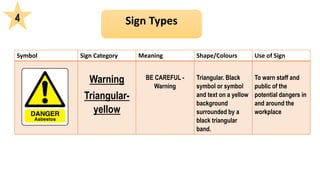

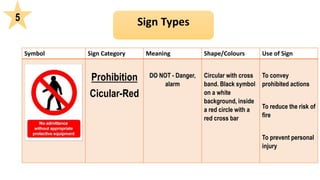

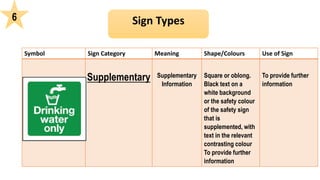

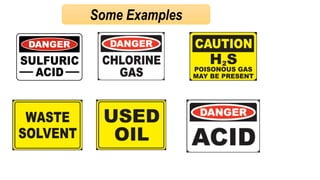

This document discusses workplace safety, focusing on hazards, risks, signs, and exposure to chemicals. It defines key terms like safety, hazard, and risk. It describes different types of hazards and provides steps for assessing and managing risks. The document emphasizes the importance of safety signs for chemicals and outlines categories of safety signs. It also discusses routes of exposure to chemicals and provides steps for transitioning to safer chemicals in the workplace.