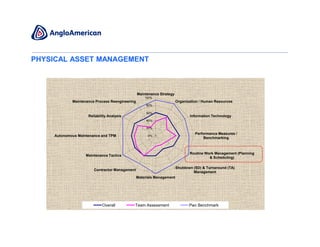

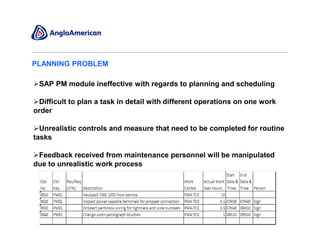

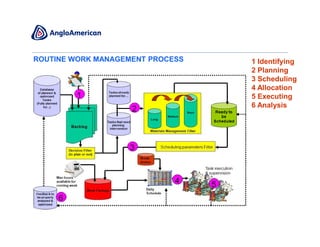

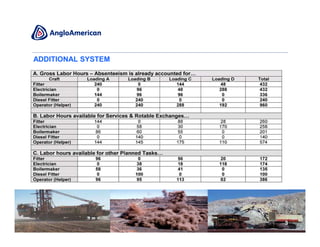

Martin Butler presented a solution to improve routine work management (RWM) at Kumba Iron Ore. The current SAP PM module was ineffective for planning and scheduling tasks or allocating resources. The solution was to develop an add-on system to calculate available man-hours and allocate resources to scheduled tasks. This would provide visibility into resource utilization and allow for optimal allocation. However, future upgrades may not include the add-on and it cannot integrate with other SAP functions for reporting. Considerations for future projects include involving ERP specialists, ensuring upgrades and a BI system for accurate reporting.