This document is a dissertation submitted by Suresh Babu E.M. for the partial fulfillment of the requirements for the degree of Master of Technology. The dissertation evaluates the mechanical and metallurgical properties of metals joined by rotary friction welding using a conventional lathe. Seven combinations of similar and dissimilar metals, including carbon steel, stainless steel, copper, and aluminum alloy, were friction welded at two spindle speeds. Tensile testing, hardness testing, and microscopic evaluation using SEM were conducted on the welded samples to analyze the weld quality and properties. The results were used to study the effect of friction welding parameters on the nature and type of fracture in the welded joints.

![8

CHAPTER 2

LITERATURE REVIEW

2.1 Introduction

In continuing the report for project “Evaluation of mechanical and metallurgical properties

of metals joined by rotary friction welding with conventional lathe”, literature review is

important in order to study the basic knowledge about the subject of the project. Literature

review is a process to search, collect, analyses and concluded all debates and issues raised

in the work that been done in the past. It also provide the examples, case studies and other

relevant work that be done by other people in the past. It gives the chance to investigate and

read the subject that user may not have thought about before. The literature review focuses

on the various theory and basic knowledge used in the project.

2.2 Fact and findings

There is lot of techniques used to gather information that related to the project through

internet, book, journal, etc. These initial documents will provide some valuable information

to determine the basic view of the project. The theory and concept from the past research,

references, case studies, and other can be applied in order to understand the dissertation.

2.3 What is friction welding?

Friction welding is a completely mechanical solid phase process in which heat is generated

by friction [1]

to produce a high integrity joint between similar and dissimilar metals.

2.4 Why friction welding?

A bonded joint is formed using no filler metal, flux or shielded gas. This process is

environmentally clean, no arcs, sparks, smoke or flames are generated during friction

welding. Surface preparation/ cleanliness are not significant with most materials since the](https://image.slidesharecdn.com/rotaryfrictionweldingbyconventionallathe-mtechproject-221023182204-a2ff3487/75/ROTARY-FRICTION-WELDING-BY-CONVENTIONAL-LATHE-MTECH-PROJECT-pdf-22-2048.jpg)

![9

process burns through and displaces surface impurities. During the friction welding process

there are narrow heat affected zones. This process is suitable for welding most engineering

materials and is well suited for joining many dissimilar [2][6]

combinations. In most cases, the

weld strength is strong or stronger than [3]

the weaker of the two materials being joined.

Operators are not required to have manual welding skills. Friction welding only required

simple integration into the manufacturing area. This process can be easily automated for

mass production. Welds are made rapidly compared to other welding processes. Plant

requirements (space, power, special foundation, etc.) are minimal for the friction welding

process.

2.5 Theory of friction welding

Friction welding consists of a complex of interrelated processes; heat generation and

dissipation and abrasion of common surfaces due to friction [4]

; plastic deformation, cold

working and recrystallization of metal heated to high temperatures; inter diffusion [5]

of

metal and penetration of macroscopic metal parts from one piece into other; continuous

formation and destruction of connections between the friction surfaces, etc.

2.6 History of the friction welding

According to the American Welding Society, the origins of friction welding date back to

1891, when the first patent on the process was issued in the USA. More work progressed

throughout Europe as more patents were issued from 1920 to 1944 and in the Soviet Russia in

1954. In 1954, this technique has successfully implemented by A.I. Chudikov from Russia

(USSR) with a modified lathe using round metal bars. In the 1960's, friction welding was

further developed in the USA by AMF, Caterpillar, and Rockwell International. Rockwell

built its own machines to weld spindles to truck differential housings, AMF produced

machines to weld steering worm shafts, and Caterpillar‟s machines welded turbochargers and

hydraulic cylinders.

Friction has been used to weld parts for both new make and for repair for many years. The

friction welding family has many different variants, including rotary friction welding (direct

drive, inertia, and hybrid), linear friction welding, and more recently, friction stir welding

(FSW). In e ach case, friction heats the material to a plastic state in conjunction with an](https://image.slidesharecdn.com/rotaryfrictionweldingbyconventionallathe-mtechproject-221023182204-a2ff3487/75/ROTARY-FRICTION-WELDING-BY-CONVENTIONAL-LATHE-MTECH-PROJECT-pdf-23-2048.jpg)

![10

applied force to create the weld. Friction welding often produces welds with superior

mechanical properties to that of the parent materials. The weldment produced by this method

often has less distortion than fusion welding methods (such as arc welding, laser welding,

etc.) In addition that dissimilar material combination can be welded that are not possible with

fusion welding processes.

2.6.1 Historical development in friction welding

A historical development [14]

in friction welding is explained in the Table 2.1 below.

Table 2.1 – Historical development in friction welding

1954

A.I. Chudikov of U.S.S.R. succeeded in the experiment of friction welding,

using a modified lathe and round metal bars. U.S.S.R. Electric Welding

Machine Research Institute took up the idea and started the research and

development from around 1956.

1956

U.S.S.R. Electric Welding Machine Research Institute took up the idea and

started the research and development.

1957

The Institute developed and made public the friction welding machine MST-1.

After this announcement, many countries started research and development of

the technology for practical applications.

1958

Development in U.S.S.R. entered the stage that the technology was introduced

in the production processes.

1958

British Welding Research Association (BWRA) succeeded to produce a

prototype of friction welding machine. AMF Corp. of the U.S. also introduced a

prototype of friction welding.

1960

"Friction joining of metals" by VILL of VNIIESO was introduced as a research

data in Japan. This triggered ardent investigations and researches on the friction

joining.

1960

Machine tool research group brought back useful information from the USSR

designed, manufactured and started marketing specialized manufacturing

equipment.

1962

Toyoda Automatic Loom Works Ltd. developed the first brake-type friction

welding machine for commercial industrial use in Japan

1964

The Friction Joining Research Conference was founded. It was renamed later as

the Society for the Study of Friction Joining and further to the Friction Joining

Association, which continues activities to now.

1973

Izumi Machine Mfg. Co. of Japan began consignment manufacturing of Toyoda

Automatic Loom Works, Ltd friction welding equipment.](https://image.slidesharecdn.com/rotaryfrictionweldingbyconventionallathe-mtechproject-221023182204-a2ff3487/75/ROTARY-FRICTION-WELDING-BY-CONVENTIONAL-LATHE-MTECH-PROJECT-pdf-24-2048.jpg)

![11

1994 JIS 3607 Standard for the friction joining work of carbon steel was enacted.

1998

Izumi started commercial application of a friction welding machine

incorporating NC control that is compatible with the production of propeller

shafts and other parts.

2002

Izumi started commercial application of a friction welding machine capable of

use on extremely small diameter material (Ø1.6) used for drills, sensor shafts

and other such applications.

2004 Friction welding of plastics

2006 Scientific Optimization Techniques used to study friction welding

2009 Use of interlayers during friction welding

2011 Response surface methodology used to study friction welding

2014 Friction welding of 3D printed objects [15]

2015

Austrian premium chain manufacturer Pewag presented its newly developed

Pewag Hero Friction-welded chain. This innovation marks the starting point of

a new era in chain manufacturing.

2.7 Research work on friction welding

Table 2.2 shows some of the latest research work related to friction welding [1-12].

Table 2.2 – Recent research work on friction welding

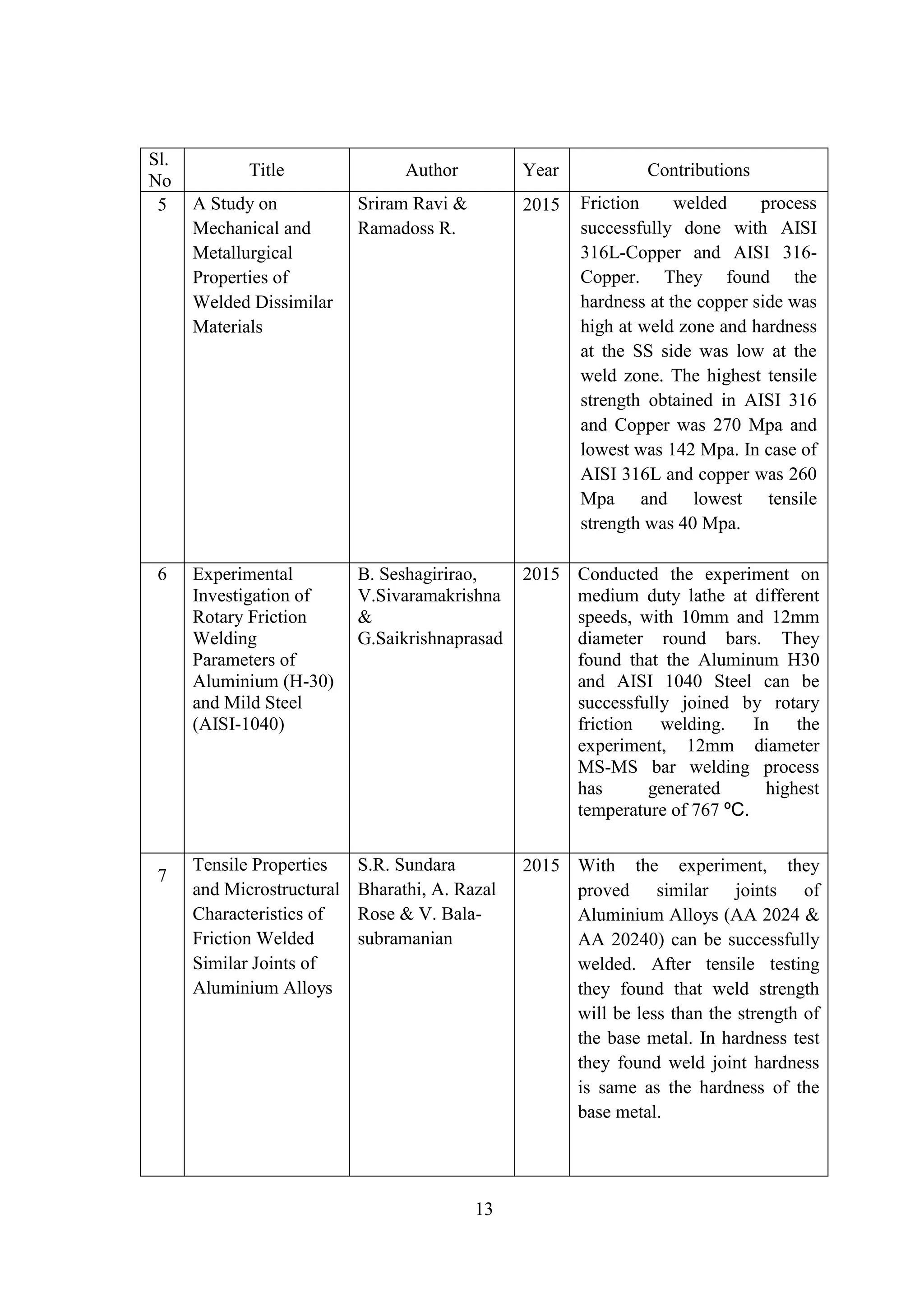

Sl.

No

Title Author Year Contributions

1 Friction Welding

Process of

Aluminium 5083

Alloy with Mild

Steel.

V. Ganesh,

N. Parthasarathi, M.

Sivanesh,

S. Pravin Joseph

Rajkumar &

P. Giftan Samuel

2016 Conducted the experiment with

combination of Aluminium

5083 and Mild Steel and they

found that the friction welding

was very successful.](https://image.slidesharecdn.com/rotaryfrictionweldingbyconventionallathe-mtechproject-221023182204-a2ff3487/75/ROTARY-FRICTION-WELDING-BY-CONVENTIONAL-LATHE-MTECH-PROJECT-pdf-25-2048.jpg)

![15

Sl.

No

Title Author Year Contributions

12 An Experimental

Assessment of the

Bond Strength of

Friction Weldment

Between AA-6061

and AA-6351

S Thileepan,

S. yuvanarayanan,

S. Jayakumar,

Vasanthan &

R. Adalarasan

2011 Conducted the rotary friction

welding between Aluminium

Alloy AA-6061 and AA-6351 on

friction welding machine. The

diameter of the test specimen was

18mm. The hardness at the

weldment was higher than the

hardness of the base metals.

Hardness of the weldment

increases with increase in

rotational speed.

2.8 Material combinations weldable by friction welding [20]

The data given in the figure 2.1 shows the possible combination of similar and dissimilar

materials that can be joined by friction welding.](https://image.slidesharecdn.com/rotaryfrictionweldingbyconventionallathe-mtechproject-221023182204-a2ff3487/75/ROTARY-FRICTION-WELDING-BY-CONVENTIONAL-LATHE-MTECH-PROJECT-pdf-29-2048.jpg)

![16

2.9 Friction welded components and their applications [18]

2.9.1 Aerospace Industry

Aerospace heat pipe

(Aluminium)

Piston for aircraft pump

(Stainless steel)

Aircraft hook bolt

(Nickel-heat resistant)

Stator vane adjustor lever

(Titanium)

Ball screw actuator

(Steel-Medium carbon

alloy)

Jet engine fan shaft

(Nickel-heat resistant)

Landing gear component

(Steel-Medium carbon

alloy)

Fan blade rotor

(Nickel-heat resistant)

Cluster gear

(Steel-Low carbon alloy

(gear steel))

Fig. 2.2 - Friction welded components and their applications in

Aerospace industry](https://image.slidesharecdn.com/rotaryfrictionweldingbyconventionallathe-mtechproject-221023182204-a2ff3487/75/ROTARY-FRICTION-WELDING-BY-CONVENTIONAL-LATHE-MTECH-PROJECT-pdf-30-2048.jpg)

![21

2.10 Variables and parameters that govern the quality of the

welded components

The variables and parameters [20]

that govern the quality of the welded components during

continuous drive rotary friction welding are given in the Table 2.3 below.

1) Frictional pressure: The pressure applied normal to the faying surfaces during the

time that there is relative movement between the components.

2) Forging pressure: The pressure applied normal to the faying surfaces at the time when

relative movement between the components is ceasing or has ceased.

3) Friction time: The time during which relative movement between the components takes

place at rotational speed and under application of the friction force.

4) Braking time: The time required by the moving component to decelerate from friction

speed to zero speed.

5) Forge time: The time for which the forge force is applied to the components.

6) Linear feed: This is the lateral movement of the stationary work-piece relative to the

rotation of the rotating work-piece.

7) Medium in which process takes place: This will depend upon the site conditions.

Sometimes friction welding can be done in the air conditioned atmosphere or in vacuum

chambers. The result will be something different.

Sl. No.

Machine Material

1 Friction pressure Type of metal

2 Forging pressure Part configuration

3 Friction time Size

4 Braking time Initial condition of the friction surface

5 Forge time Shape of the parts to be welded

6 Linear feed

7 Medium in which process takes place

Table 2.3 - Variables and parameters govern the quality of the friction weld](https://image.slidesharecdn.com/rotaryfrictionweldingbyconventionallathe-mtechproject-221023182204-a2ff3487/75/ROTARY-FRICTION-WELDING-BY-CONVENTIONAL-LATHE-MTECH-PROJECT-pdf-35-2048.jpg)

![22

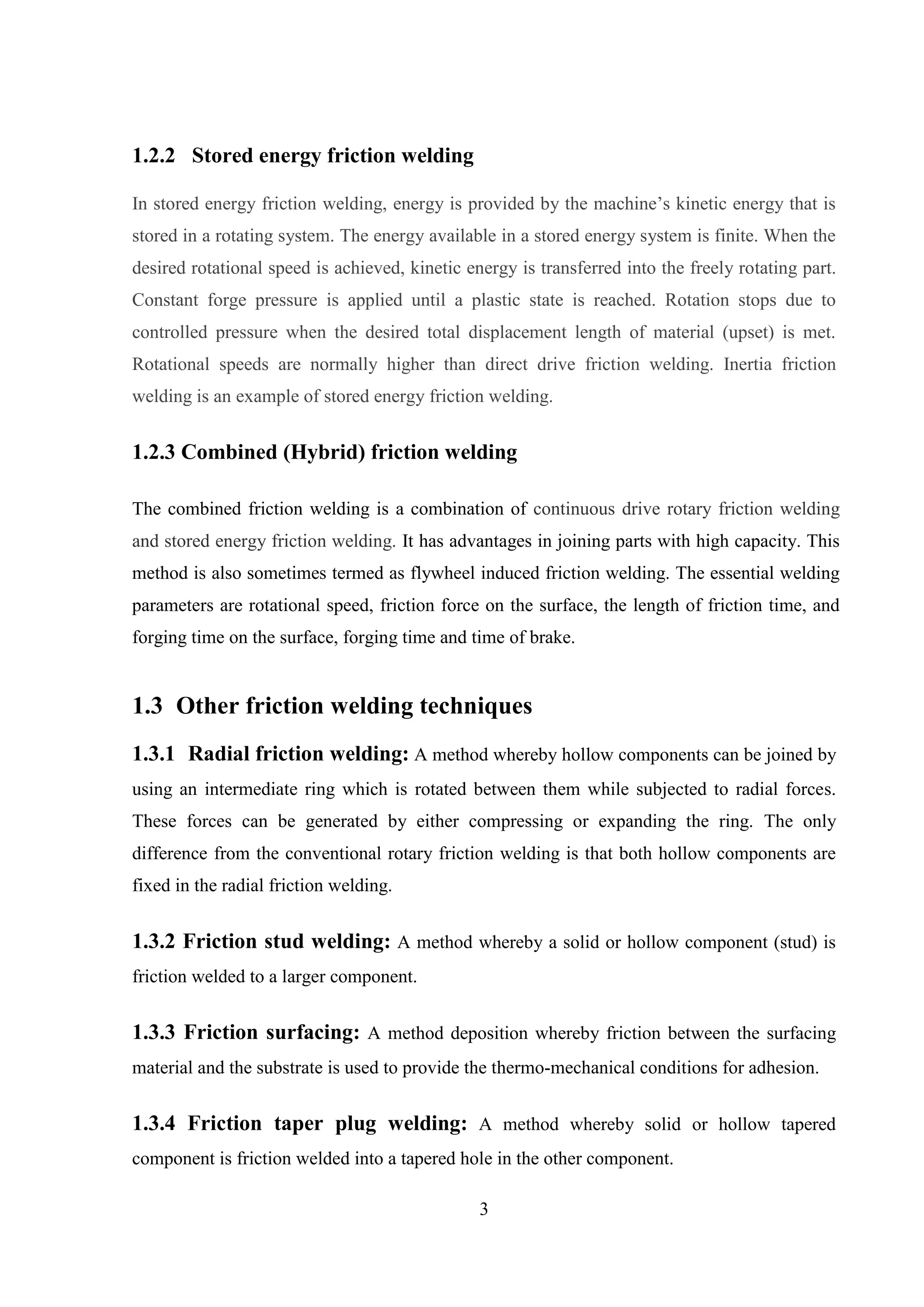

2.11 Plot of Welding parameters versus Time in continuous drive

friction welding

Fig. 2.7 shows the generalized plot of the „welding parameters versus time‟ in continuous

drive friction welding process [21]

.](https://image.slidesharecdn.com/rotaryfrictionweldingbyconventionallathe-mtechproject-221023182204-a2ff3487/75/ROTARY-FRICTION-WELDING-BY-CONVENTIONAL-LATHE-MTECH-PROJECT-pdf-36-2048.jpg)

![23

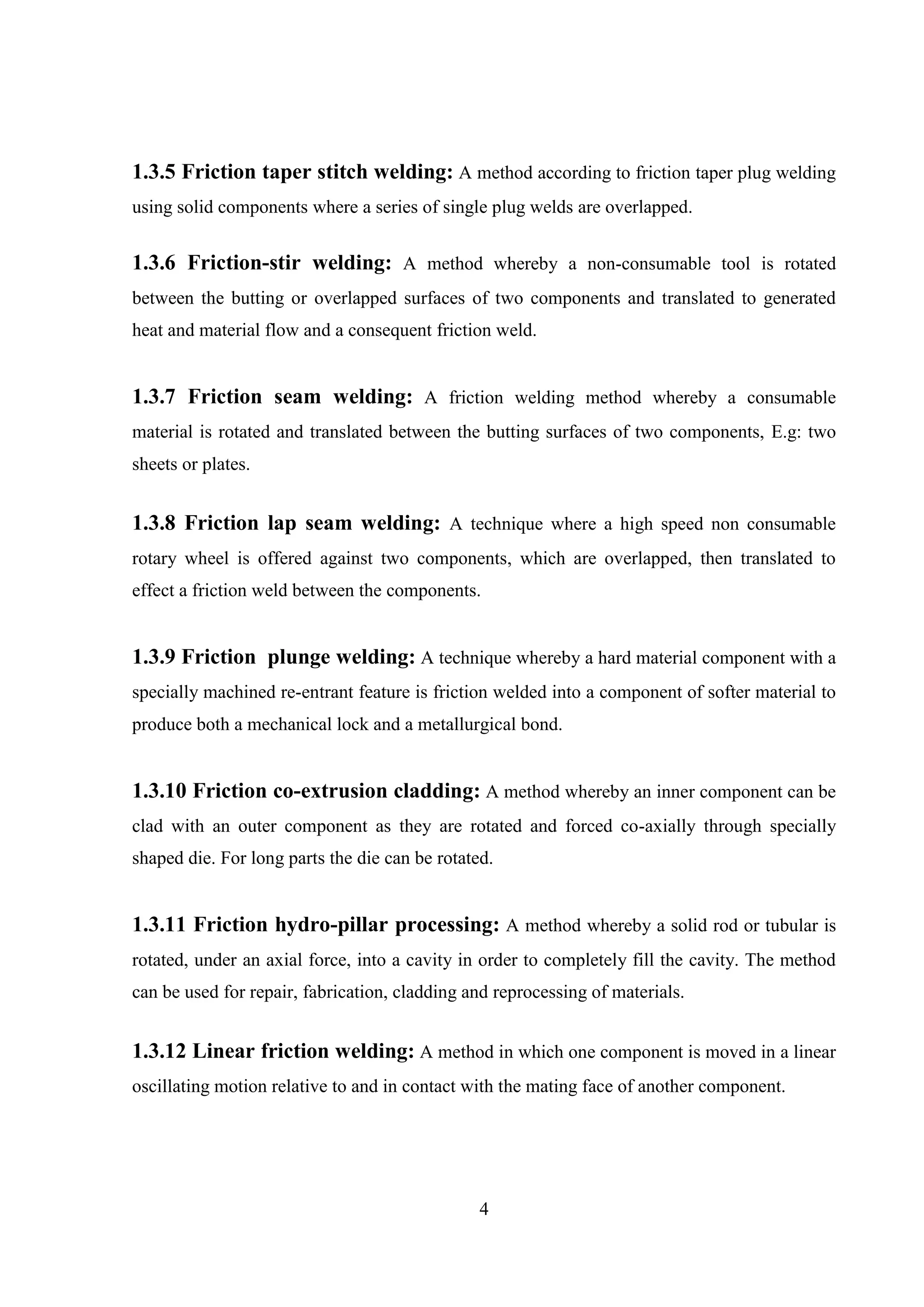

2.12 Characteristics of friction welded components[20]

Possible friction welded defects, causes, remedies, etc. are illustrated in the Table 2.4.

Table 2.4 – Characteristics of friction welded components

Desig-

nation

Explanation Diagram Usual test

methods

Causes Remedy Remarks

1) Shape deviation

Axial

mis-

alignment

Misalign-

ment of

parallel

axes of

components

Measure-

ment, visual

examination,

macroscopic

Clamps,

geometrical

inaccuracy,

overhang too

long, poor

component

preparation,

angularity

Adjustment

of clamps,

check

component

geometry,

reduce free

length,

better

component

preparation

Critical when

friction

welding thin

walled tubes

and materials

which are

very

dissimilar

Angular

deviation

Axes of

components

misaligned

Measure-

ment, visual

examination

Clamping

length

too short,

overhang too

long,

loose clamps,

axial force

too great

Improve

clamping,

decrease

free length,

tighten

clamps,

reduce axial

force

Critical

mainly when

thin-walled

tubes

Parts

overlying

Lateral

deviation of

one or both

work pieces

Visual

examination,

macroscopic

Welding

parameters,

component

geometry,

overhang too

long, axial

misalignment

Work piece

preparation,

angularity

Change Critical

mainly when

friction

welding thin

walled tubes

and

components

of very

dissimilar

materials

Deforma-

tion of

work

pieces

Undesired

Change in

geometry

Measure-

ment, visual

examinations

Insufficient

support, axial

strength too

high,

overhang too

long, tooling

wear

Adjust

clamping,

increase

rigidity

Occurs when

welding thin

walled work

pieces](https://image.slidesharecdn.com/rotaryfrictionweldingbyconventionallathe-mtechproject-221023182204-a2ff3487/75/ROTARY-FRICTION-WELDING-BY-CONVENTIONAL-LATHE-MTECH-PROJECT-pdf-37-2048.jpg)