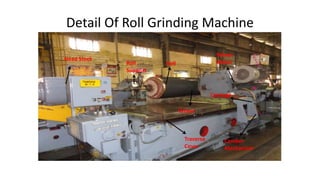

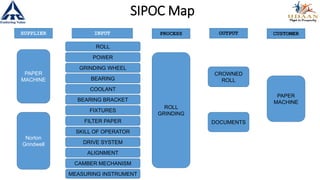

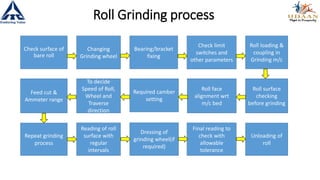

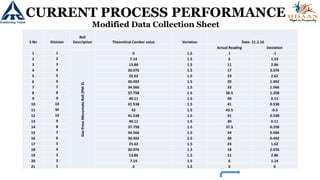

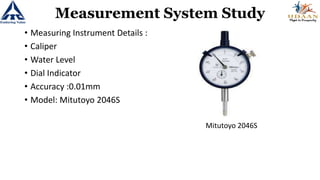

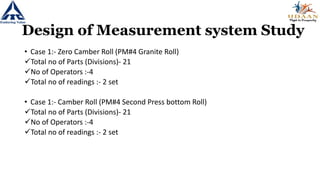

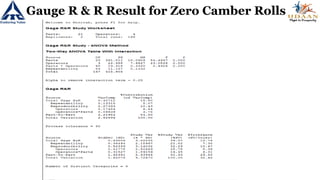

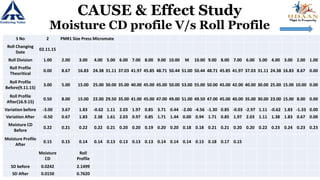

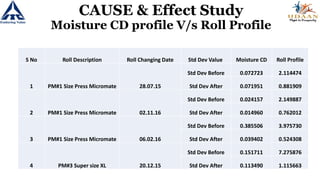

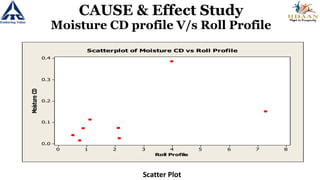

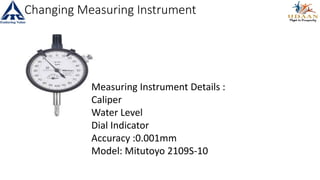

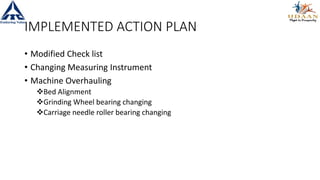

The document summarizes a project to improve the Cp and Cpk of roll crowning through reducing variation in roll profiles. It outlines the current process performance including high standard deviation and sigma rating of 1.11-2.76. Modifications were made to the data collection process and a measurement system study was conducted to analyze gauge repeatability and reproducibility. A cause and effect study identified a relationship between roll profile variation and moisture content deviation in the paper. The goal is to improve the sigma rating from the current 2.25 to 2.65 through applying DMAIC methodology to identify and implement solutions.