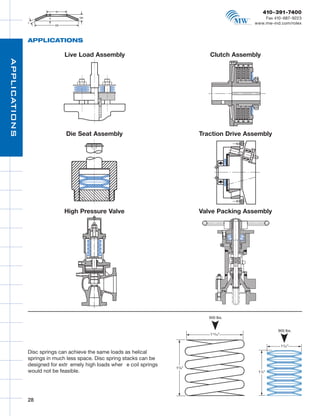

Rolex Spring is introducing its 2009 catalog, which features a redesigned format. Rolex Spring has relocated its production facility to a sister division, Maryland Precision Spring in Baltimore, and invested in new production and heat treating equipment to streamline manufacturing processes. Rolex Spring can continue to rely on quality disc springs for various industries such as aviation, transportation, and machinery. The catalog provides information on Rolex Spring's products, services, and standard spring series.